Method for preparing electrochemical anodic oxidation of large pipe diameter TiO2 nanometer tube

A technology of anodizing and large diameter, which is applied in the field of surface treatment for expanding the diameter of TiO2 nanotubes, and achieves the effects of less process parameters, less environmental damage and easy adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

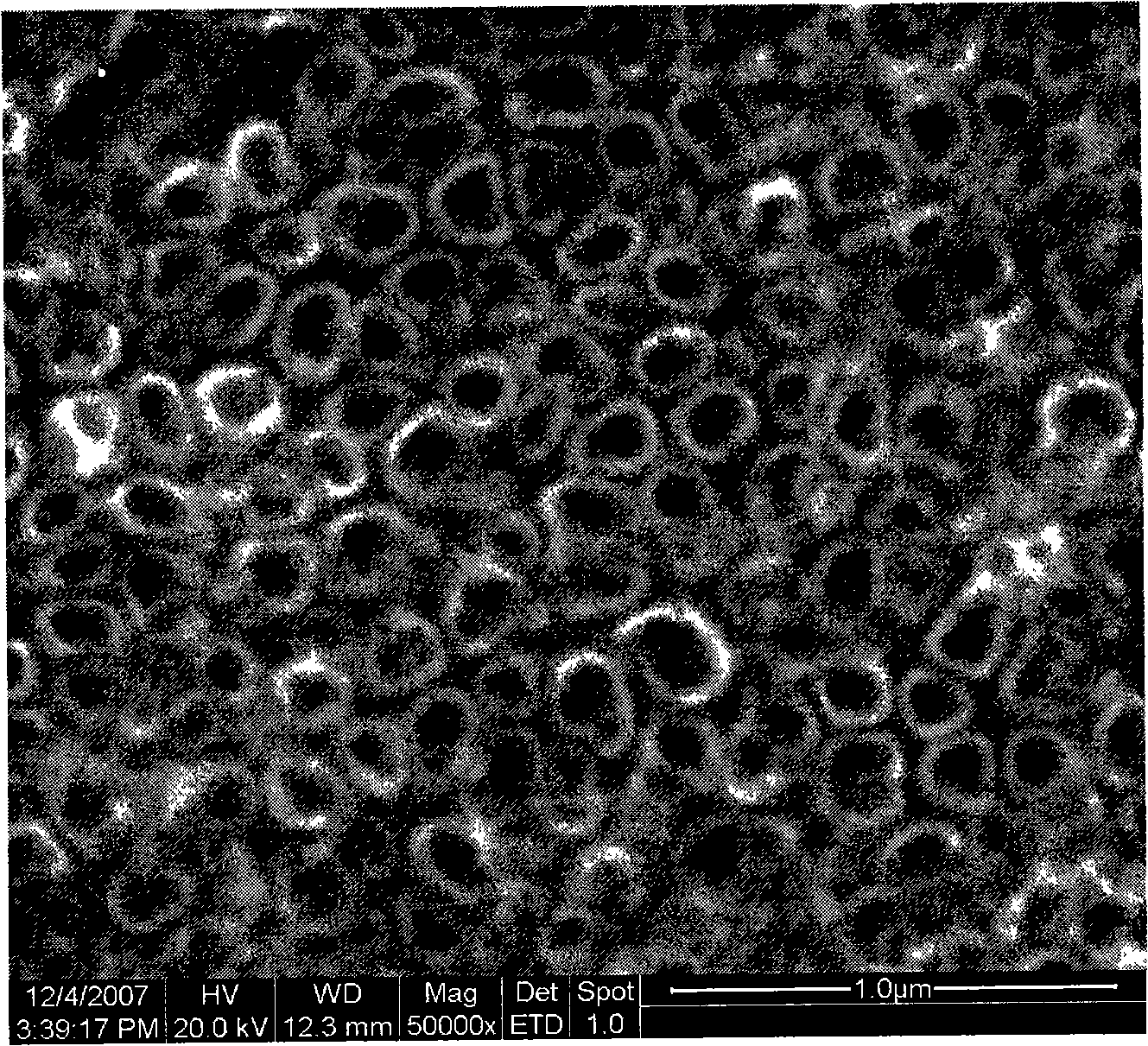

[0020] Embodiment 1, with the technical pure titanium after cleaning, pickling, drying: place the anode of electrochemical anodic oxidation reaction, take graphite as counter electrode; In hydrofluoric acid water system, add phosphoric acid as activator (partition The ratio is 0.15mol / LHF-0.5mol / LH 3 PO 4 ), and were oxidized twice under the voltage conditions of 20V and 25V respectively. Each oxidation time is 1 hour. After oxidation, the samples were removed and stored dry. Observe the surface morphology of the sample by SEM: the nanotubes are arranged in an orderly and compact manner, the nanotubes have a complete shape, the maximum diameter of the nanotubes is about 220nm, and the average diameter of the nanotubes is about 200nm.

Embodiment 2

[0021] Embodiment 2, with the commercially pure titanium after cleaning, pickling, drying: place the anode of electrochemical anodic oxidation reaction, take graphite as counter electrode; In hydrofluoric acid water system, add phosphoric acid as activator (partition The ratio is 0.15mol / LHF-1mol / LH 3 PO 4 ), and were oxidized twice under the voltage conditions of 20V and 25V respectively. Each oxidation time is 1 hour. After oxidation, the samples were removed and stored dry. Observe the surface morphology of the sample by SEM: the nanotubes are arranged in an orderly and compact manner, the nanotubes have a complete shape, the maximum diameter of the nanotubes is about 220nm, and the average diameter of the nanotubes is about 200nm.

Embodiment 3

[0022] Embodiment 3, with the industrial pure titanium after cleaning, pickling, drying: place the anode of electrochemical anodic oxidation reaction, take graphite as counter electrode; In hydrofluoric acid water system, add phosphoric acid as activator (partition The ratio is 0.15mol / LHF-2mol / LH 3 PO 4 ), and were oxidized twice under the voltage conditions of 20V and 25V respectively. Each oxidation time is 1 hour. After oxidation, the samples were removed and stored dry. Observe the surface morphology of the sample by SEM: the nanotubes are arranged in an orderly and compact manner, the nanotubes have a complete shape, the maximum diameter of the nanotubes is about 250nm, and the average diameter of the nanotubes is about 200nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com