Organic electroluminescent device

An electroluminescent element and organic technology, applied in electroluminescent light sources, electrical components, electric light sources, etc., can solve problems such as low stability, difficult operation, and reduced component performance, and achieve long life and less brightness reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

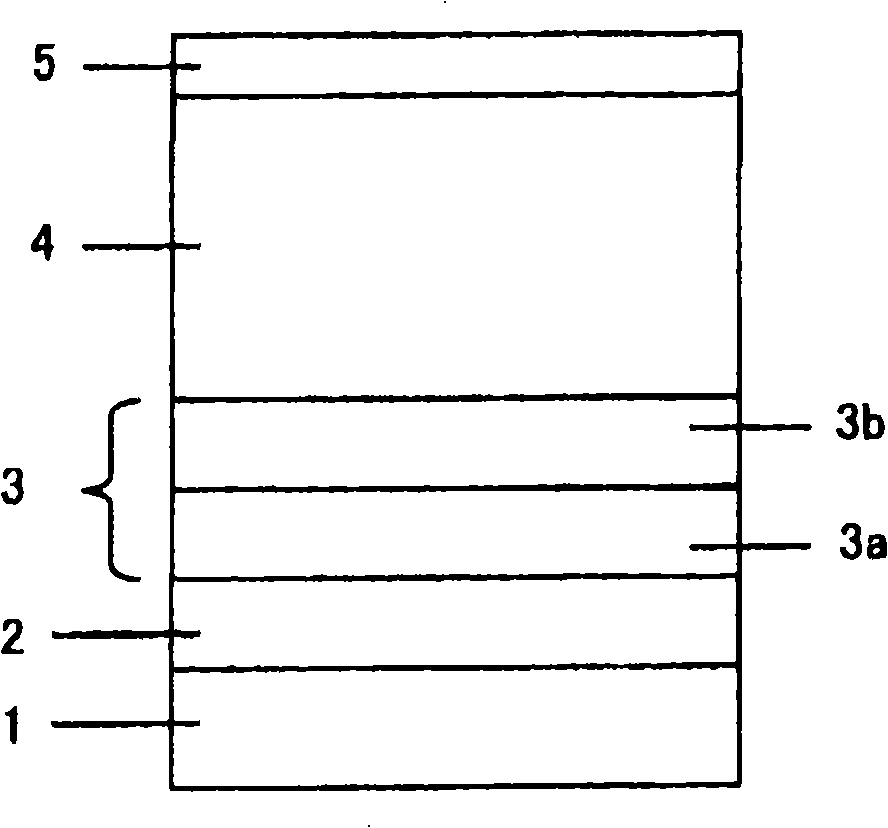

[0177] have Figure 5 An organic EL device with the basic structure shown was produced by the following method.

[0178] (formation of anode)

[0179] First, a 110 nm indium tin oxide (ITO) transparent conductive film is deposited on a glass substrate, and the deposited product (sputtered film product) is patterned with 2 mm wide stripes by normal photolithography and etching to form an anode.

[0180] For this patterned ITO substrate, ultrasonic cleaning by pure water and surfactant, running water washing by pure water, ultrasonic cleaning by a 1:1 mixed solution of pure water and isopropanol, washing by isopropanol The washing treatment was performed in the order of boiling washing with propanol. The substrate was slowly lifted from boiling isopropanol, dried in isopropanol vapor, and finally subjected to ultraviolet ozone washing.

[0181] The substrate was arranged in a vacuum evaporation device, and the inside of the device was exhausted to a vacuum degree of 5.0×10 us...

Embodiment 2

[0208] The molybdenum boat made of molybdenum that is added with the electron-transporting material (BAlq) shown in the following (chemical formula 18) is energized and heated, and the degree of vacuum is 1.9×10 -5 Pa, the evaporation rate is Evaporate on the anode ITO under the condition that the film thickness is 5nm, and change the film thickness from 10nm to 5nm on it. 3 An organic EL element was produced in the same manner as in Example 1 except that the domain of the first electron transporting material of Liq = 3:1.

[0209] [chemical formula 18]

[0210]

