Hole injection material for organic electroluminescent device

A technology for electroluminescent devices and hole injection materials, which is applied in neutral or alkaline aqueous solutions and weakly acidic fields. Effects of hole transport ability and luminescent properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

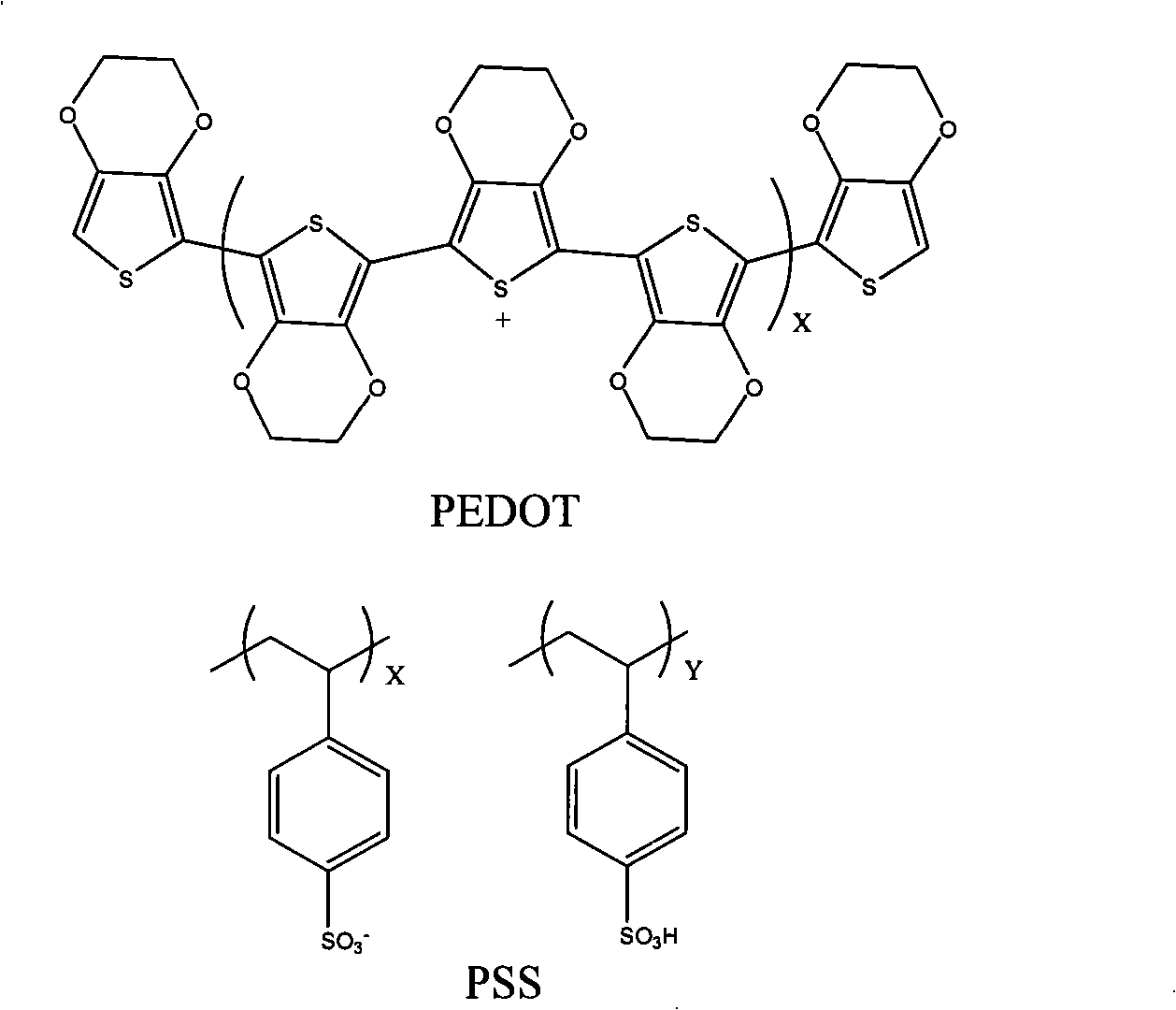

[0026] In this example, the effects of PEDOT:PSS acidity and alkalinity on the performance of OLEDs whose hole transport layers are small molecules are studied. In order to obtain PEDOT with different pH:PSS, the present embodiment adopts following method:

[0027]Dilute the commercially available PEDOT:PSS stock solution (produced by Aldrich, PEDOT: 0.14w.t.%, PSS: 2.6w.t.%) at a ratio of 1:5 (volume ratio before and after), and divide the diluted solution into five parts, using NaOH solution as The lye was used to adjust the pH of the above solution to obtain five parts of PEDOT:PSS solutions with pHs of 3.0 (without adding NaOH), 5.4, 7.6, 10.0 and 13.0, respectively.

