Method for detecting perfuming homogeneity of cigarette production based on marker

A technology of markers and uniformity, which is applied in the direction of measuring devices, instruments, and material analysis through electromagnetic means, can solve the problems of inaccurate control and adjustment, and the inability to obtain the effect of fragrance application, etc., and achieves high degree of automation and fast speed , to avoid the effect of uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Marker selection test

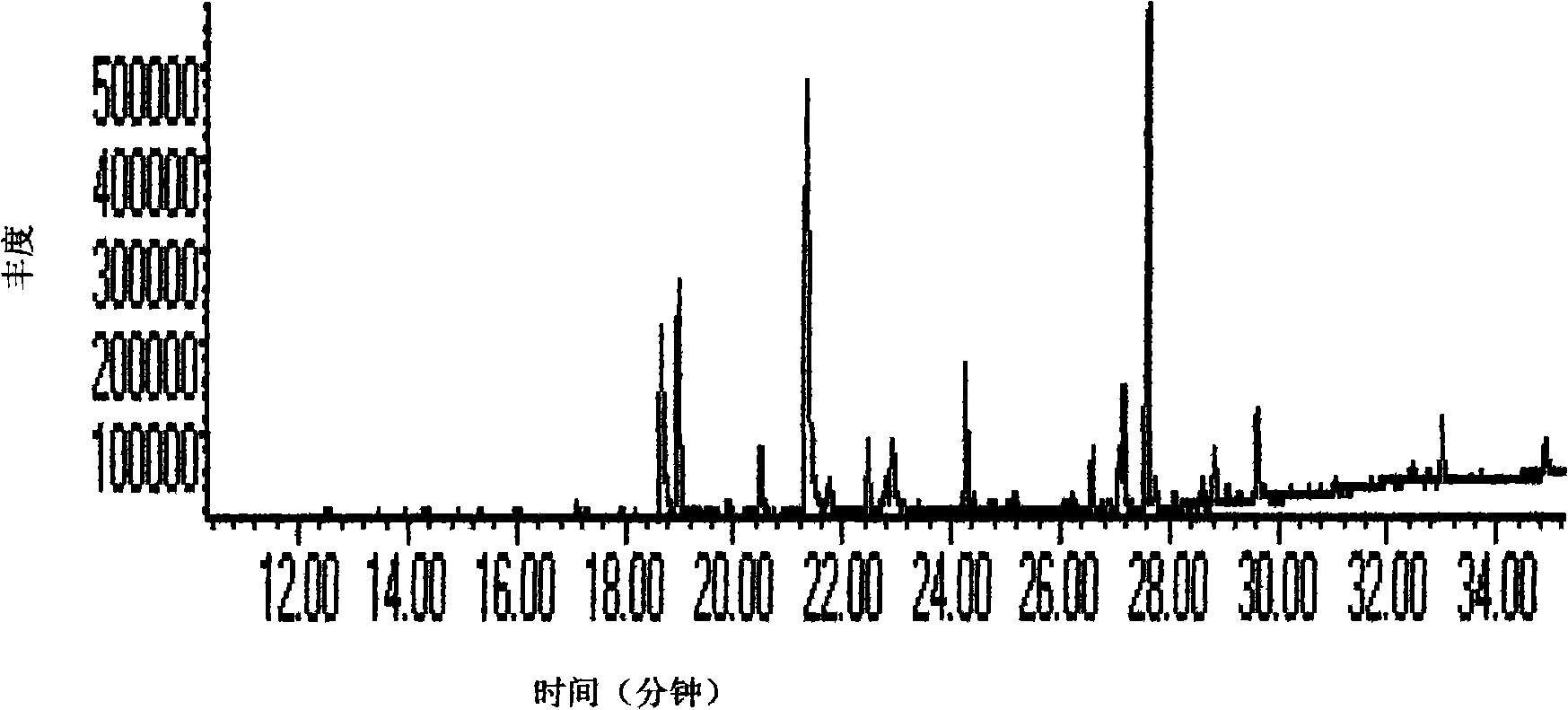

[0034] Take 2 equal portions of unflavored shredded tobacco from a certain brand of cigarettes, one portion is used as a blank sample, and the other portion is flavored according to the normal amount of flavoring. Dry the shredded tobacco sample at a temperature of about 40°C, grind it and pass it through a 40-mesh sieve, accurately weigh 25g of tobacco powder, and process it with a distillation extraction apparatus to obtain 40mL of dichloromethane extract Add 3g of anhydrous sulfuric acid Sodium, let it stand overnight, filter, concentrate in a rotary evaporator to 1mL, shake well, and take a sample for GC / MS analysis and identification. The analysis conditions are: HP-Innowax capillary column (60m×0.25mm×0.25μm); Gas: He, flow rate 1.0mL / min; inlet temperature: 260°C; box temperature: initial temperature 60°C, hold for 1min, increase to 250°C at 10°C / min, hold for 5min; transfer line temperature: 280°C; Energy: 70eV; EI ion source ...

