High combination property laser crystal and method for making same

A laser crystal, comprehensive performance technology, applied in crystal growth, chemical instruments and methods, single crystal growth and other directions, can solve the problems of reducing thermal effect and thermal lens effect, low technical repeatability, easy deformation of bonding surface, etc. The effect of uniform density pumping without damage, improving laser output power and improving beam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

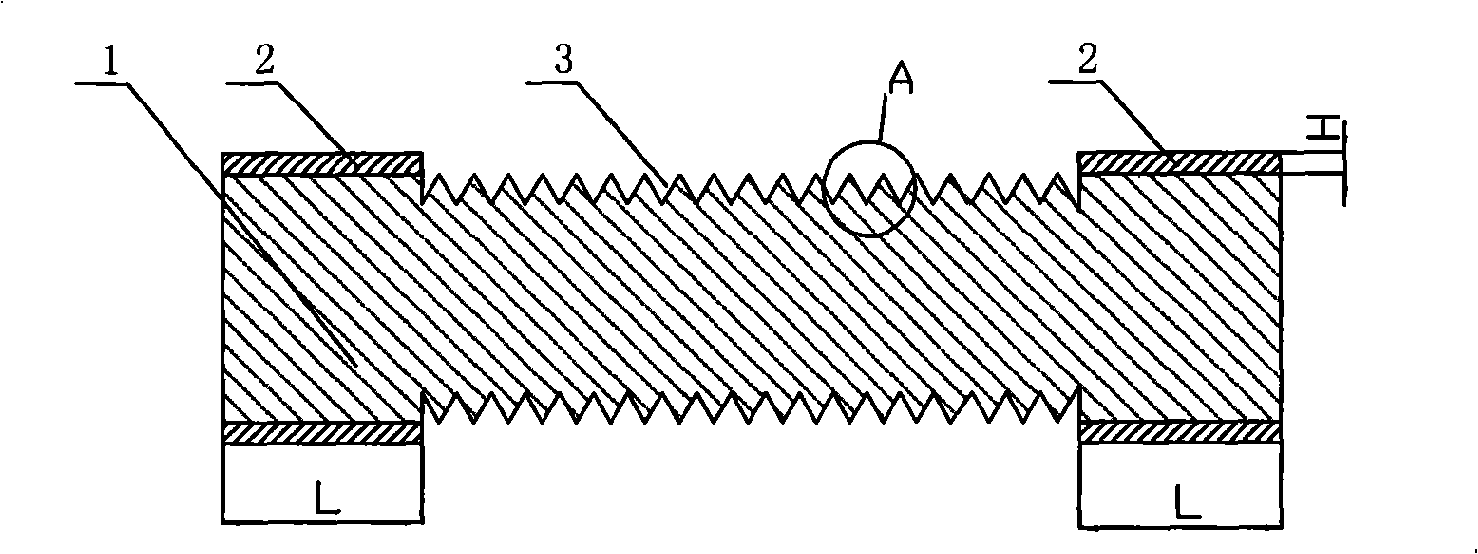

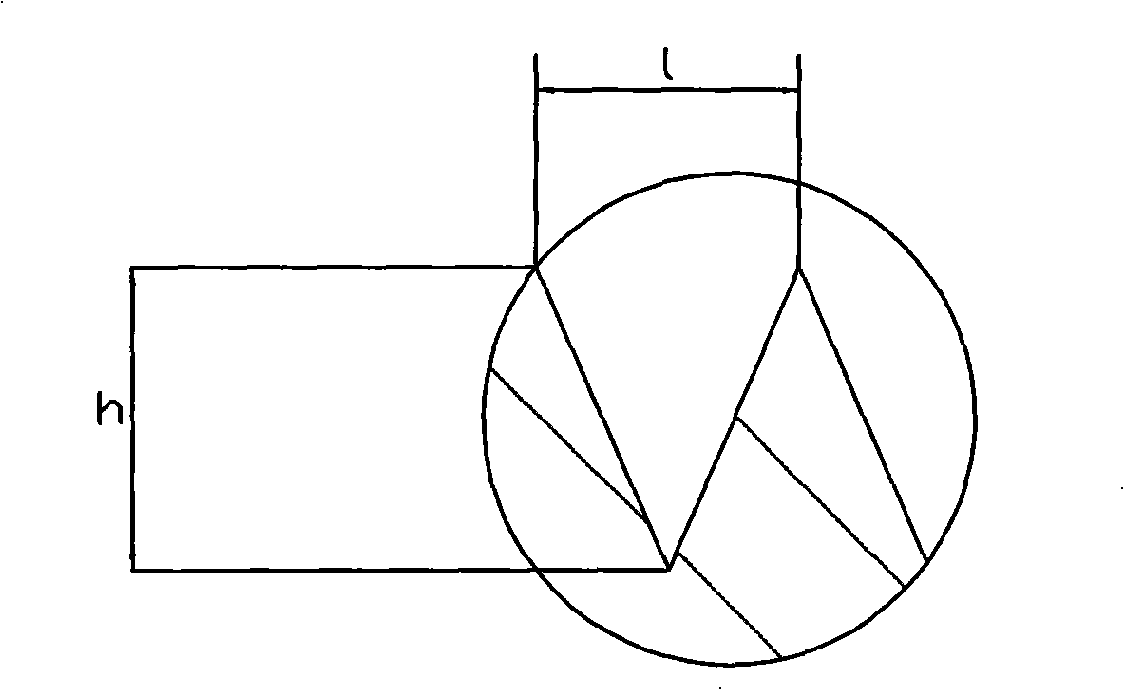

[0019] Such as figure 1 , figure 2 As shown, a laser crystal with high comprehensive performance includes Nd:YAG, (Nd, Ce):YAG, (Nd, Ce, Tb):YAG, (Cr, Tm, Ho):YAG, (Tm, Ho) :YAG, Ho:YAG, Er:YAG, Yb:YAG, Nd:GGG, Yb:GGG, Nd:YAP rod-shaped laser crystal 1 with any matrix, and the cylindrical surfaces of both ends of the rod-shaped laser crystal 1 are provided with high thermal conductivity A coating layer 2 of heat dissipation material, the axial length L of the coating layer 2 from the end face is 5-10mm, the thickness H of the coating layer 2 is 0.01-0.2mm, and the non-coated part of the cylinder on the rod-shaped laser crystal The surface has a thread structure, wherein the thread pitch 1 is 0.2-3.0 mm, and the depth h is 0.05-0.3 mm. Gold is used as the heat dissipation material with high thermal conductivity in this embodiment.

[0020] A preparation method of the above-mentioned high comprehensive performance laser crystal, comprising the steps of:

[0021] A. Choose n...