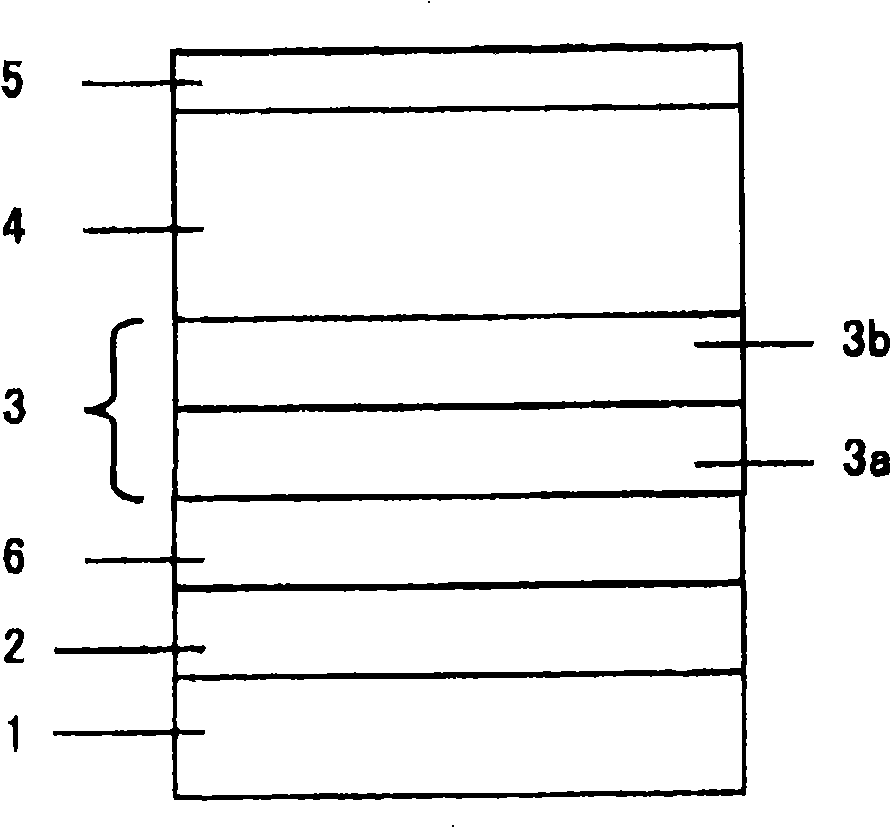

[0211] If the layer structure of the component is briefly expressed, it is:

[0212] ITO / BAlq(5nm) / Alq 3:Liq(5nm, 3:1) / Al(1.5nm) / α-NPD:MoO 3 (10nm, 4:1) / α-NPD(40nm) / Alq 3 : C545T (30nm, 100:1) / Alq 3 (34nm) / Alq 3 : Liq (10nm, 3:1) / Al (100nm).

Embodiment 3

[0214] Between the region containing the first electron-transporting material and the region containing the first hole-transporting material, the degree of vacuum is 4.7×10 -5 Pa, the evaporation rate is Evaporated MoO with a film thickness of 10nm 3 , and an organic EL element was produced in the same manner as in Example 1 except that a hole transport layer containing α-NPD was formed in a film thickness of 30 nm.

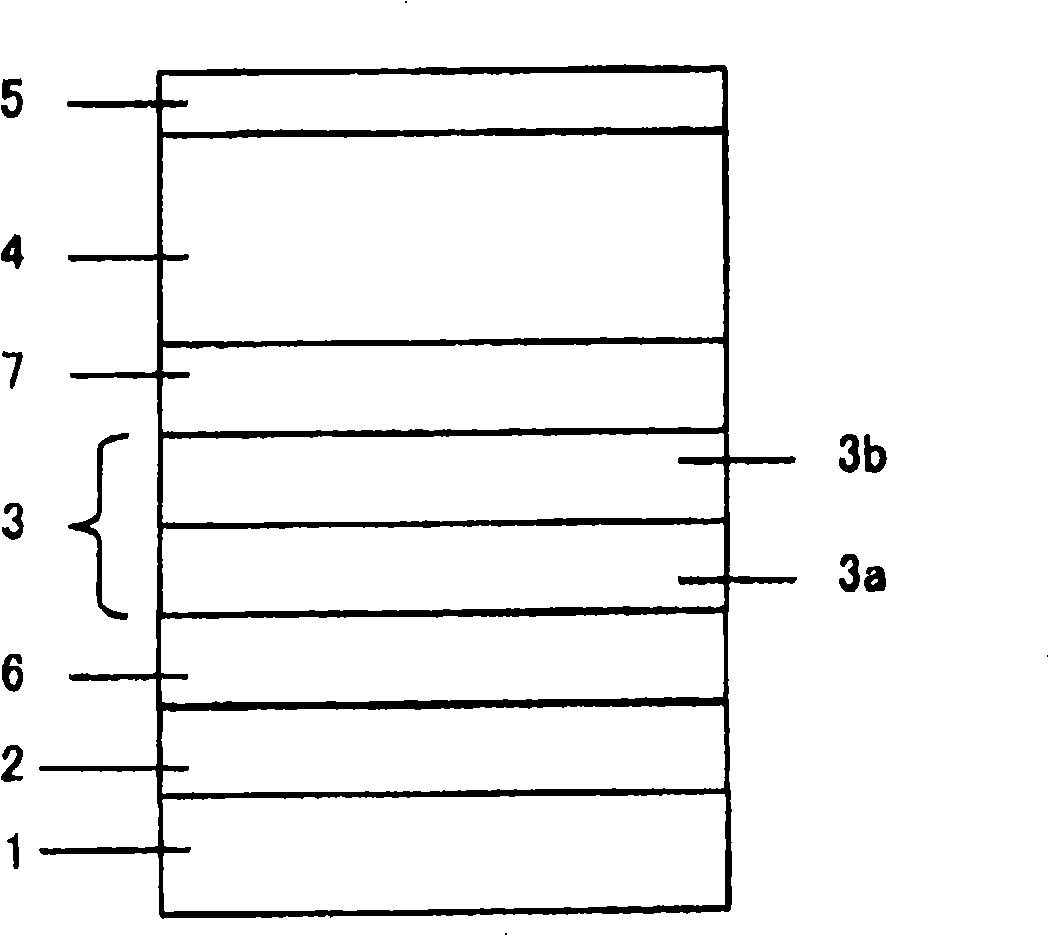

[0215] If the layer structure of the component is briefly expressed, it is:

[0216] ITO / Alq 3 : Liq(10nm, 3:1) / Al(1.5nm) / MoO 3 (10nm) / α-NPD:MoO 3 (10nm, 4:1) / α-NPD(30nm) / Alq 3 : C545T (30nm, 100:1) / Alq 3 (34nm) / Alq 3 : Liq (10nm, 3:1) / Al (100nm).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com