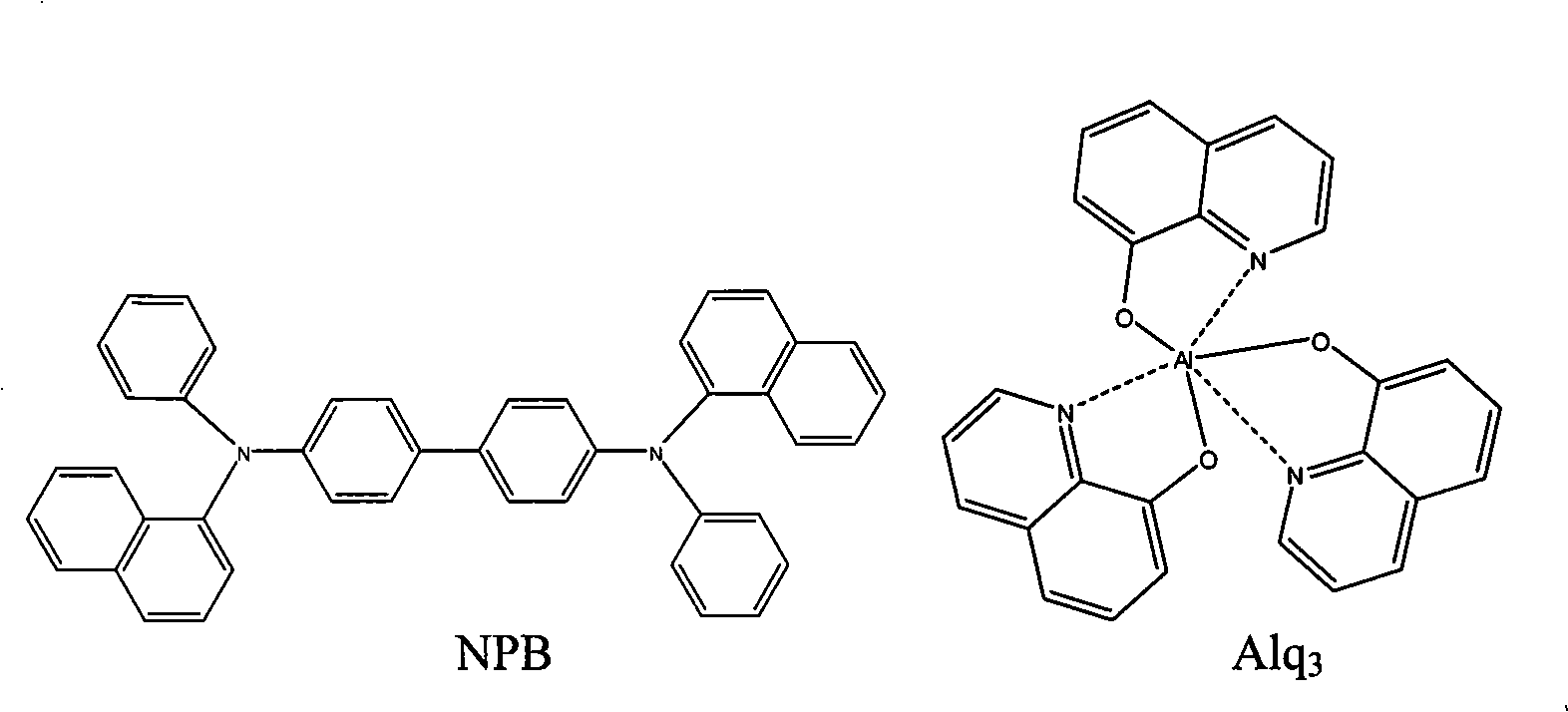

[0028] The OLED prepared in this example has a structure of ITO / PEDOT:PSS / NPB / Alq 3 / LiF / Al standard OLED, such as Figure 4a shown. The full name of NPB is N,N'-bis-(3-naphthyl)-N,N'-diphenyl-[1,1'-diphenyl]-4,4'-diamine (N,N' -diphenyl-N, N'-bis(1,1'-biphenyl)-4,4'-diamine), Alq 3 The full name is 8-h...

Embodiment 2

[0038] This example studies the effect of PEDOT:PSS acidity and alkalinity on the performance of OLEDs whose hole transport layer is a polymer. The pH of the PEDOT:PSS is 3.0, 7.6 and 13.0 respectively, and its preparation method is the same as in Example 1.

