Coordination polymer molecular aggregate catalyst material containing metalloporphyrin and preparation thereof

A technology of coordination polymers and molecular aggregates, applied in the field of molecular materials and chemical catalysis, can solve the problems of difficult separation of catalysts and reactants/products, complicated preparation process, and difficult product separation, and achieve simple components and structures. The design and regulation, low production environment requirements, and simple and easy preparation technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

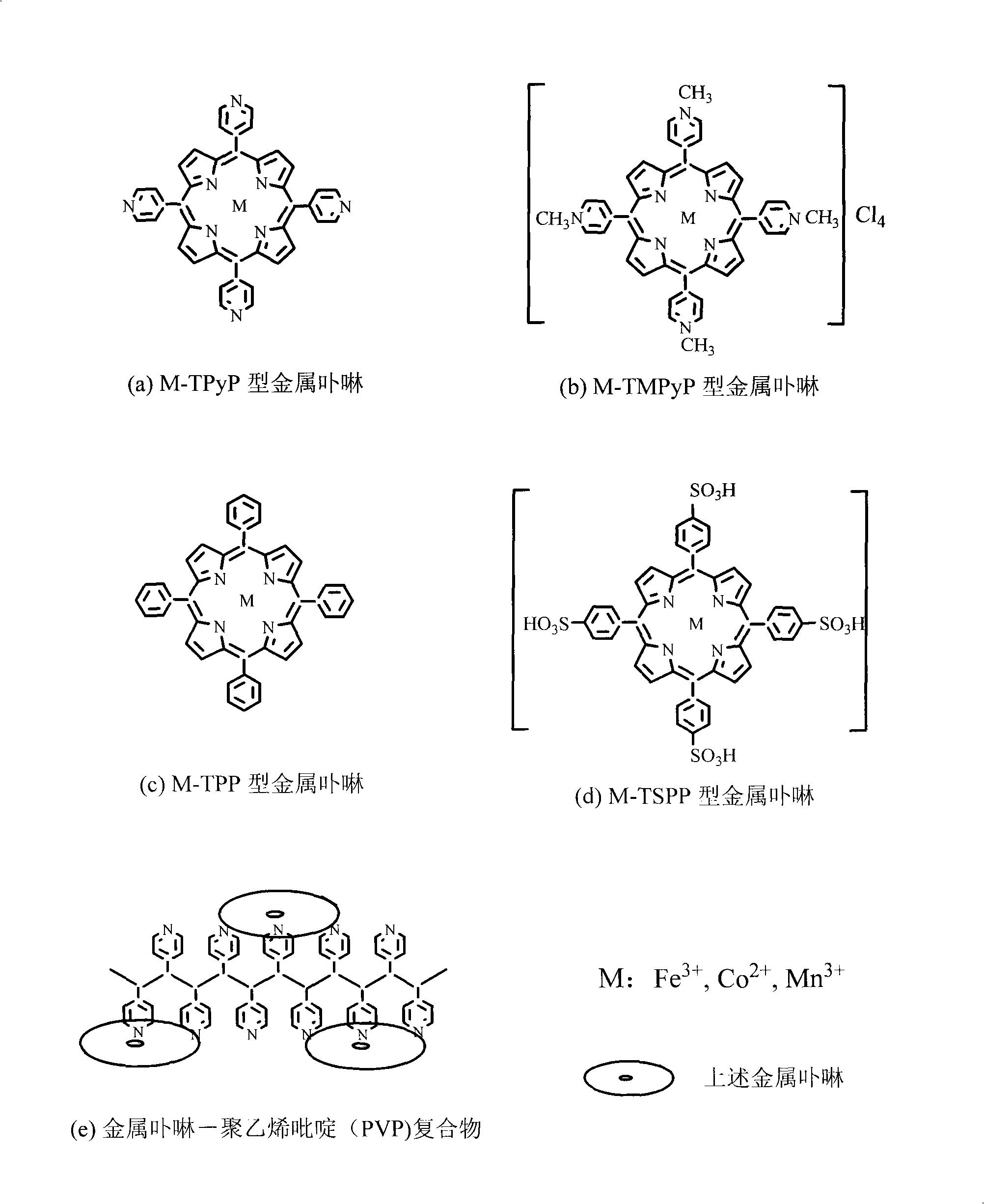

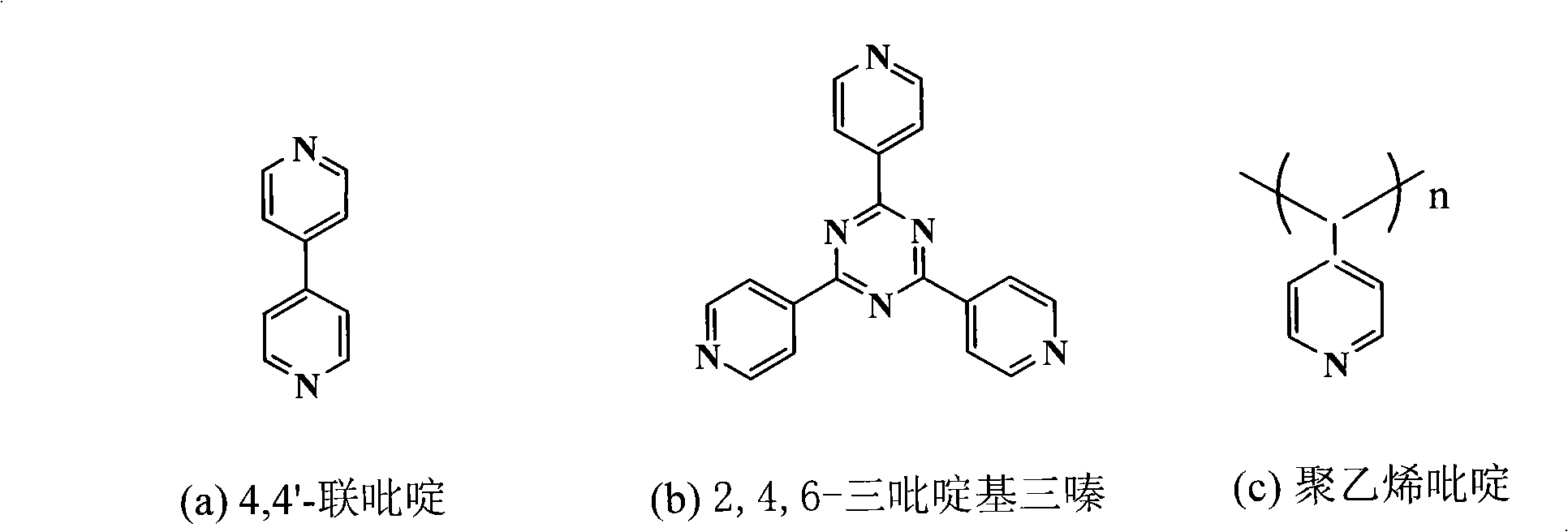

Method used

Image

Examples

Embodiment 1

[0028] Add 0.05 mol / L CdCl to the cleaned Langmuir tank 2 aqueous solution, and then dropwise add about 100 microliters of 0.3 mmol / liter chloroform solution of metal Mn porphyrin at the gas-liquid interface with a syringe. After the chloroform solvent is completely volatilized and the interface coordination reaction is completed (usually takes more than 20 minutes), compress the surface until the surface pressure rises to about 20mN / m. Keeping the surface pressure, a multilayer film of Cd-MnTPyP, a molecular aggregate material containing metalloporphyrin, is deposited on the surface of a clean quartz substrate by using LB film extraction technology.

Embodiment 2

[0030] Add K containing 0.1 mmol / L to the cleaned Langmuir tank 2 PdCl 4 Aqueous solution, then drop about 100 microliters of 0.3 mmol / liter metal Mn porphyrin / PVP complex chloroform solution at the gas-liquid interface with a syringe. After the chloroform solvent is completely volatilized and the interface coordination reaction is completed (usually takes more than 20 minutes), compress the surface until the surface pressure rises to about 20mN / m. Keeping the surface pressure, a multilayer film of PdMnTPyP / PVP, a molecular aggregate material containing metalloporphyrin, is deposited on the surface of a clean quartz substrate by using LB film extraction technology.

