HAS composite plug removal technology

A process and technology of compound acid, which is applied in the direction of drilling composition, production fluid, wellbore/well parts, etc., can solve the problems of inconspicuous effect and short validity period, and achieve the elimination of inorganic pollution, long validity period, and improvement of effective penetration rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1. Simulating the actual formation temperature and pressure, passing the compound acid and the active agent successively through the natural core to carry out the plugging removal flow simulation test of the core, and judging the effect of plugging removal by the change of standard brine permeability before and after the injection of the compound plugging removal fluid.

[0037] η=(Kw-Kw 0 ) / Kw×100%

[0038] In the formula, η-permeability increase rate, %

[0039] k 0 - Annotate the initial hydraulic permeability of the core before liquid plugging, ×10 -3 μm 2 ;

[0040] Kw-the hydraulic permeability of the core after annotating liquid plugging, ×10 -3 μm 2 .

[0041] Core physical simulation experiment data Table 3

[0042]

[0043] The average increase rate of core permeability is 100.81%.

Embodiment 2

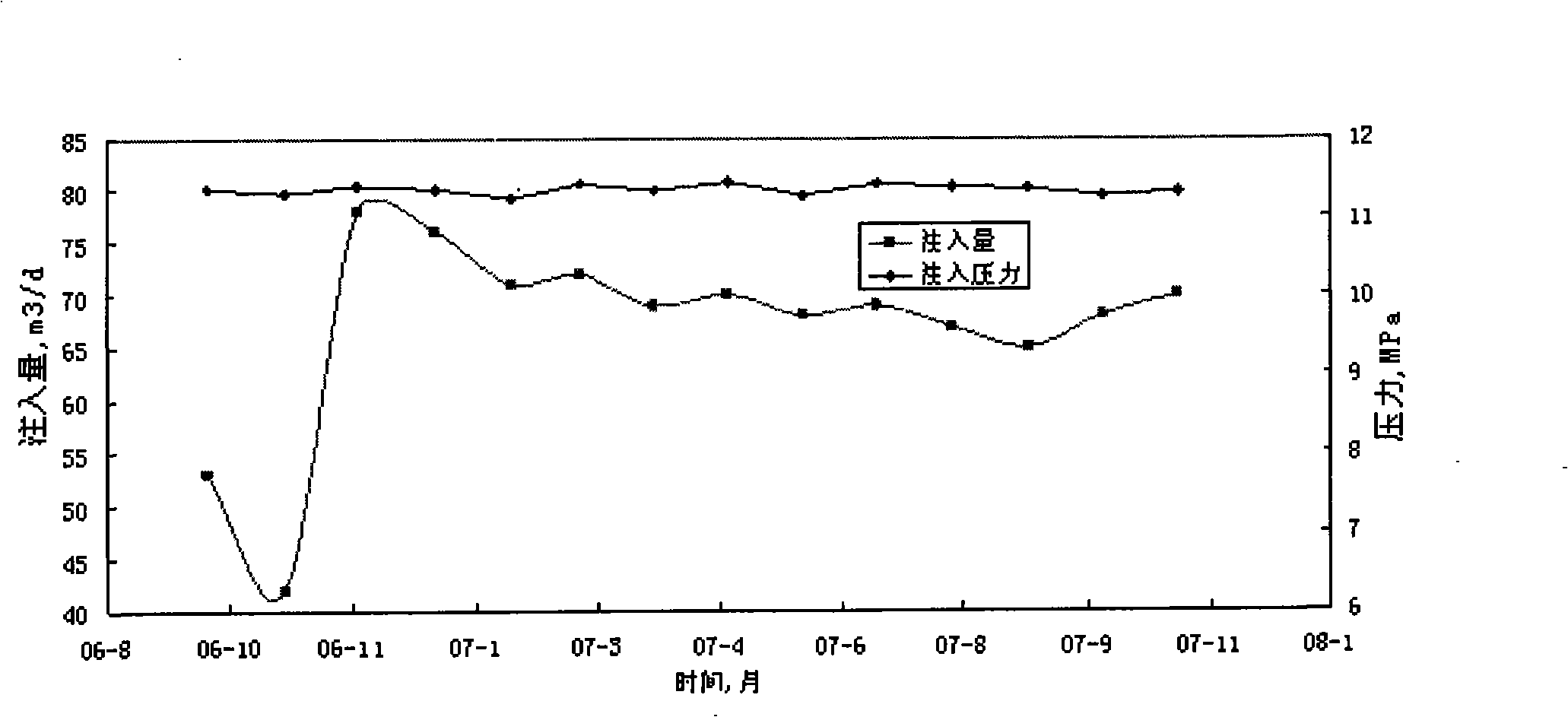

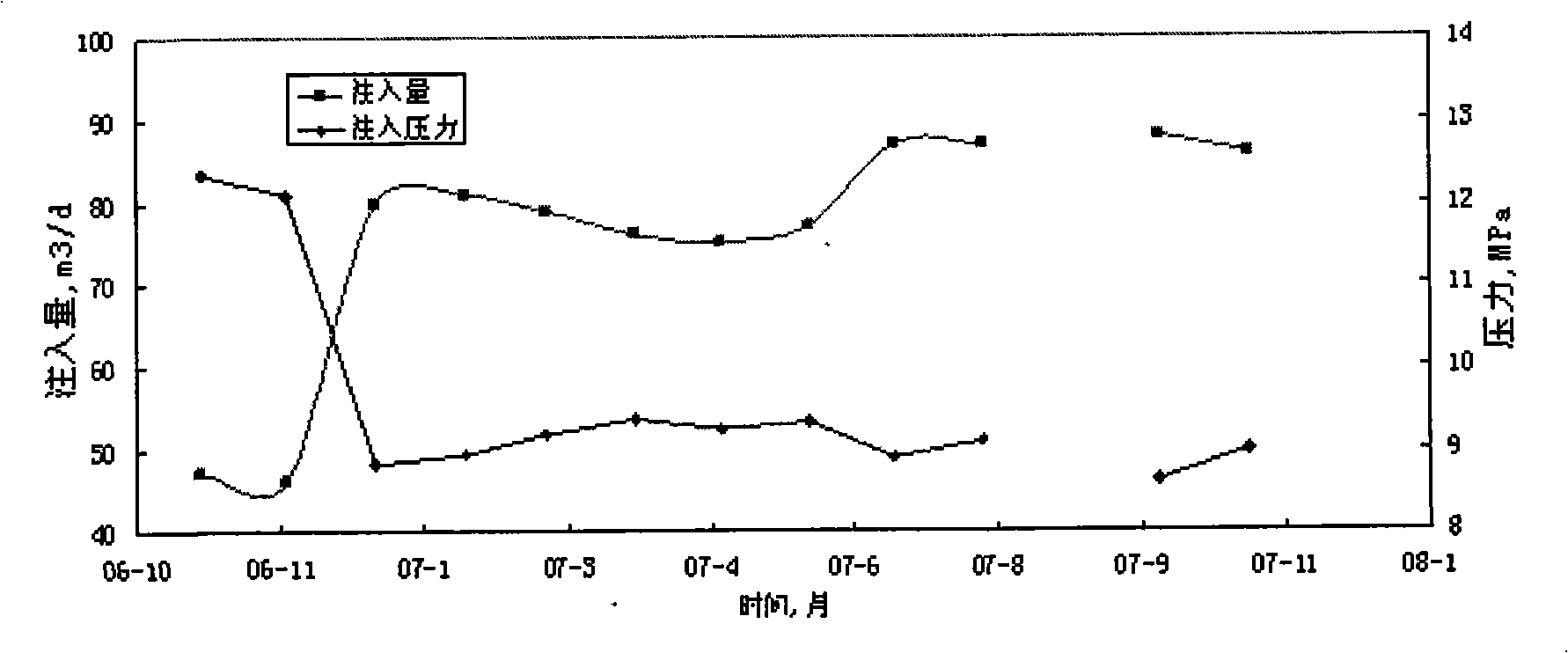

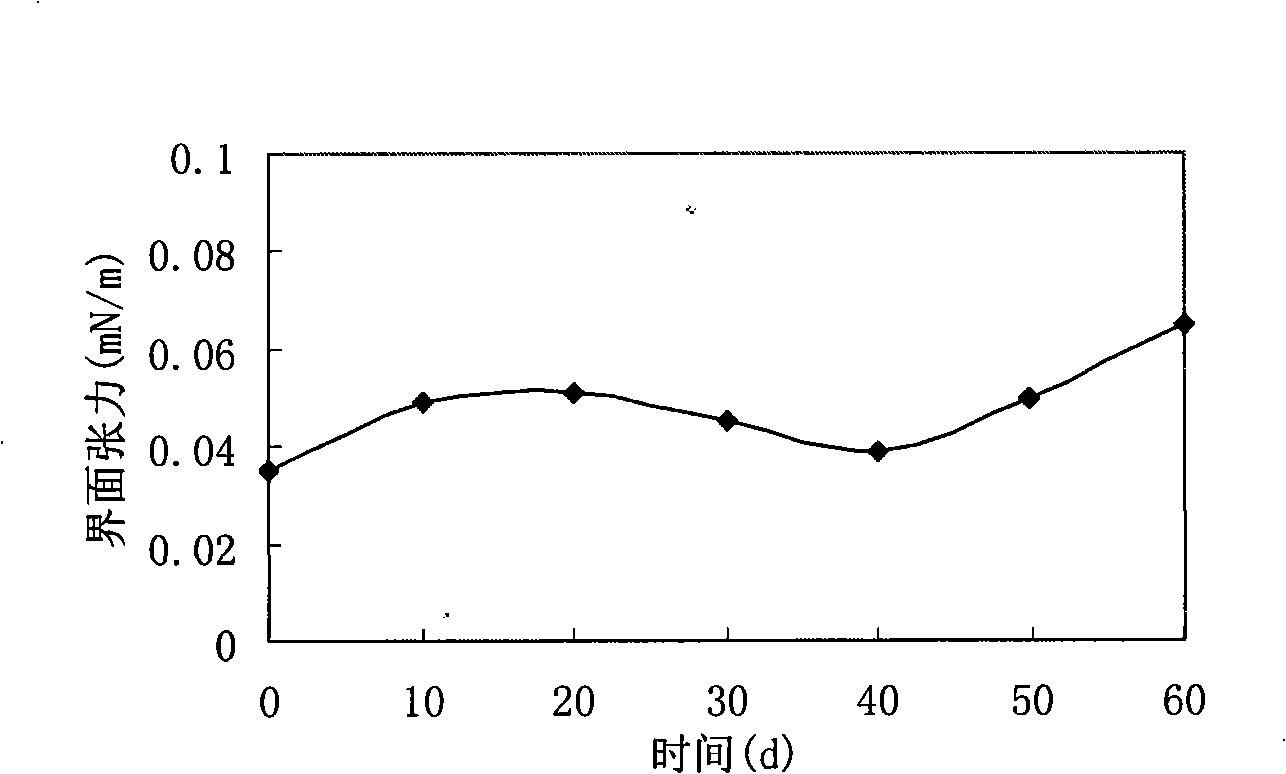

[0044] Example 2. Field test of tertiary infill wells in the west block of South 6 District:

[0045] 1. Geological characteristics of test wells and analysis of reasons for poor water absorption conditions

[0046] According to the actual injection status of the test well, through the analysis of the reservoir minerals and fluid physical properties in the tertiary infill well area of the west block of South 6 Block, combined with the logging results of the water absorption profile of the test well, the main reasons for the poor water absorption are as follows:

[0047] (1) The reservoir has poor homogeneity, uneven water absorption, serious conflicts between layers, and some layers do not absorb water;

[0048](2) The reservoir is a thin and dirty oil layer with poor fluidity, weak water absorption capacity, medium velocity sensitivity, medium strong water sensitivity, medium strong salt sensitivity, medium strong acid sensitivity, and medium strong alkali sensitivity. Conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com