Method for absorbing CO2 of stack gas by ammonia water

A flue gas and CO2 technology, applied in separation methods, chemical instruments and methods, air quality improvement, etc., can solve the problems of secondary pollution, large amount of ammonia, small gas resistance drop and removal efficiency, etc., to reduce carbon dioxide Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

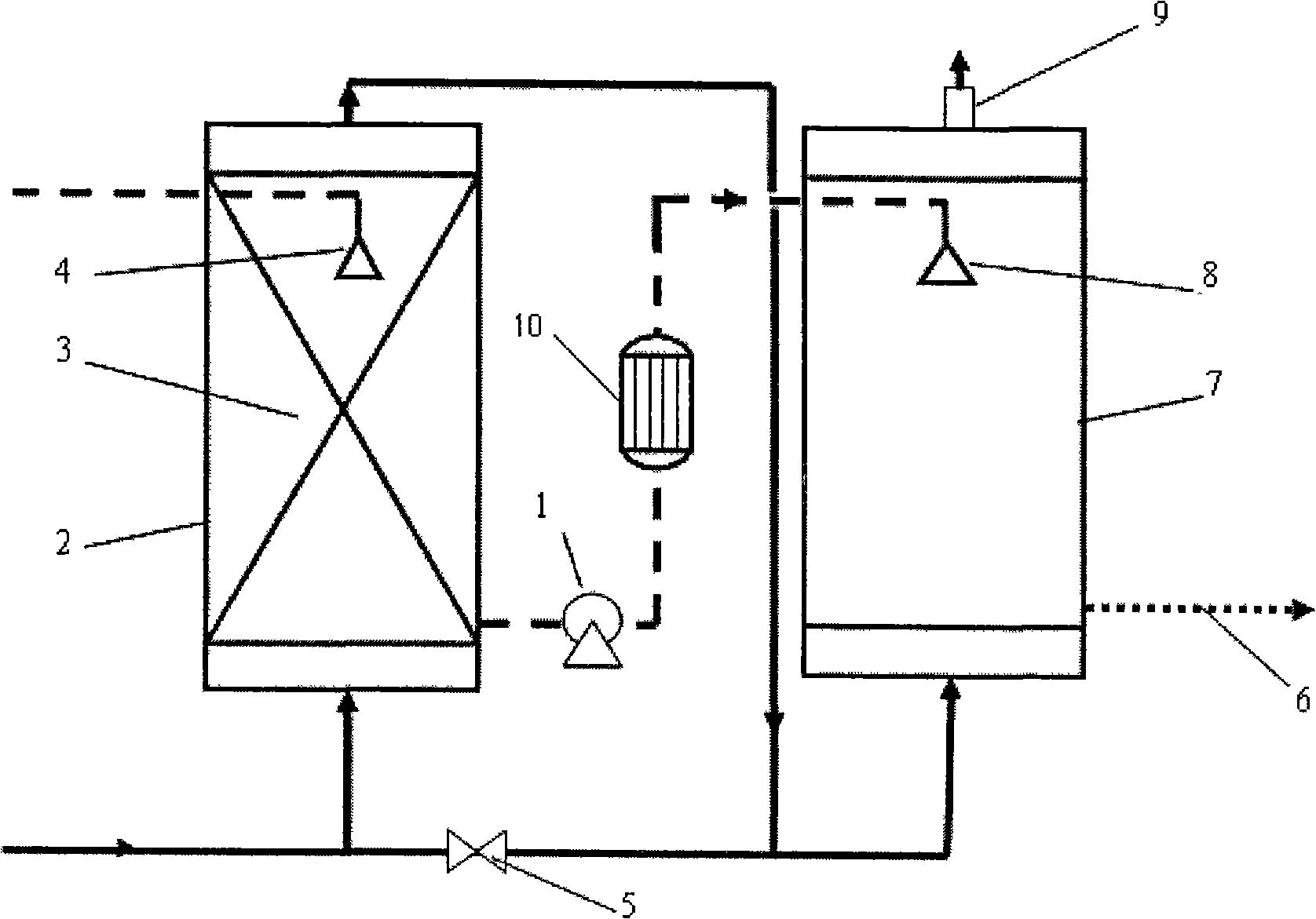

[0044] as attached figure 1 , a method of absorbing CO2 in flue gas with ammonia water:

[0045] ① will be used by industry O 2 , N 2 , CO 2 According to the flue gas composition of the power plant, 3% O in the volume ratio of each component 2 , 84% N 2 , 13% CO 2 The mixed flue gas is first pressurized to 0.4-0.6 MPa by a gas compressor, and then sent to the primary ammonia water spray tower 2 from the bottom. According to the absorption effect, part of the flue gas directly enters the secondary ammonium carbonate spray tower 7 by opening the intake control valve 5 .

[0046] ②Ammonia water with a concentration of 15% is sprayed from the top of the primary ammonia water spray tower 2 through the ammonia water sprayer 4, so that the ammonia water sprayed above and the flue gas are fully contacted to make the gas-liquid two-phase contact reaction.

