Method for producing low polyxylose with dual-aqueous phase hydrolyzation system

A technology of xylooligosaccharide and hydrolysis system, which is applied in the direction of fermentation, etc., can solve the problems of difficult scale-up, low recycling rate of xylanase, and many process steps, so as to achieve high utilization rate, simplify the enzyme hydrolysis process, and simplify the process route effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: the preparation of xylanase

[0034] The xylanase used in the present invention is derived from recombinant Pichia pastoris NL-OU (Ouyang Jia, Wang Xiangming, Zhang Qing, Yan Ming, Xu Lin. Trichoderma reesei xylanase XYN II gene in Pichia pastoris Secreted expression. Forest Products Chemistry and Industry, 2007, 27(5): 83-88). The preparation method is as follows: After the recombinant Pichia pastoris NL-OU is activated on a plate, inoculate a single colony in a 50mL shake flask medium, and culture it at 30°C and 150r / min for 48 hours until the OD 600 Reach 2-6, obtain seed solution. Inoculate the seed solution with 10% (v / v) into sterilized glycerol medium, and ferment for about 20 hours at 28°C and 600r / min until the dissolved oxygen rises by more than 50%. Glycerol solution was fed into the tank at a flow rate of 20 mL / (L·h) for 12 hours, then stopped for 3 hours, the pH value was controlled at about 5.0, and the temperature was maintained at 28°C. Th...

Embodiment 2

[0035] Embodiment 2: the preparation of xylan

[0036] The corncobs are dried, crushed and sieved to obtain raw materials with particles of about 1 cm. At 25°C, sodium hydroxide and deionized water were added and stirred while adding. Then, cook at 90° C. for 3 hours. Filter to remove solids and collect cooking liquid. The cooking liquid is neutralized to pH5.0 with strong acid. The neutralized cooking liquid is desalinated by an ultrafiltration membrane with a molecular weight cut-off of 6000, and more than 90% of inorganic salts and low-molecular compounds are removed to obtain concentrated crude xylan liquid.

Embodiment 3

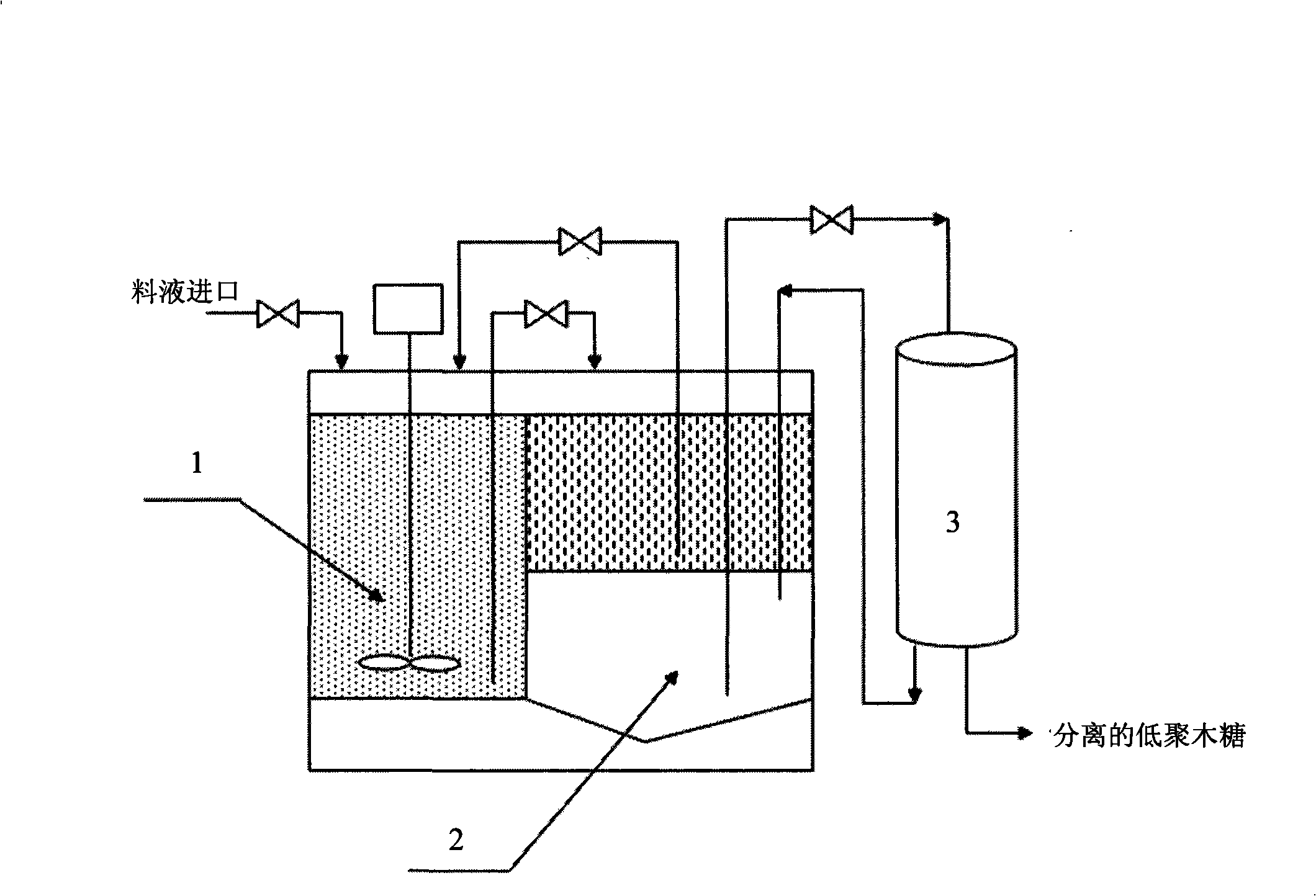

[0037] Example 3: Preparation of xylo-oligosaccharides by aqueous two-phase enzymatic hydrolysis

[0038] In the hydrolysis tank of the two-phase hydrolysis reactor, add concentrated crude xylan solution 200mL (xylan concentration is 20g / L), add 150g polyethylene glycol 2000 and 100g ammonium sulfate, add deionized water to total The system weight is 1000g. In the polyethylene glycol / ammonium sulfate system, the concentration of polyethylene glycol 2000 is 15% (w / w), and the concentration of ammonium sulfate is 10% (w / w). After mixing by mechanical stirring (150r / min), add 200IU xylanase crude enzyme solution for enzymatic hydrolysis. Under the conditions of pH 5.0, temperature 50° C., and stirring speed 150 r / min, the enzymatic hydrolysis reaction was carried out for 4 hours. Then, transfer the enzyme hydrolyzate to the distribution tank of the two-phase hydrolysis reactor, and let it stand for 60 minutes to complete the phase formation. The lower aqueous solution phase us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com