Industrial sewage processing unit and industrial sewage process method

A technology for industrial sewage and treatment equipment, which is applied in the direction of flotation water/sewage treatment, oxidized water/sewage treatment, multi-stage water/sewage treatment, etc. It can solve the problem of reducing the efficiency of municipal sewage treatment systems, affecting the economic development of small and medium-sized enterprises, Solve problems such as long time to achieve the effect of improving the sorting efficiency of the device, short reaction time and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

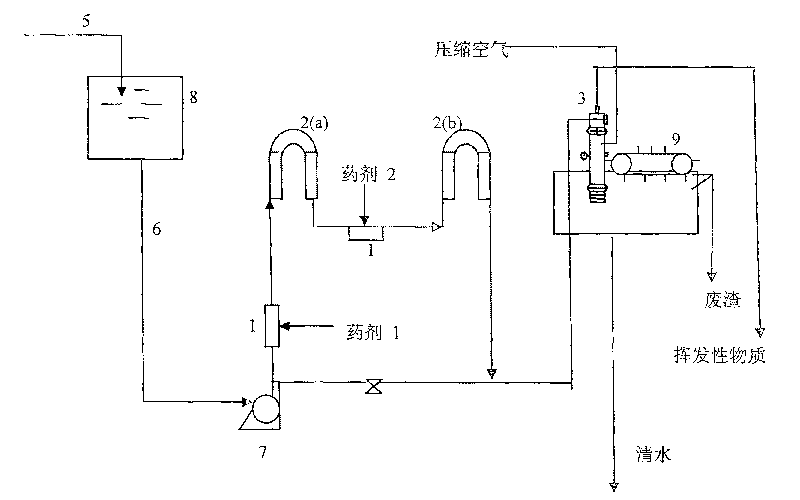

[0047] Embodiment 1 (treatment of oily sewage)

