Method for measuring nickel content in smoke tipping paper

A technique for cigarette tipping paper and a measuring method, which is applied in the field of physical and chemical inspection of cigarette tipping paper, and can solve the problem that the nickel of cigarette tipping paper samples cannot be truly reflected, the acid-rushing conditions, the unsuitable measurement conditions, and the inconsistency of parallel results. Ideal and other problems, to achieve the effect of low blank value, fast and simple acid removal process, and less reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0060] 1. Instruments and reagents: plastic volumetric flask, 50mL. Analytical balance, the sensitivity is 0.0001g. Teflon beaker, 100mL. Airtight microwave digestion instrument (with microwave digestion tank). Temperature controlled electric heater. Graphite Furnace Atomic Absorption Spectrometer. Water, ultrapure water or double distilled water of equivalent purity. Nitric acid, 65%. Nitric acid, 1%. Hydrogen peroxide, 30%. Hydrochloric acid, 37%. Hydrofluoric acid, 40%. Nickel standard stock solution, concentration 10.0mg / L.

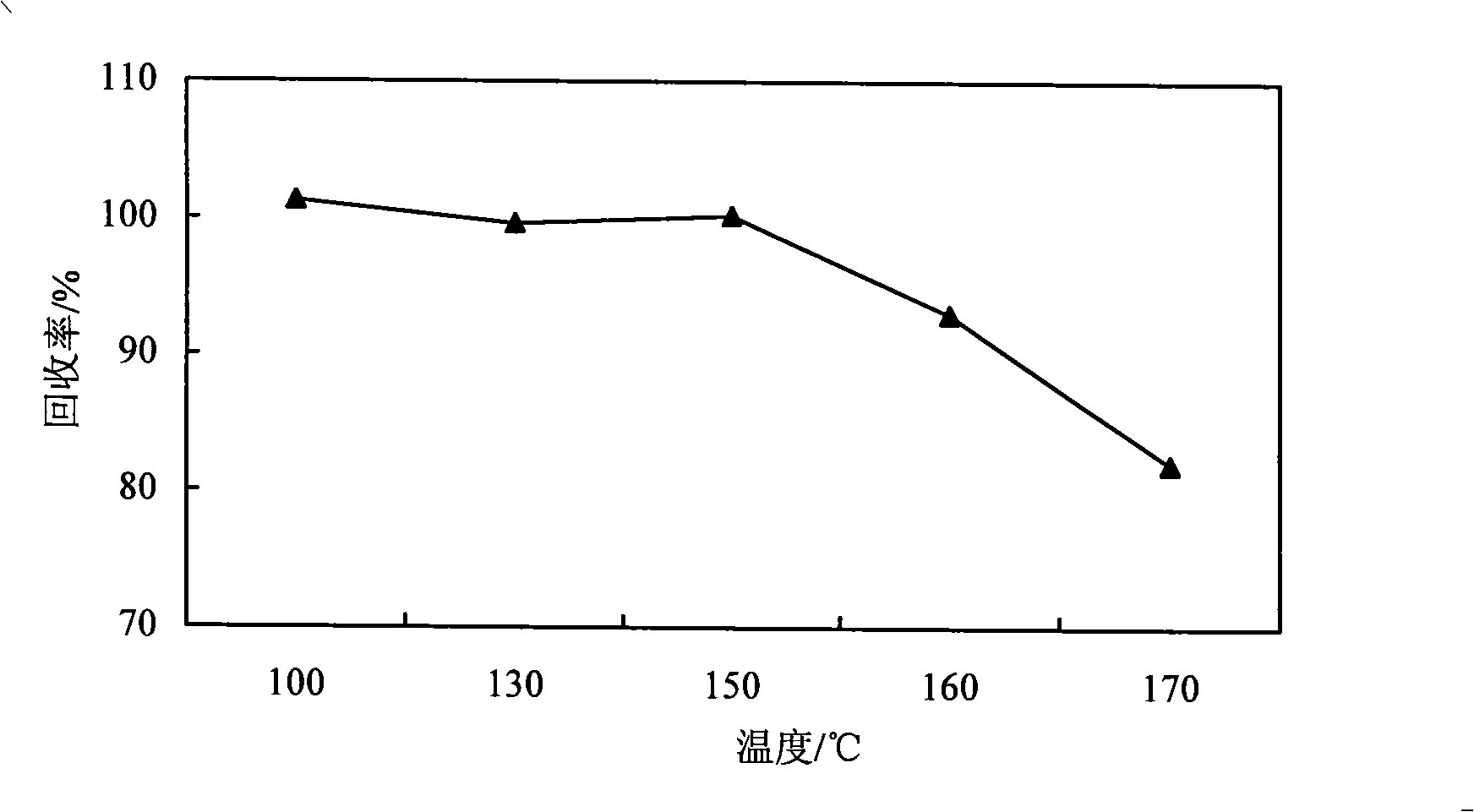

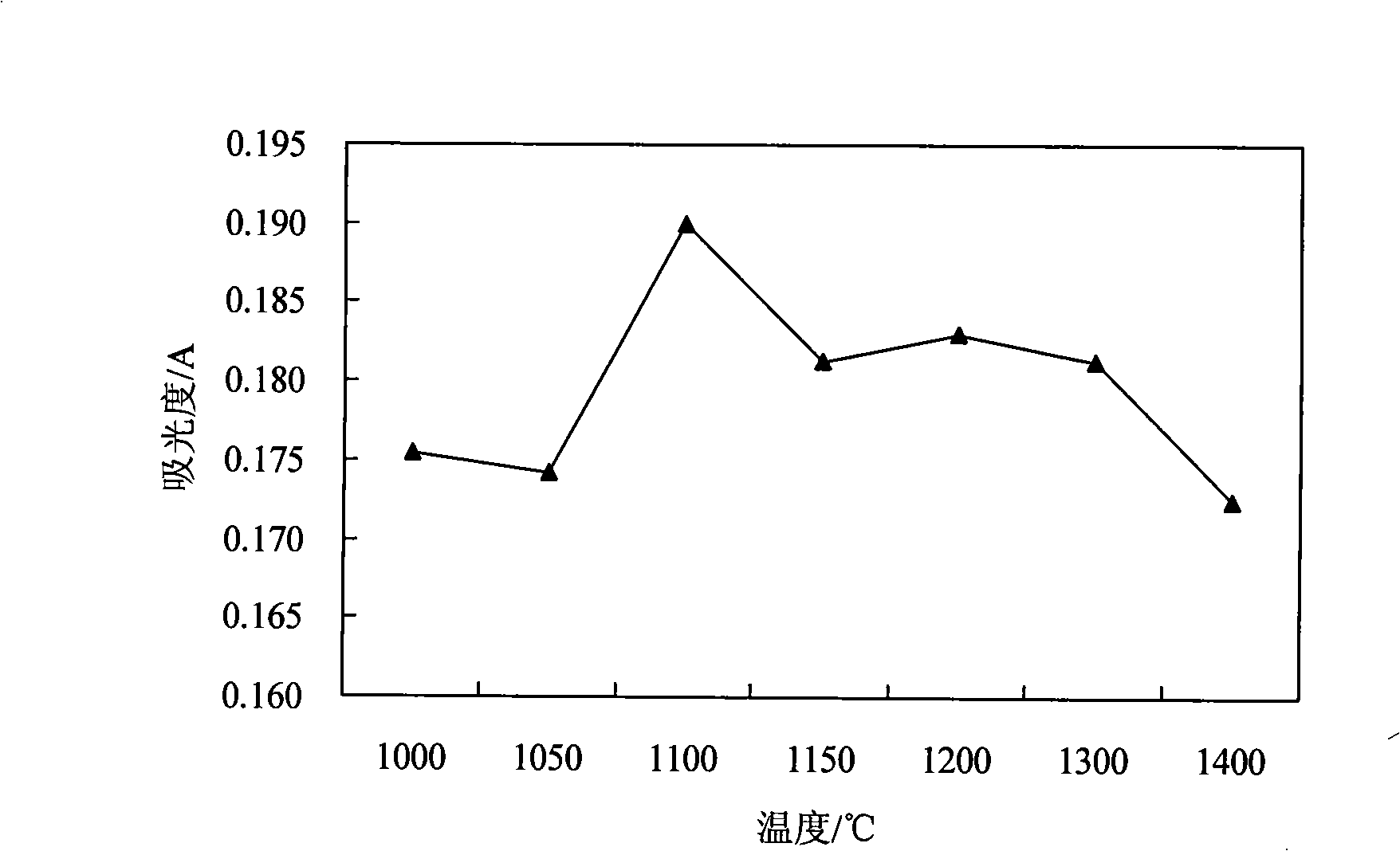

[0061] 2. Sample treatment: Precisely weigh 0.2g tipping paper sample A, place it in a microwave digestion tank, add a certain volume of 65% nitric acid, 40% hydrofluoric acid, 37% hydrochloric acid and 30% After the hydrogen peroxide is sealed, put it into a microwave digestion apparatus, and carry out microwave digestion according to the digestion program shown in Table 2. After the digestion is completed, take out the digestion tank afte...

example 2

[0064] As described in Example 1, the tipping paper sample whose grade was selected was B, and the nickel in the sample was measured to be 1.67 mg / kg.

example 3

[0066] As described in Example 1, the tipping paper sample whose grade was selected was C, and the nickel in the sample was measured to be 1.51 mg / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com