Cationic surface sizing agent and base paper for newspaper

A surface sizing agent, cationic technology, applied in the direction of papermaking, paper coating, water repellent addition, etc., can solve the problem of reduced effect of anionic surface sizing agent, achieve good washability, difficult to feel fat pollution 、Excellent effect of resistance to plate pollution and adaptability

Active Publication Date: 2008-10-29

HARIMA CHEM INC

View PDF9 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to such a situation, the effect of the conventional anionic surface sizing agent is reduced, so especially in the case of neutral paper, a cationic surface sizing agent is applied

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-1

Embodiment 1-2

Embodiment 1-3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

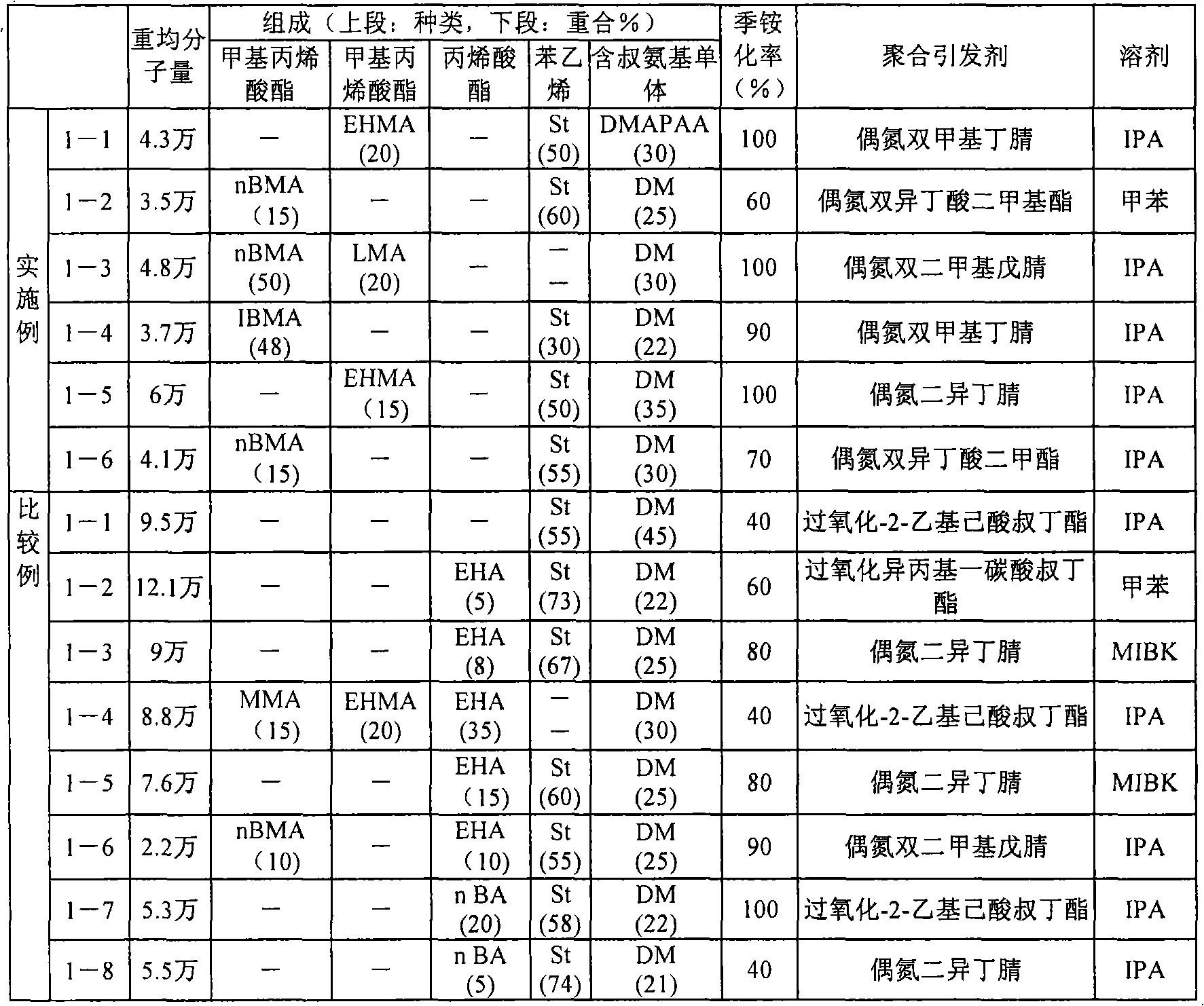

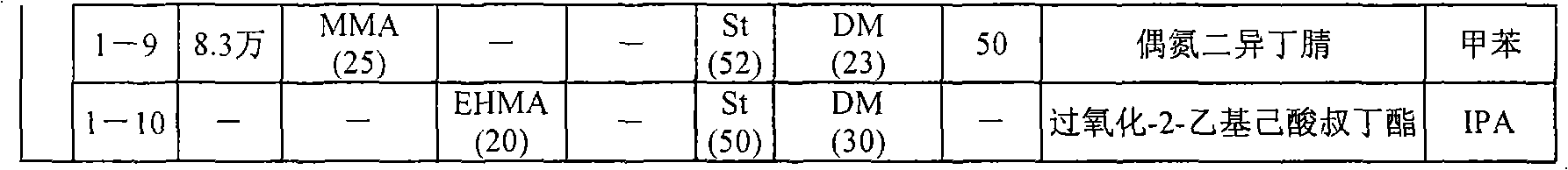

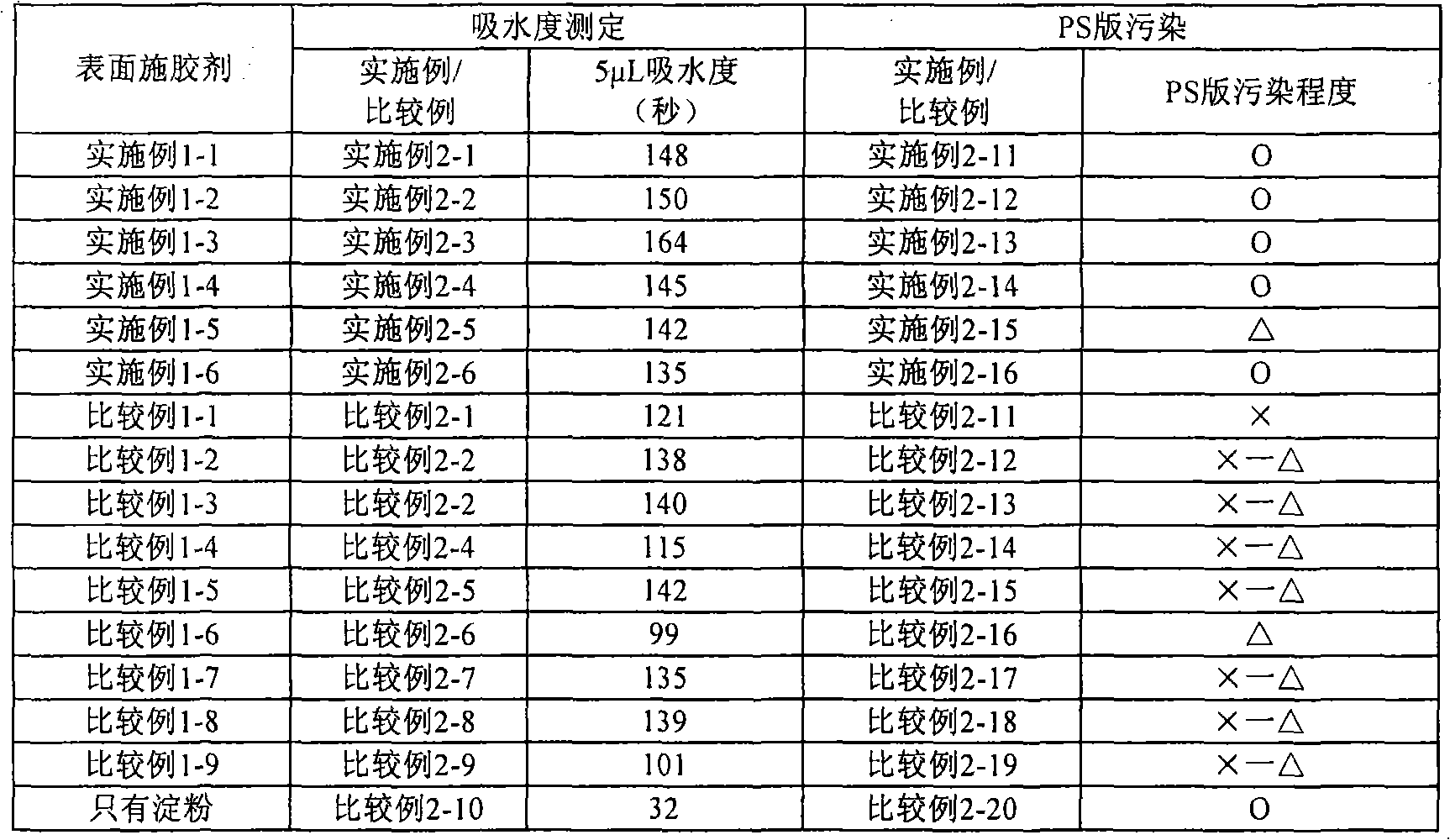

Disclosed is a cationic surface sizing agent intended to be coated on a base paper for a newspaper, which can improve a sizing property and scumming resistance during offset printing. The cationic surface sizing agent is produced by quaternizing a copolymer having a weight average molecular weight of 30,000 to 60,000, wherein the copolymer is produced by polymerizing (a) 20 to 40% by weight of a monomer having a tertiary amino group, (b) 10 to 80% by weight of a C4-C18 alkyl ester of (meth)acrylic acid and (c) 0 to 70% by weight of styrene or a derivative thereof with an azo-type polymerization initiator in the presence of a chain transfer agent. The cationic surface