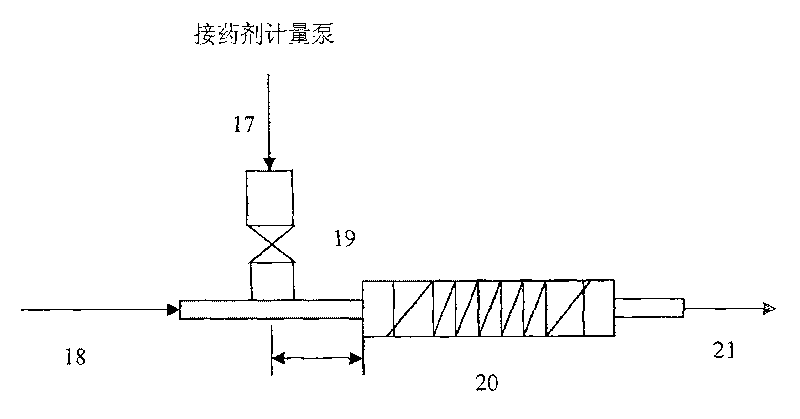

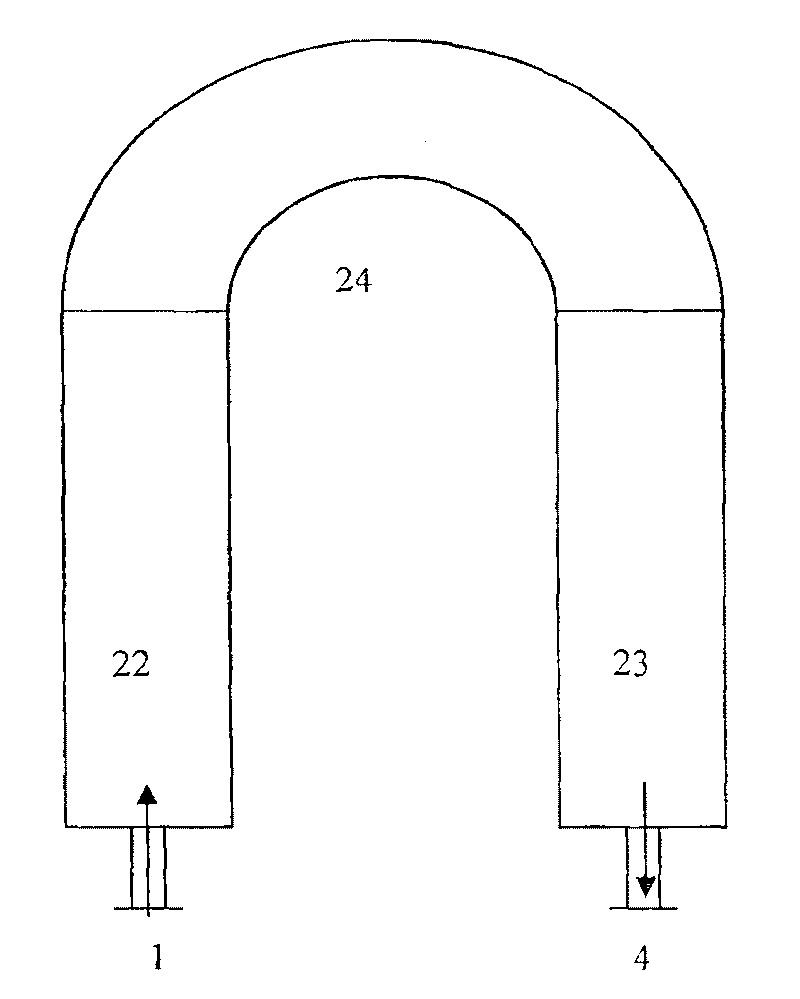

[0048] Oily sewage with 4.5m 3 / h flow pumped into the drug mixing device 1, the FeCl 3 Coagulant (FeCl 3 (purchased from Wenzhou Tiansheng Electrochemical Co., Ltd.) inject 5 to 10 mg per liter of oily sewage into the water pipeline and mix with the oily sewage. The mixed solution enters the first-stage U-shaped flocculation mixing pipe 2 (a), And stay for 1 to 2 minutes. The polyacrylamide flocculant (polyacrylamide purchased from ALLIED COLLLOIDS company in the United States) was remixed with the sewage discharged from the first-stage U-shaped flocculation slurry pipe 2 (a) at an amount of 10 mg per liter of oily sewage. After mixing, it enters the second-stage U-shaped flocculation slurry mixing pipe 2 (b). The sewage after pulping is injected into the hydrocyclone aeration decontamination device 3 in a tangential direction, and at the same time, compressed air with a pressure of 68.9kpa is injected from the microporous ...

Embodiment 2

[0051] Embodiment 2 (the air stripping process that contains dichloromethane wastewater) (Air Stripping)

[0052] The sewage containing methylene chloride is directly pumped into the HAD decontamination device 3 at a flow rate of 70L / min, and the compressed air is removed by hydrocyclone aeration at a flow rate of 1850L / min, 3750L / min, 3936L / min, and 5000L / min respectively. The microporous air disperser of the dirty container 3 is injected, and the organic volatile methylene chloride leaves the liquid phase with the air, and the removal rate increases with the increase of the air flow rate, and the volatilized organic matter is absorbed by an absorption box equipped with activated carbon. The following table 2 is the actual detection result of dichloromethane before and after the treatment of the sewage containing dichloromethane in the present embodiment:

[0053] Table 2.

[0054]

Embodiment 3

[0055] Embodiment 3 (treatment of printing and dyeing wastewater)

[0056] Contains printing and dyeing sewage in 2m 3 The flow rate per hour is pumped into the dosing mixing device 1, and the pH is adjusted to 2.5-3 with hydrochloric acid (hydrochloric acid from Hebei Donghao Chemical Co., Ltd.), and the mixed solution enters the first-stage U-shaped flocculation mixing pipe 2 (a ), and stay for 1 to 2 minutes. The polyacrylamide flocculant (polyacrylamide purchased from ALLIED COLLLOIDS in the United States) was remixed with the sewage discharged from the first-stage U-shaped flocculation mixing pipe 2 (a) at an amount of 20 mg per liter of printing and dyeing sewage. After mixing, it enters the second-stage U-shaped flocculation slurry mixing pipe 2 (b). The sewage after pulping is injected into the hydrocyclone aeration decontamination device 3 in a tangential direction, and at the same time, the compressed air with a pressure of 68.9kpa is injected from the microporous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com