Automatic processing product line for source nipple of gas cylinder

A threaded interface and automatic processing technology, which is applied in the direction of metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of low processing efficiency and low processing accuracy, and achieve the goals of improving efficiency, strong practicability, and reducing equipment costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

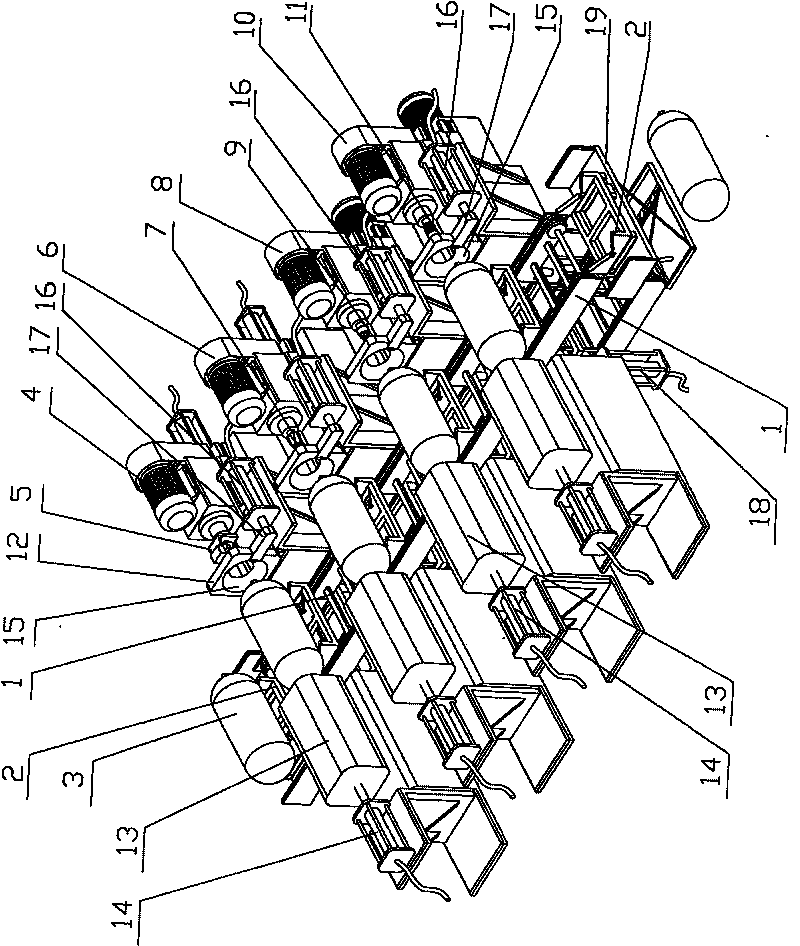

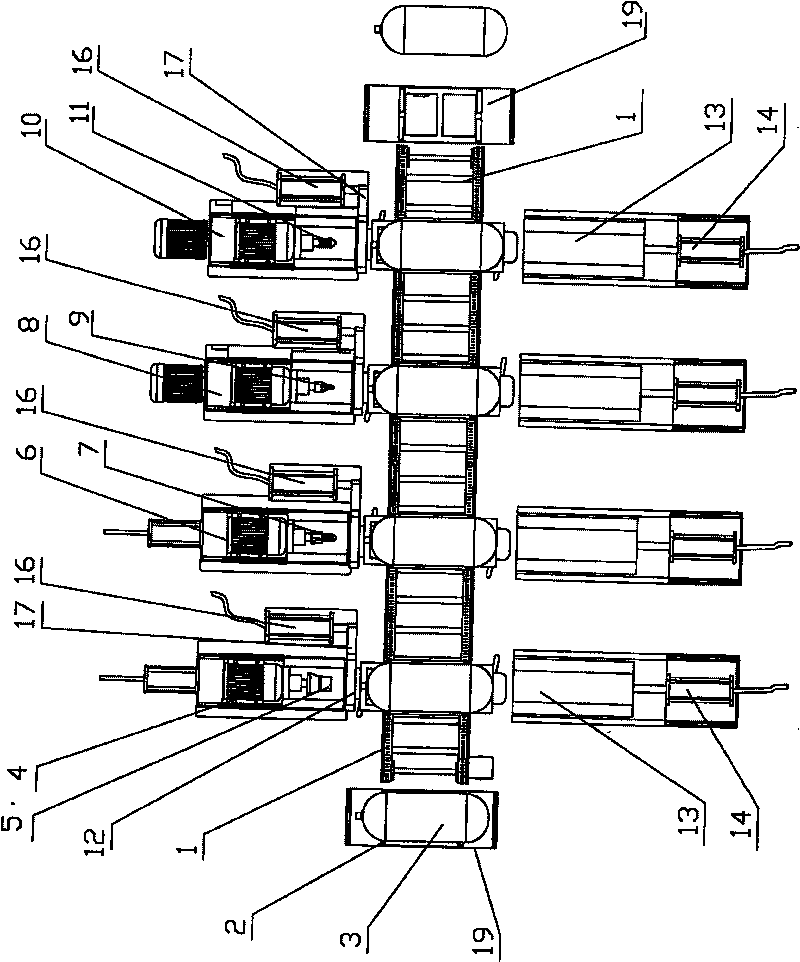

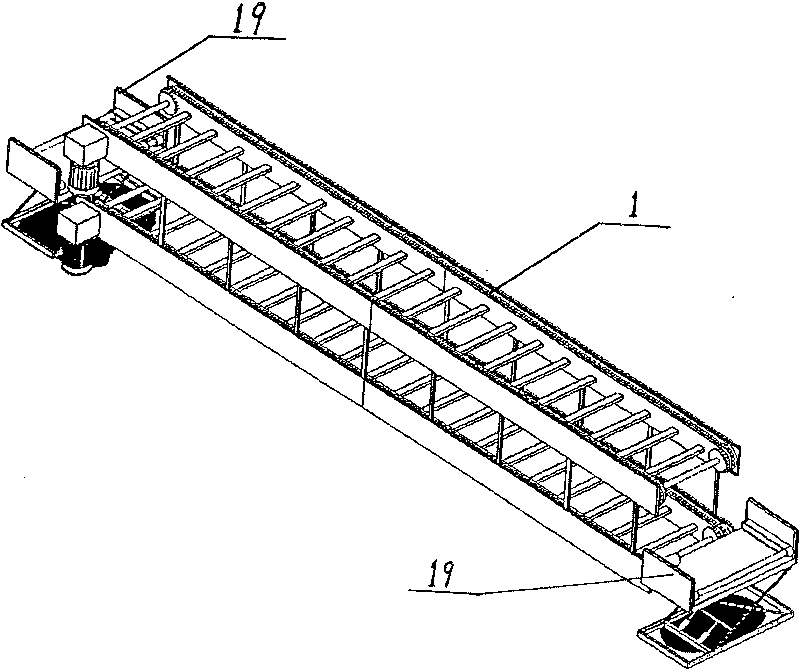

[0031] Such as figure 1 , 2 Middle, 1-conveyor belt, 2-V-shaped pallet, 3-steel cylinder to be processed, 4-sinking machine, 5-sinking compound tool, 6-drilling and reaming machine, 7-drilling and reaming compound tool, 8-fine reaming Angle machine tool, 9-fine reaming and chamfering compound tool, 10-tapping machine tool, 11-tapping rod, 12-fixture fixed block, 13-fixture moving block, 14-clamping power cylinder, 15-positioning round table hole, 16-Ejecting power cylinder, 17-Ejecting block, 18-Lifting power cylinder, 19-Elevating platform,

[0032] The gas cylinder threaded joint automatic processing production line of the present invention comprises a PLC electrical control system and a conveyor belt 1. The PLC electrical control system selects a programmable control system of the prior art, which can control the processing time of the automatic processing production line of the present invention, the opening and closing of the power cylinder Shutdown, opening and closing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com