Embodiment 3

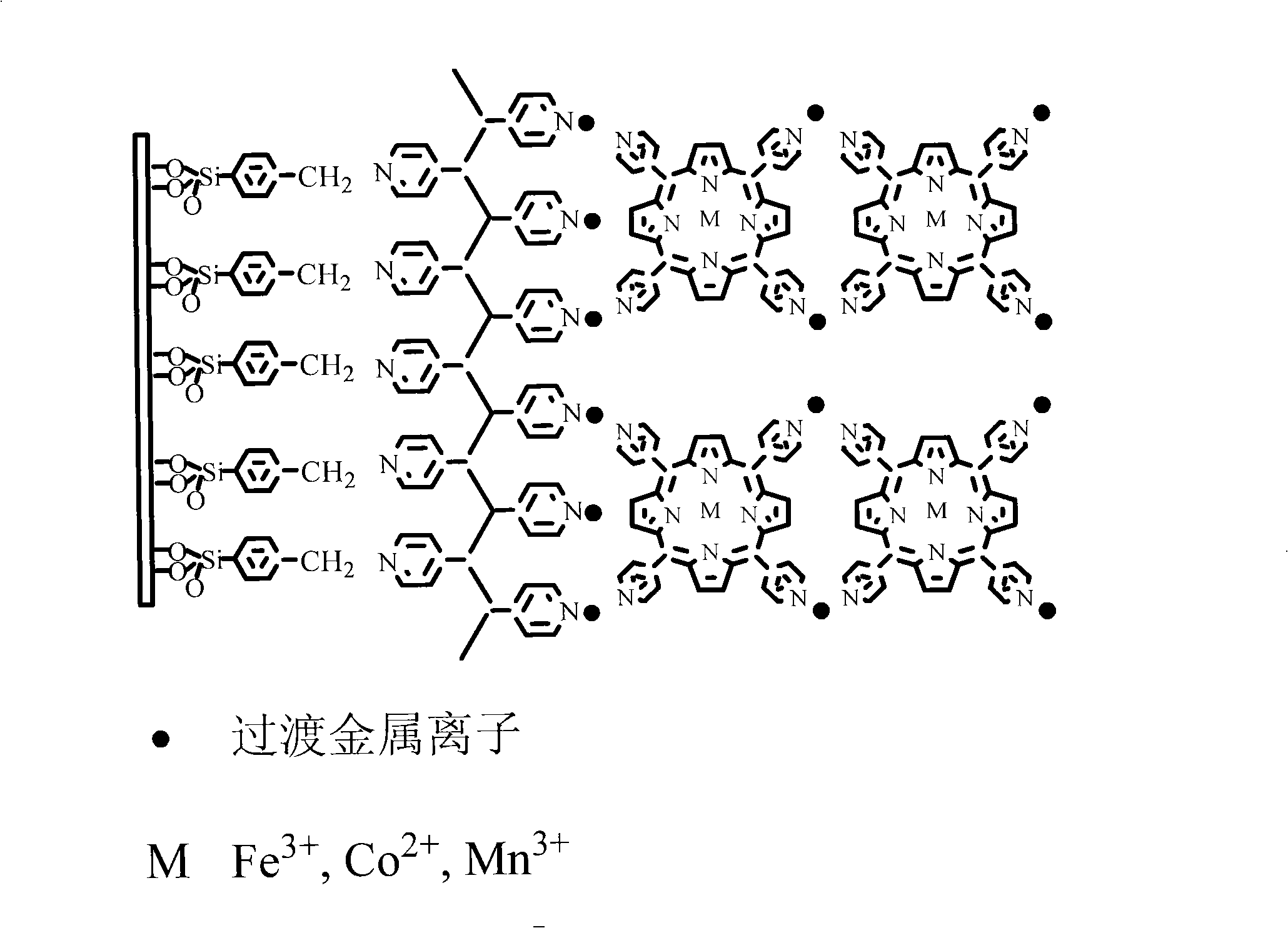

[0032] The solid (glass, quartz, mica or conductive porphyrin) substrate that has been cleaned and treated hydrophilically with 4% sodium hydroxide is first reacted with 2% bromobenzylsilane in chloroform or methanol solution to form an active bromobenzene The solid substrate modified by silane monolayer film is then reacted with 5% polyvinylpyridine to form a monolayer film covered by polyvinylpyridine on the solid surface. Again, by mixing with 0.1 mol / L CdCl 2 or 0.3 mmol / L K 2 PdCl 4 Coordination reaction is carried out, a layer of transition metal ion layer is combined on the surface of polyvinylpyridine, and it reacts with metallo-Fe porphyrin containing 2 mmol / L tetrapyridyl to form a metallo-porphyrin molecular layer. Finally, the above-mentioned coordination of metal ions and tetrapyridyl metalloporphyrin is repeated to form a Cd-FeTPyP or Pd-FeTPyP molecular aggregate material directly grafted on the surface of the solid substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com