Construction method of heat-storing and energy saving block for external insulation of shear wall

A shear wall and block technology, applied in the direction of heat preservation, walls, building materials, etc., can solve the problems of easy conduction, the wall cannot achieve heat preservation, heat insulation, etc., to eliminate cold and heat bridges, improve heat preservation effect, heat preservation, etc. Excellent workmanship and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The insulation boards (2, 6, 6') used in the present invention are polystyrene foam boards.

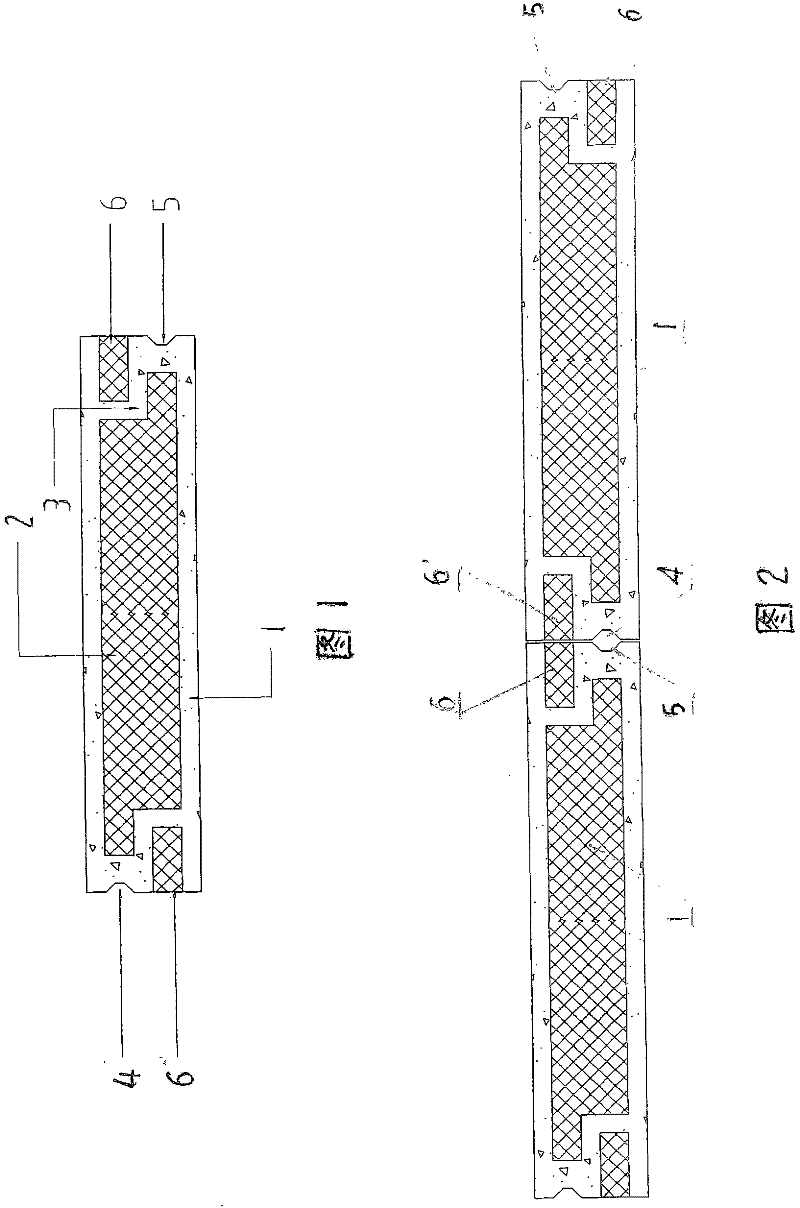

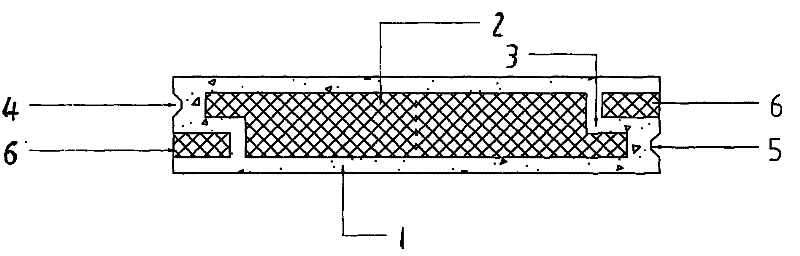

[0022] Such as Figure 1 ~ Figure 3 As shown, a thermal insulation and energy-saving block is made of 230 kg of 42.5 ordinary Portland cement, cement as the cementitious material, and 750 kg of various light aggregates (that is, 500 kg of industrial waste slag, 30 kg of waste bricks) Slag, 100 kilograms of ceramsite, 50 kilograms of perlite, 70 kilograms of hard shell waste polyphenylene particles, etc.) are used as filling aggregates, mixed with 18 kilograms of mortar anti-cracking and shrinkage reduction external admixtures and 2 kilograms of sodium dodecylbenzenesulfonate, The fluidized lightweight concrete with excellent thermal performance is mixed with water, and then it is formed by one-time pouring through the special group mold (ZL02254811.4) and the polystyrene foam board as a whole without gaps. The thermal insulation board 2 is in the shape of a "Z" in the section ...

