Microwave method for preparing cadmium hydroxide nano materials

A nano-material, cadmium hydroxide technology, applied in chemical instruments and methods, cadmium compounds, inorganic chemistry, etc., can solve problems such as long time, achieve fast reaction speed, increase crystallization speed, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] ①In a 30ml reaction bottle, dissolve 1 part of cadmium salt in 1000 parts of water, then add concentrated ammonia water to form a clear and transparent cadmium complex ion solution, then add 100 parts of n-octanol, 1 part of dodecyl sulfate Na, stir vigorously, and let stand for 2 hours.

[0023] ②Transfer the reaction solution prepared according to step ① into a 50ml polytetrafluoroethylene reactor, and irradiate with pulsed microwave for 3 minutes with a pulsed microwave power of 500w. After the reaction, the reaction kettle is naturally cooled to 60° C., the product is filtered, washed with absolute ethanol and water several times, and vacuum-dried to obtain the cadmium hydroxide nanomaterial.

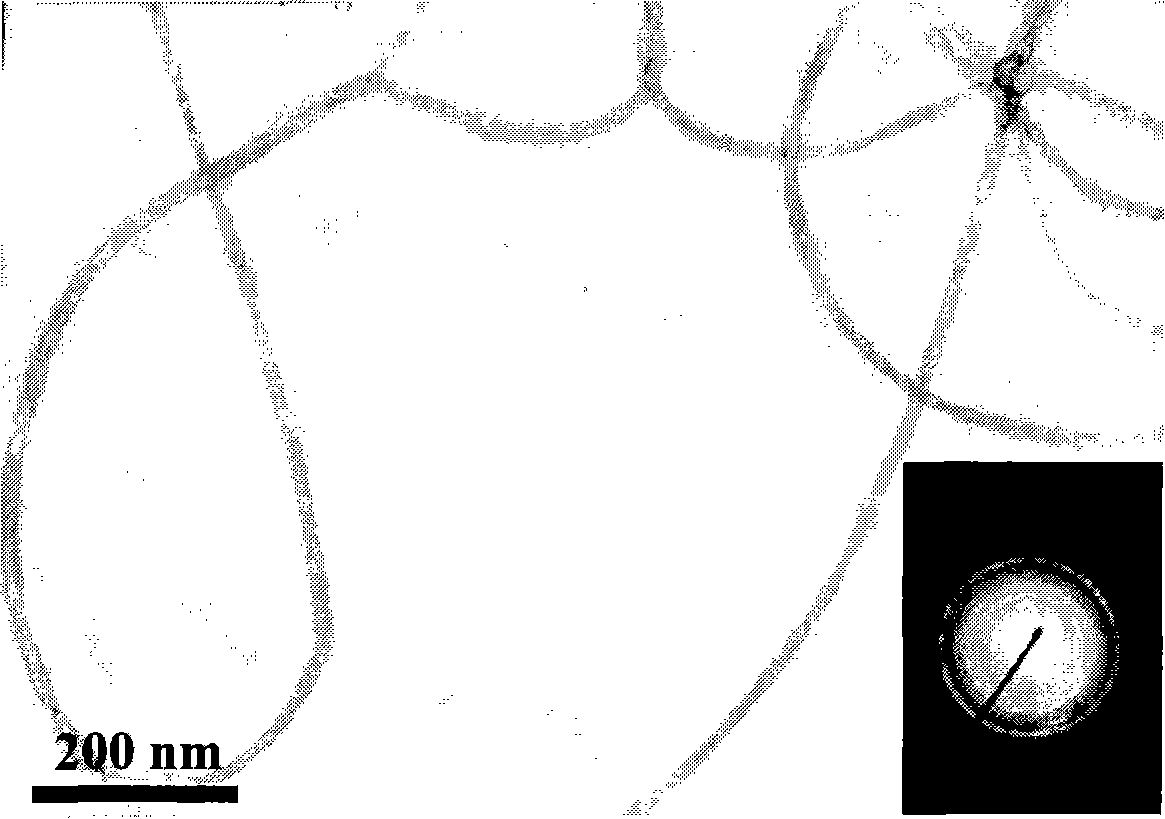

[0024] figure 1 It is a transmission electron micrograph and an electron diffraction pattern of the obtained cadmium hydroxide nanomaterial. It can be seen from the figure that the cadmium hydroxide nanomaterial has a polycrystalline one-dimensional necklace-like structure...