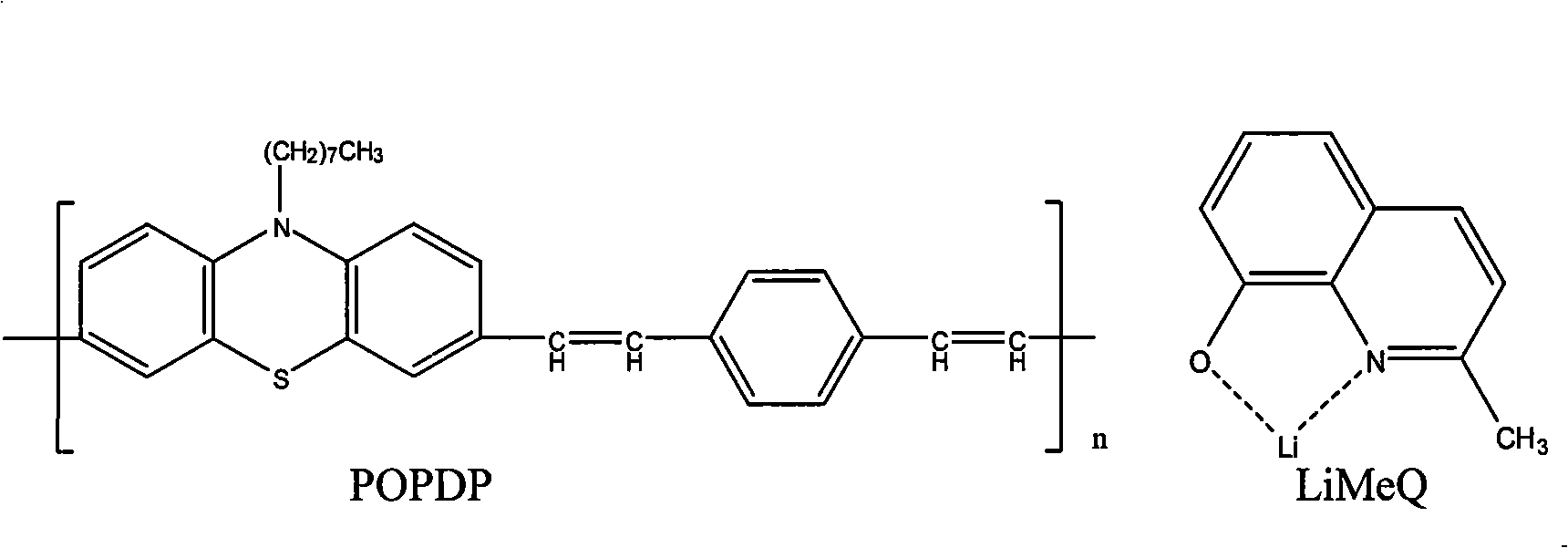

[0039] The structure of the OLED prepared in this embodiment is ITO / PEDOT:PSS / POPDP / LiMeQ / LiF / Al, such as Figure 4b shown. Among them, the full name of POPDP is N-octyl-3,7-thiazine-2,5-furylidene, and the full name of LiMeQ is 2-methyl-8-hydroxyquinolatolithium (2-Methyl-8-hydroxyquinolinolatolithium), Their structures are as image 3 shown.

[0040] The preparation method of above-mentioned OLED is identical with embodiment 1, difference is:

[0041] Step c) Spin-coat POPDP on the PEDOT:PSS hole injection layer as the hole transport layer and light-emitting layer, wherein POPDP is doped with NPB at a ratio of 1:1 to enhance its hole transport ability and reduce the yellow light material POPDP The fluorescence que...

Embodiment 3

[0045] In this example, the effect of PEDOT:PSS with different pH values on the hole injection capability of OLEDs is studied. The pH of the PEDOT:PSS is the same as in Example 1.

[0046] Both the cathode and the anode of the OLED in this embodiment use electrodes with high work function, so that only holes can be injected, and its structure is ITO glass / PEPOT:PSS / gold, such as Figure 4c shown.

[0047] The preparation method of above-mentioned OLED is identical with embodiment 1, difference is:

[0048] Step c) vapor-deposit gold on the PEDOT:PSS hole injection layer as metal cathode and electron blocking layer, the rate is Thickness is At the same time there are no subsequent steps d), e) and f).

[0049] Figure 9 The current density-voltage diagrams of five OLEDs prepared by the above method are given. It can be seen from the figure that the current density of the device prepared by using alkali-modulated PEDOT:PSS is significantly higher than that of the devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com