Coupling process of marsh gas fermentation and culture of autotrophic freshwater microalgae

A technology for biogas fermentation and microalgae cultivation, which is applied in the fields of biogas fermentation and self-supporting freshwater microalgae cultivation, can solve the problems of high cost, waste gas and waste liquid, etc., and achieve the effects of reducing production costs, improving the environment and increasing the economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The microalgae Neochloris oleoabundans (purchased from UTEX algae collection center in the United States, UTEX#1185) in this example is an autotrophic freshwater alga, and the total oil content in the BG11 medium can reach more than 45% of the dry biomass, which is rich in oil Microalgae. Biogas and biogas slurry were used as all nutrient sources for Neochloris oleoabundans, and algal cells were cultured in a small indoor tubular photobioreactor at room temperature. The algae have been experimentally confirmed to survive under these conditions. The steps are as follows:

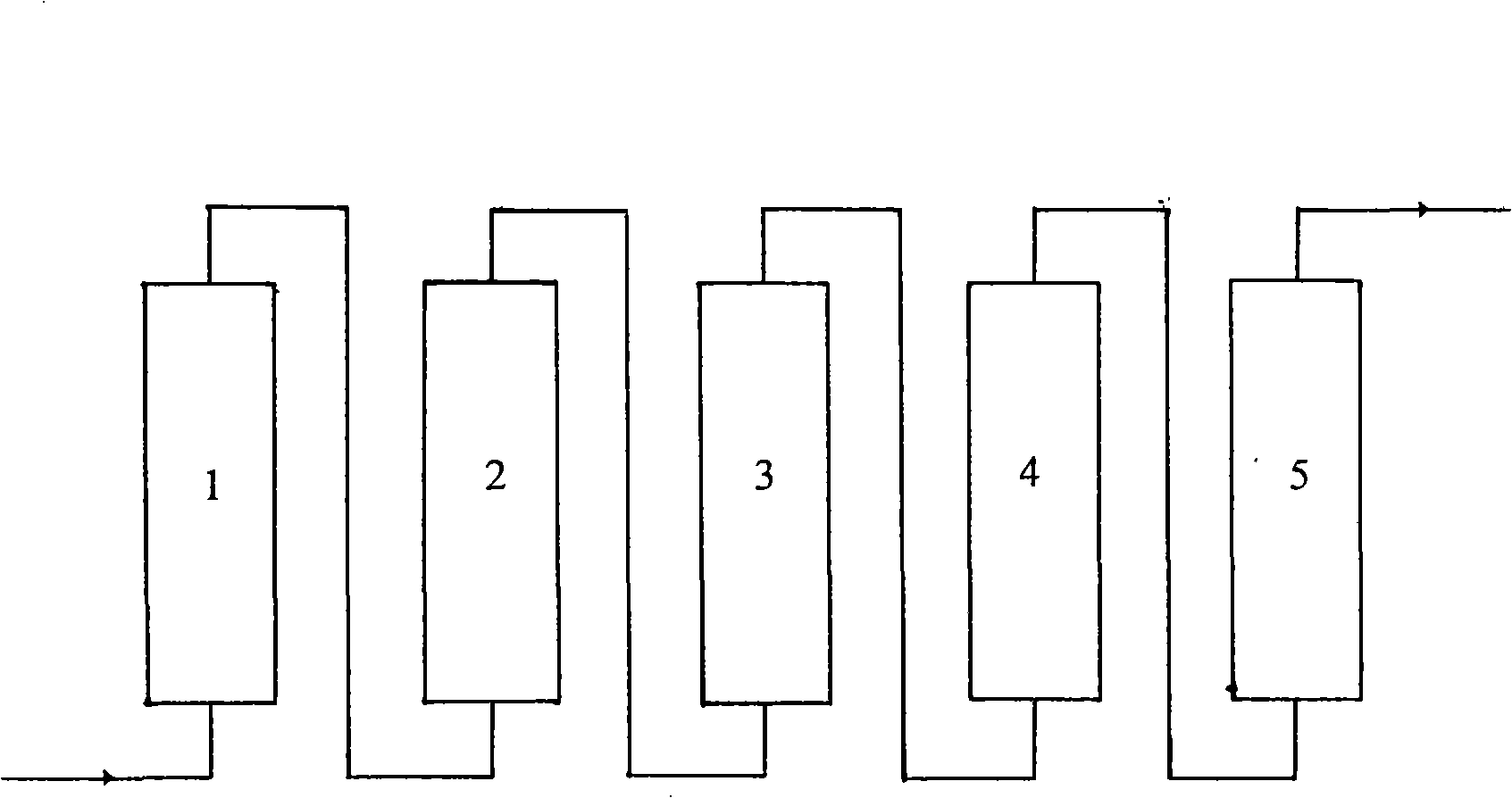

[0028] A: Biogas fermentation—mix waste biomass such as human and animal manure and domestic waste with water at a ratio of 1:19, add 30% anaerobic activated sludge, and anaerobic fermentation at 35°C for 25 days to obtain biogas and biogas slurry, biogas It is introduced into the photobioreactor through the pipeline, and the biogas slurry is treated as a culture medium.

[0029] B: Treatment of bio...

Embodiment 2

[0035] Using photoautotrophic Ankistrodesmus pseudobraunii (purchased from UTEX algal species collection center, UTEX#LB 1380) as microalgae species, using biogas and biogas slurry as all nutrient sources for the algae, small-scale pipeline photobiology at room temperature The algal cells are grown in the reactor. The algae have been experimentally confirmed that they can survive in biogas slurry as the only medium, and are oil-rich microalgae. The steps are as follows:

[0036] A: Biogas fermentation—mix water hyacinth, human and animal manure, domestic waste and other waste biomass with water at 1:20, add 10% by weight to anaerobic activated sludge, anaerobic fermentation at 35°C for 20 days, Obtain biogas and biogas. The biogas is introduced into the photobioreactor through the pipeline, and the biogas slurry is treated as a culture medium.

[0037]B: Treatment of biogas slurry - take the biogas slurry after biogas fermentation, remove residual solid particles by absorbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com