Embodiment 2

[0026] ①In a 30ml reaction bottle, dissolve 10 parts of cadmium salt in 1000 parts of water, then add 100 parts of sodium hydroxide to form a clear and transparent cadmium complex ion solution, then add 1000 parts of n-octanol, 1 part of Qular Ketones, stirred vigorously, let stand for 1 hour.

[0027] ②Transfer the reaction solution prepared according to step ① into a 50ml polytetrafluoroethylene reactor, and irradiate with pulsed microwave for 10 minutes with a pulsed microwave power of 300w. After the reaction, the reaction kettle is naturally cooled to 60° C., the product is filtered, washed with absolute ethanol and water several times, and vacuum-dried to obtain the cadmium hydroxide nanomaterial.

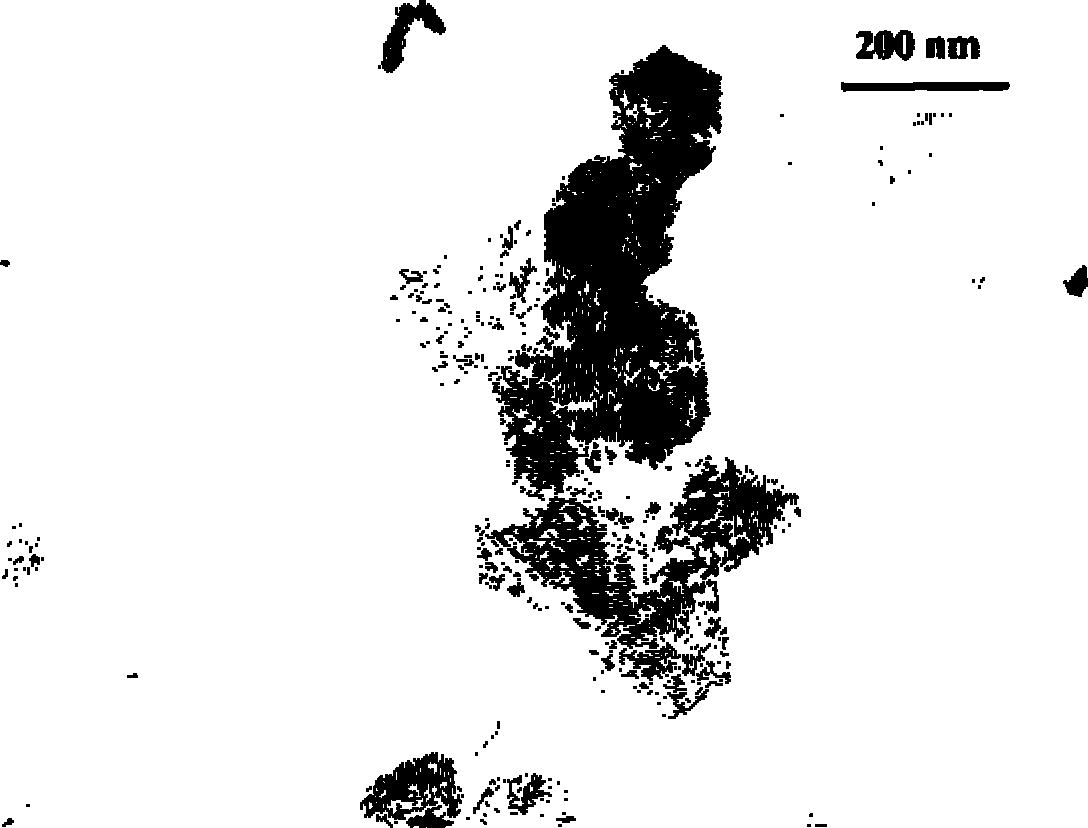

[0028] The transmission electron micrograph of the obtained cadmium hydroxide nanomaterial is as follows: figure 2 shown. It can be seen from the figure that the cadmium hydroxide nanomaterial has a hexagonal sheet structure.

Embodiment 3

[0030] ①In a 30ml reaction bottle, dissolve 10 parts of cadmium salt in 1000 parts of water, then add concentrated ammonia water to form a clear and transparent cadmium complex ion solution, add 1000 parts of n-octanol, and then add 6 parts of dodecyl Sodium sulfate, stir vigorously for 1 min, let stand for 2 hours.