[0047] ③ Control the reaction temperature in the primary ammonia water spray tower 2 to 35°C, and the reaction products are a...

Embodiment 2

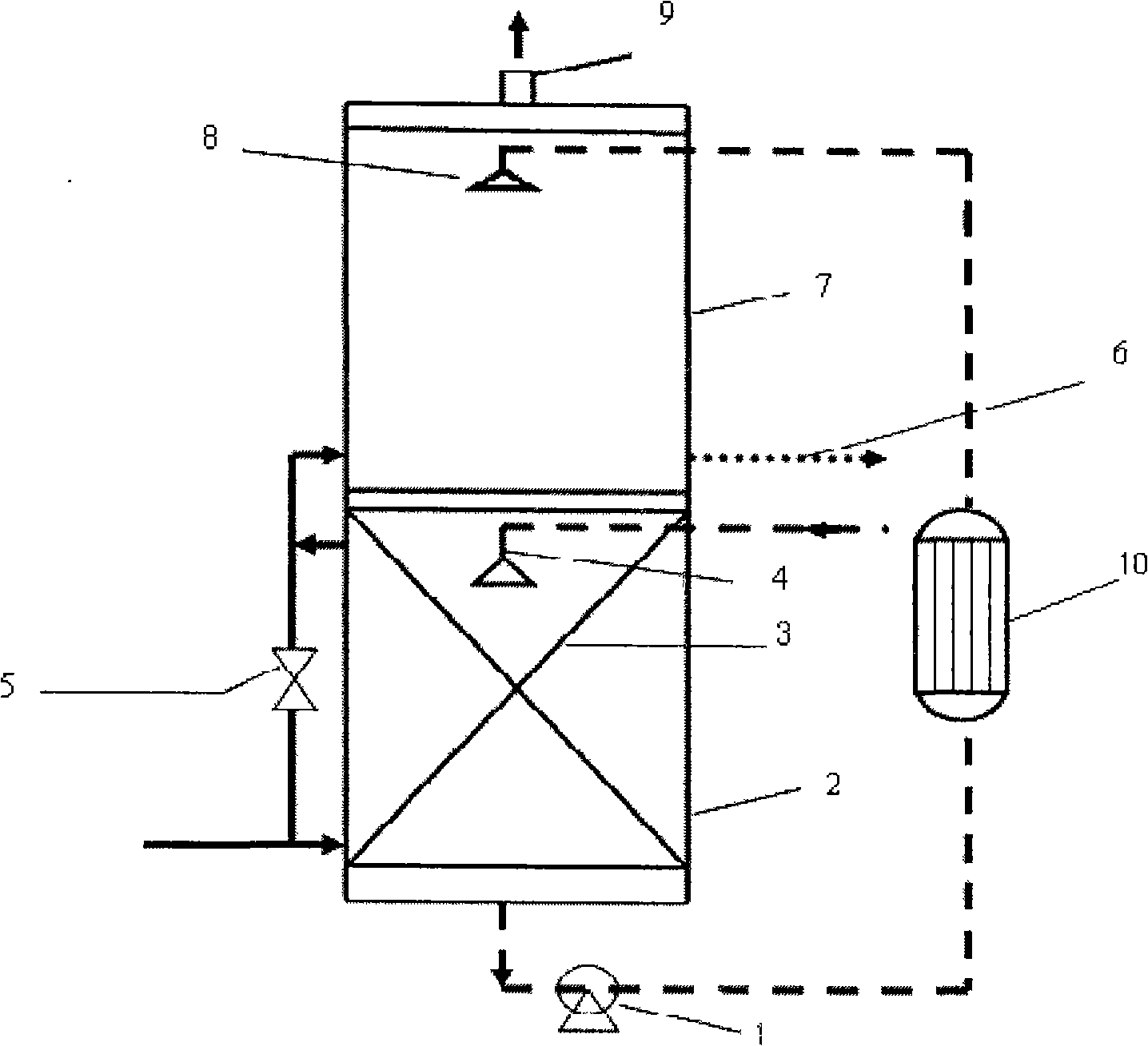

[0052] as attached figure 2 , a process for removing high-concentration carbon dioxide in flue gas:

[0053] ① will be used by industry O 2 , N 2 , CO 2 Prepare the simulated flue gas with the content of each component as follows: 3% O 2 , 47% N 2 , 50% CO 2 . The simulated flue gas is fed into the primary ammonia spray tower 2 from the bottom through the intake device. According to the absorption effect, part of the flue gas directly enters the secondary ammonium carbonate spray tower 7 by opening the intake control valve 5 .

[0054] ② Spray ammonia water with a concentration of 15.0% from the top of the first-stage spray tower 2 through the ammonia water sprayer 4 to make the gas-liquid two-phase contact reaction, so that the flue gas fully contacts with the ammonia water sprayed above.

[0055] ③ Control the reaction temperature in the primary ammonia water spray tower 2 to 35° C., and the reaction products are ammonium carbonate and ammonium carbamate solutions. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com