sizing agent has an improved sizing property without causing the decrease in the level of hydrophobicity of the copolymer and can prevent the sensitization of a plate to be printed (e.g., a PS plate) by specifying the composition of the monomers, using an azo-type polymerization initiator and also specifying the molecularweight of the copolymer.

Description

technical field The present invention relates to a cationic sizing agent having both sizing properties and plate contamination resistance adaptability in offset printing. Background technique In the offset printing of newsprint, the improvement of the quality of the paper proposed in response to the recent demand for high-speed and multi-color printing, the environmental response of the offset ink proposed in consideration of the environment during printing, and the printing process The conversion of dampening alkaline etching solution to fresh water or the reduction of dampening solution, etc. On the other hand, since newsprint requires ultra-light weight, neutralization, high-speed printing, and high quality, it needs further high water resistance. Therefore, when making base paper, not only internal sizing agent but also surface sizing agent and For starches, apply on machine. Especially recently, in order to improve the workability during papermaking, or to reduce th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D21H19/20D21H21/16

CPCC08F220/34D21H17/37D21H19/20D21H17/455D21H21/14C08F212/08C08F220/18D21H17/35D21H21/16C08F220/1804C08F220/1812Y10T428/3179

Inventor 稻冈和茂中田智彦桥口芳春

Owner HARIMA CHEM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com