[0031] ②Transfer the reaction solution prepared according to step ① into a 50ml polytetrafluoroethylene reactor, and irradiate with pulsed microwave for 1 minute with a pulsed microwave power of 800w. After the reaction, the reaction kettle is naturally cooled to 60° C., the product is filtered, washed with absolute ethanol and water for several times, and vacuum-dried to obtain the cadmium hydroxide hollow nanomaterial.

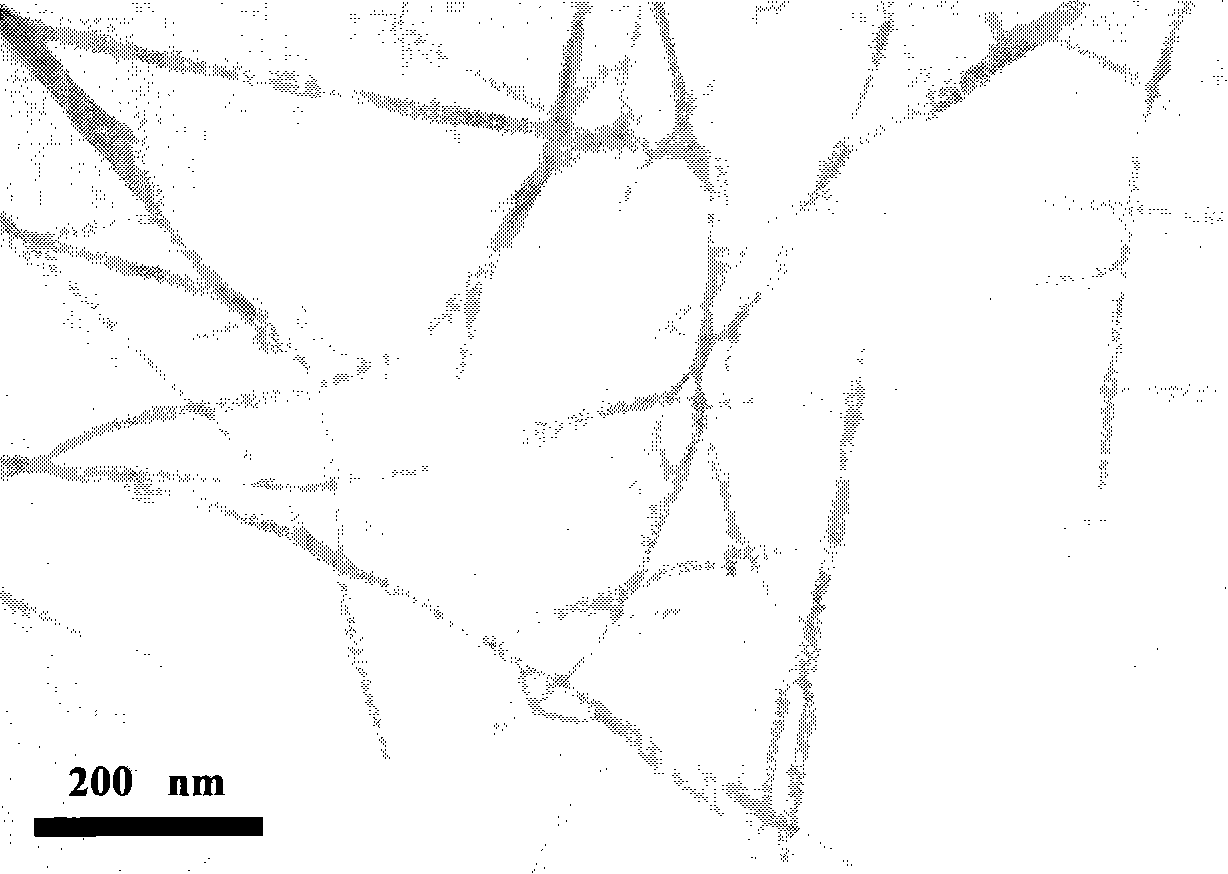

[0032] The transmission electron micrograph of the obtained cadmium hydroxide nanomaterial is as follows: image 3 shown. It can be seen from the figure that the cadmium hydroxide nanomaterial is a short one-dimensional necklace-like structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com