Embodiment 2

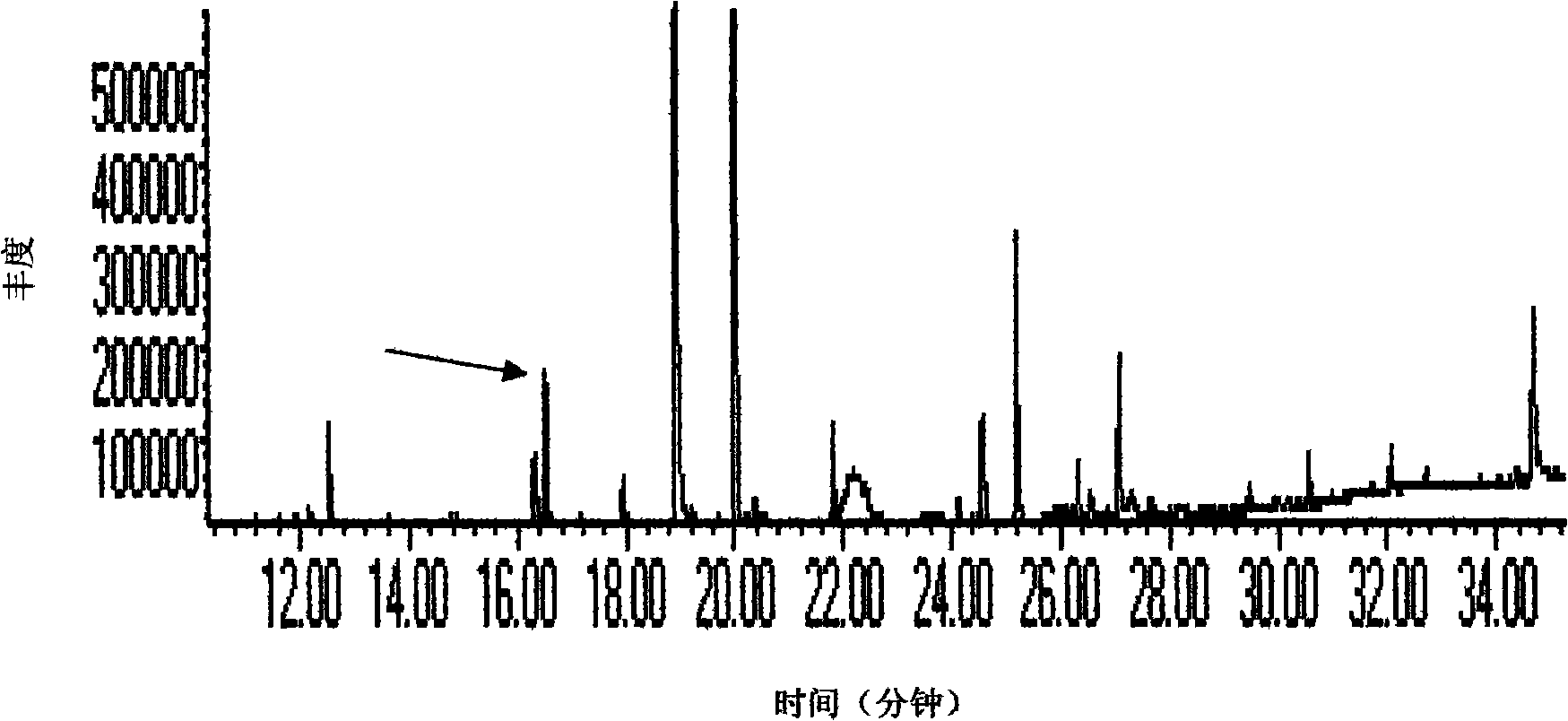

[0036] Embodiment 2: Analytical method test

[0037] Put the shredded tobacco sample in a balance box (temperature 20°C±1, relative humidity 60%±3) to balance for 24 hours, and then use a fast solvent extraction apparatus to pre-treat the shredded tobacco sample. The extraction conditions are: take 6.0g shredded tobacco sample and put it into 34mL In the extraction pool, the extraction solvent is dichloromethane, the liquid supply pressure is set to 1500psi, the temperature is 130°C, the static extraction time is 5min, rinsed with 60% washing solution, the number of cycles of static extraction and solvent flushing is 1, and nitrogen gas is used to Purge for 100s. Obtain all the extracts and record the volume as VmL. Use a 10mL syringe to draw 2-5mL of the extract, filter it through a 0.45μm filter membrane, collect 1mL of the filtrate with a chromatographic sample, shake it up, and then conduct GC / MS analysis.

[0038] The analysis conditions of GC / MS are: HP-Innowax capilla...

Embodiment 3

[0053] Embodiment 3: Uniformity determination test

[0054] When the process parameters of the flavoring drum are set as follows: the flow rate is 6400kg / h, the air pressure of the atomizing medium is 0.3MPa, and the drum speed is 9r / min. After the equipment is running stably, 30 samples are continuously randomly selected from the exit of the aromatizing drum every 1 minute or so, each sample is about 10g, and placed in a plastic sealing tape. The determination of the marker menthol content in the shredded tobacco sample was carried out according to the method in Example 2, and the obtained results are shown in Table 5 below. It can be seen from Table 5 that under the operating state of the equipment, the uniformity of cigarette flavoring expressed by SD is 14.66.

[0055] Table 5 Test results of flavoring uniformity of cigarettes (μg / g shredded tobacco)

[0056]

[0057]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com