Embodiment 2

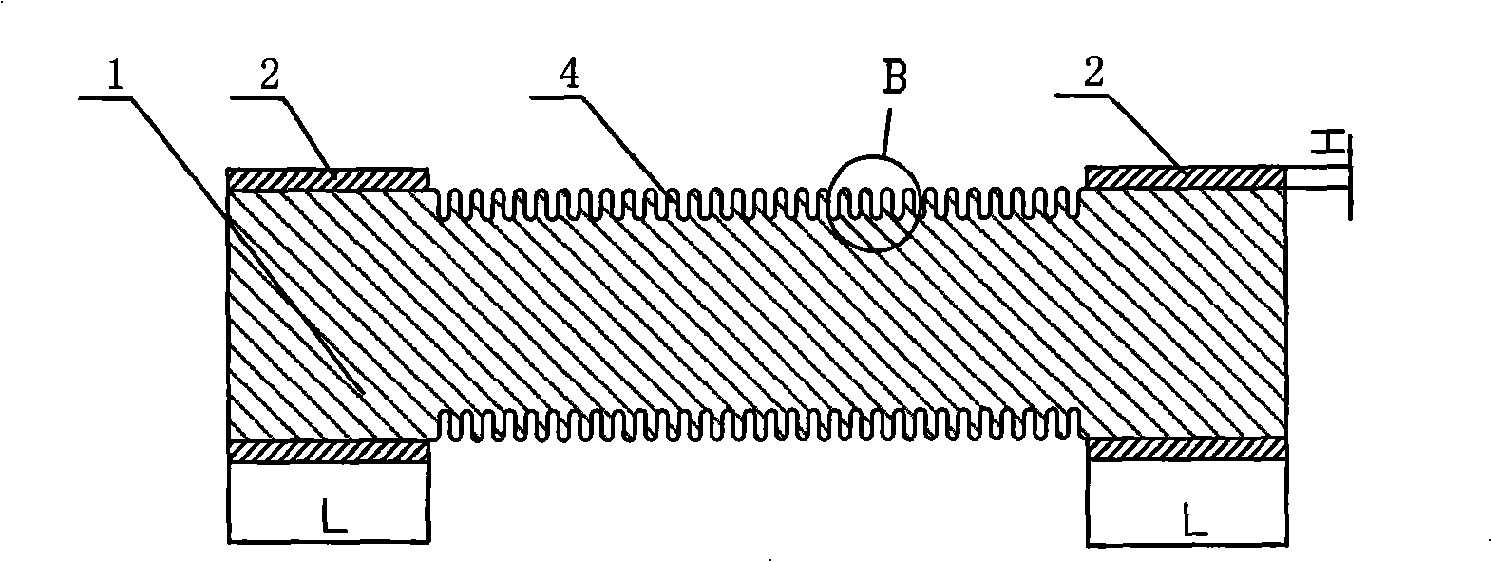

[0025] Such as image 3 , Figure 4 As shown, a laser crystal with high comprehensive performance includes Nd:YAG, (Nd, Ce):YAG, (Nd, Ce, Tb):YAG, (Cr, Tm, Ho):YAG, (Tm, Ho) :YAG, Ho:YAG, Er:YAG, Yb:YAG, Nd:GGG, Yb:GGG, Nd:YAP rod-shaped laser crystal 1 with any matrix, and the cylindrical surfaces of both ends of the rod-shaped laser crystal 1 are provided with high thermal conductivity A coating layer 2 of heat dissipation material, the axial length L of the coating layer 2 from the end face is 5-10mm, the thickness H of the coating layer 2 is 0.01-0.2mm, and the non-coated part of the cylinder on the rod-shaped laser crystal The surface has a ring structure, wherein the distance 1 of the ring structure is 0.2-3.0 mm, and the depth h is 0.05-0.3 mm. In this embodiment, copper is used as the heat dissipation material with high thermal conductivity.

[0026] A preparation method of the above-mentioned high comprehensive performance laser crystal, comprising the steps of:

...

Embodiment 3

[0031] A laser crystal with high comprehensive performance, including Nd:YAG, (Nd, Ce):YAG, (Nd, Ce, Tb):YAG, (Cr, Tm, Ho):YAG, (Tm, Ho):YAG, Ho:YAG, Er:YAG, Yb:YAG, Nd:GGG, Yb:GGG, Nd:YAP rod-shaped laser crystal 1 with any matrix, and the cylindrical surfaces of both ends of the rod-shaped laser crystal 1 are equipped with heat dissipation materials with high thermal conductivity Coating layer 2, the axial length L of the coating layer 2 from the end face is 10mm, the thickness H of the coating layer 2 is 0.2mm, and the non-coating part of the cylindrical surface on the rod-shaped laser crystal is a thread structure, wherein, The thread pitch 1 is 3.0 mm, and the depth h is 0.3 mm. Silver is used as the heat dissipation material with high thermal conductivity in this embodiment. The high comprehensive performance laser crystal structure of the present embodiment is the same as figure 1 , figure 2 shown.

[0032] A preparation method of the above-mentioned high comprehens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com