Nanocapsule phase-change material for cold storage and preparation thereof

A nanocapsule and phase change cold storage technology, which is applied in the direction of microcapsule preparation, microsphere preparation, heat exchange materials, etc., can solve the problems of low cold storage temperature and low cold storage density, achieve enhanced heat transfer capacity, reduce preparation cost, The effect of improving coating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

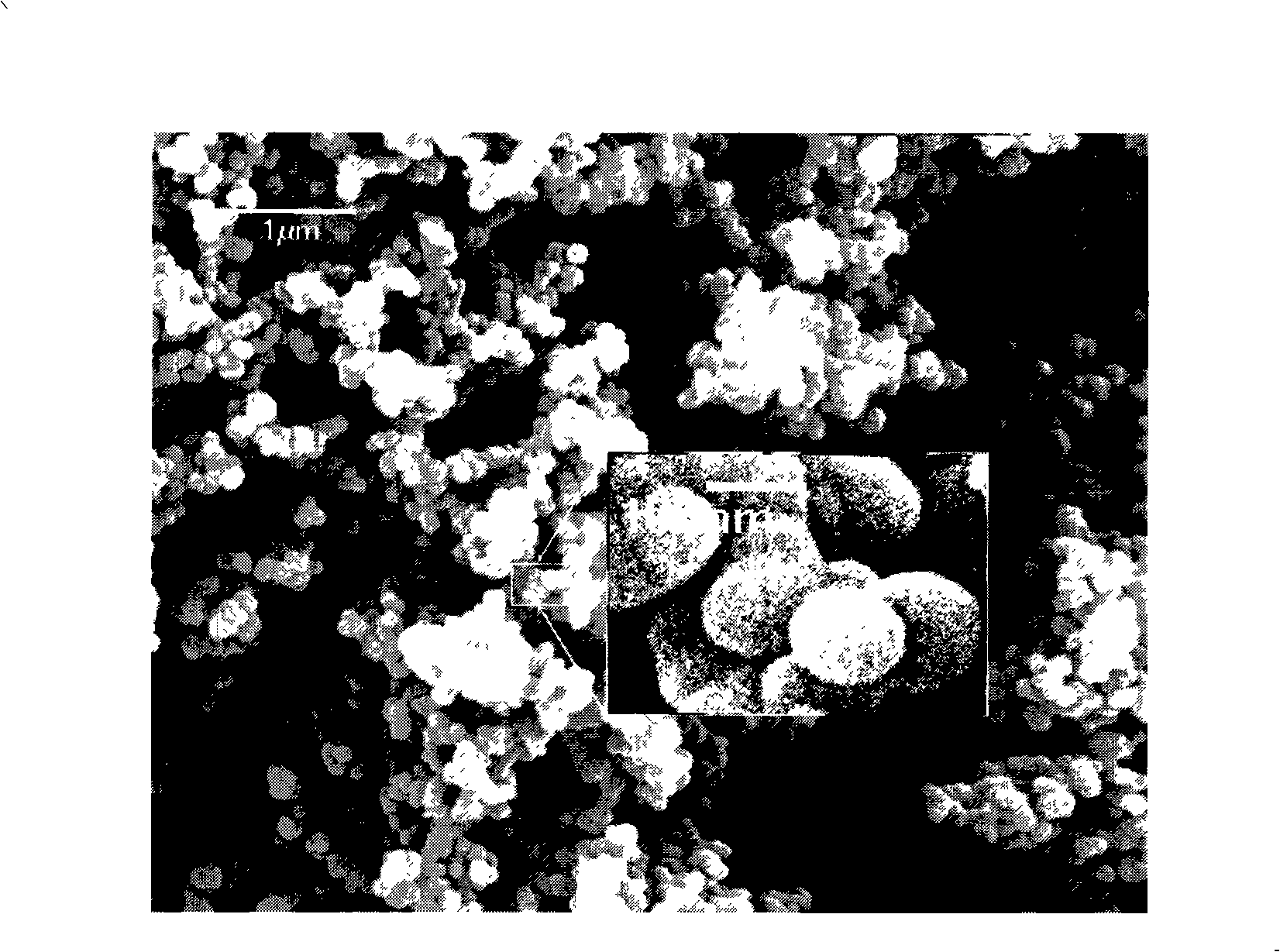

Image

Examples

Embodiment 1

[0025] A nanocapsule phase-change cold storage material according to the present invention comprises a core material and a capsule wall material, the core material is the capsule core material, the capsule wall wall material is the capsule wall, and the capsule core made of the phase-change cold storage material The substance is coated in the capsule wall made of urea-formaldehyde resin. The capsule core and the capsule wall are formed in a mass ratio of 5:3.

[0026] A preparation method of the above-mentioned nanocapsules, comprising the following steps:

[0027] (1) Prepolymer preparation: Add 2 g of urea and 12 g of formaldehyde into a conical flask, add 20 mL of deionized water to dilute, and adjust the pH value to 7-8 with triethanolamine after the urea is completely dissolved. The reaction was heated and stirred with a magnetic stirrer for 1 hour, the temperature was controlled at 70° C., and the rotational speed was controlled at 200 rpm. After completion, add 20mL h...

Embodiment 2

[0032] Another nanocapsule phase-change cold storage material according to the present invention includes a capsule core and a capsule wall, and the capsule core made of phase-change cold storage material is covered in the capsule wall made of urea-formaldehyde resin. The capsule core and the capsule wall are formed in a mass ratio of 5:2.

[0033] A preparation method of the above-mentioned nanocapsules, comprising the following steps:

[0034] (1) Preparation of prepolymer: Add 3 g of urea and 14 g of formaldehyde into a conical flask, add 20 mL of deionized water for dilution, and adjust the pH value to 7-8 with triethanolamine after the urea is completely dissolved. The reaction was heated and stirred with a magnetic stirrer for 1 hour, the temperature was controlled at 60° C., and the rotational speed was controlled at 200 rpm. After completion, add 20mL hot water to dilute.

[0035] (2) Emulsion preparation: Add 0.8g of sodium lauryl sulfate emulsifier, 2g of resorcino...

Embodiment 3

[0039]Another nanocapsule phase-change cold storage material according to the present invention includes a capsule core and a capsule wall, and the capsule core made of phase-change cold storage material is covered in the capsule wall made of urea-formaldehyde resin. The capsule core and the capsule wall are formed in a mass ratio of 10:3.

[0040] A preparation method of the above-mentioned nanocapsules, comprising the following steps:

[0041] (1) Preparation of prepolymer: Add 3 g of urea and 16 g of formaldehyde into a conical flask, add 20 mL of deionized water to dilute, and adjust the pH value to 7-8 with triethanolamine after the urea is completely dissolved. The reaction was heated and stirred with a magnetic stirrer for 1 hour, the temperature was controlled at 80° C., and the rotational speed was controlled at 200 rpm. After completion, add 20 mL of hot water to dilute.

[0042] (2) Emulsion preparation: Add 1g of sodium lauryl sulfate emulsifier, 3g of resorcinol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com