Flexibility enhanced bipolar plate for liquid energy-storing battery and manufacture thereof

A liquid flow energy storage battery and flexible graphite technology, which is applied in the direction of electrode manufacturing, fuel cell parts, active material electrodes, etc., can solve the problems of battery Coulombic efficiency decline, poor mechanical properties, and poor liquid resistance, etc., to achieve Effects of improving assembly conditions, improving mechanical properties, and good liquid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

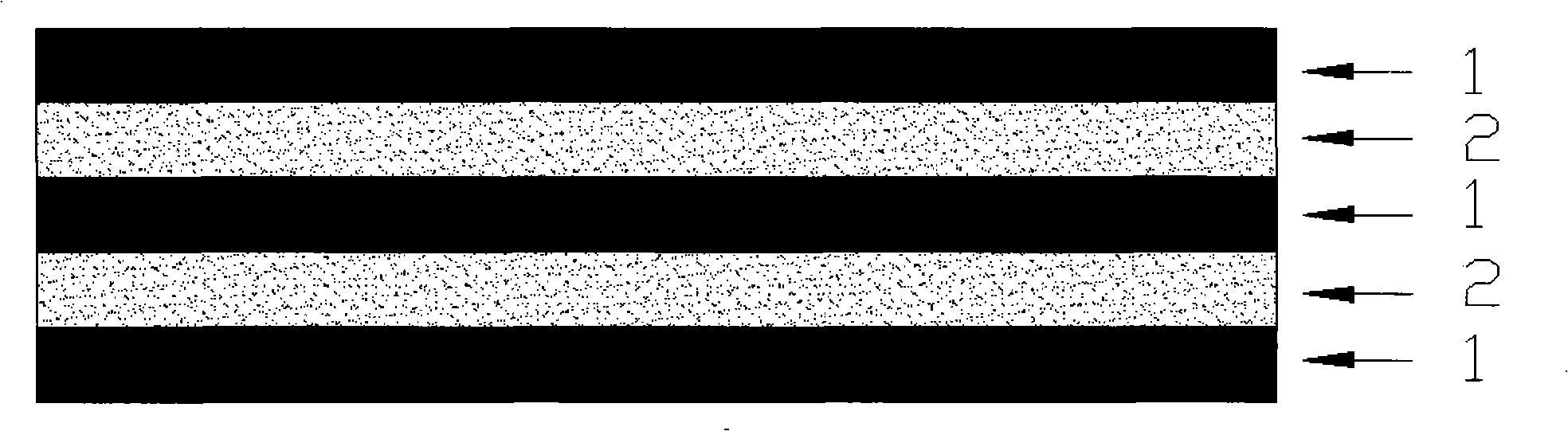

[0041] Get graphite powder 6g, graphite fiber 1g, polypropylene resin powder 3g, stir at high speed for 10 minutes / time, stirring times 2 times, stirring speed 5000 rpm. The obtained mixture was uniformly added to a frame provided with a flexible graphite plate with a thickness of 0.3 mm, and then another flexible graphite plate with a thickness of 0.3 mm was stacked on the graphite and polypropylene mixture layer. Hot pressing at 210°C and 30 MPa pressure for 5 minutes can obtain the reinforced flexible graphite bipolar plate for the flow energy storage battery.

Embodiment 2

[0043] Take 9g of graphite powder and 1g of polyoxymethylene resin powder, stir at high speed for 5 minutes / time, the number of times of stirring is 4 times, and the stirring speed is 2000 rpm. Then weigh 0.2 g of carbon fiber and stir it together with the mixture of graphite and polyoxymethylene at high speed for 10 minutes / time, the number of times of stirring is 2 times, and the stirring speed is 2000 rpm. Add the obtained mixture evenly to the mold frame with a flexible graphite plate with a thickness of 0.5mm, and then stack another flexible graphite plate with a thickness of 0.5mm on the mixture layer of graphite, polyoxymethylene and carbon fiber superior. The reinforced flexible graphite bipolar plate for the flow energy storage battery can be obtained by hot pressing at 190°C and 50 MPa pressure for 10 minutes.

Embodiment 3

[0045] Weigh 8g of carbon black and 2g of polyphenylene ether powder, stir at high speed for 5 minutes / time, 4 times, and the stirring speed is 2000 rpm. The obtained mixture was uniformly added to a mold frame with a flexible graphite plate with a thickness of 0.3 mm, and then another flexible graphite plate with a thickness of 0.3 mm was stacked on the graphite and polyphenylene ether mixture layer. Place them in the order above, and the total number of layers is 5 layers. By hot pressing at 290°C and 30 MPa pressure for 20 minutes, the reinforced flexible graphite bipolar plate for the flow energy storage battery can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com