Embodiment 2

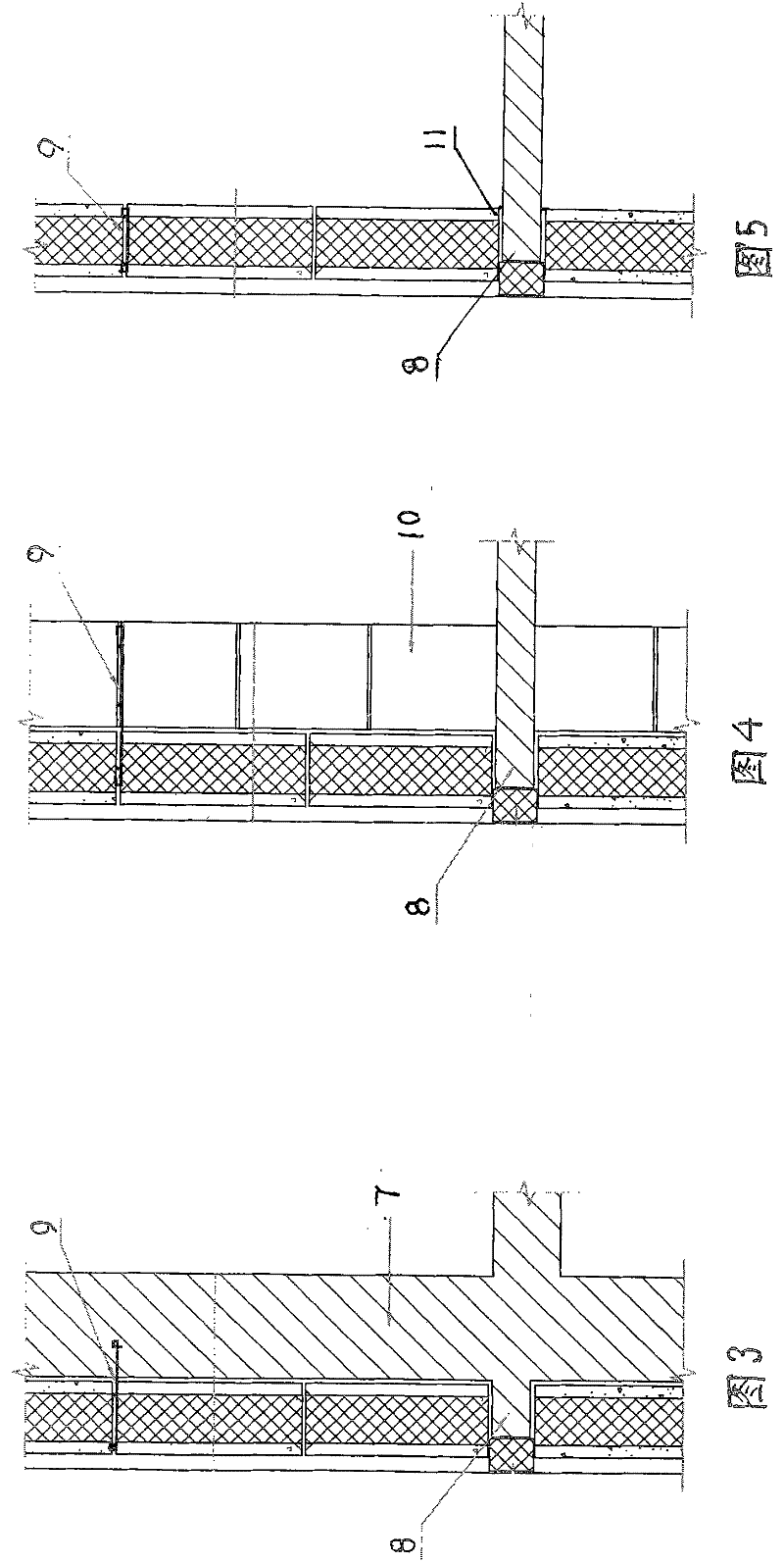

[0025] During the pre-laying construction in the shear wall formwork, when the formwork is poured to support the shear wall 7, the concrete support eaves 8 are made layer by layer when the shear wall is poured, and are attached to the outer formwork, and the heat-insulating and energy-saving blocks 1 are pre-built with mortar , the shear wall pouring formwork and the block 1 are tensioned by the tensioned steel bars 9 . The ends of the supporting eaves 8 are filled with polystyrene foam boards. After the masonry is completed, the steel bars are bound, and the formwork on the other side is supported to construct the main body of the shear wall. After completion, the heat-insulating and energy-saving blocks and the main body of the shear wall form a compact composite insulation wall structure, and the cement mortar is plastered and whitewashed.

Embodiment 3

[0027] During the external insulation construction of the building wall of the brick-concrete structure system, the concrete support eaves 8 are made when the brick-concrete structure is built, and the ends of the support eaves 8 are filled with polystyrene foam boards. On the support eaves 8, 24 brick wall load-bearing 600X300X120 heat-insulating and energy-saving blocks 1 are used as the form of external heat preservation. When building masonry, bricks and blocks are used to match the inside and outside of the support eaves 8. The height of the support eaves 8 and the tensioned steel bars 9 is 600mm , 24 brick walls 10 and blocks 1 are tensioned by tensioning steel bars 9 to form a composite masonry structure outside the blocks inside the bricks, which meets the load-bearing requirements and achieves the effect of heat preservation and energy saving, and is plastered with cement mortar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com