Method for preparing high purity polysilicon particle with fluidized bed and bed fluidizing reactor

A fluidized bed reactor and polysilicon technology, applied in chemical instruments and methods, from chemically reactive gases, polycrystalline material growth, etc., can solve the problem of separating the heating zone from the reactor, deposition on the wall of the heating zone, silicon-containing Reaction gas back-mixing and other problems, to achieve the effect of great flexibility, silicon deposition inhibition, and reduce overall energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

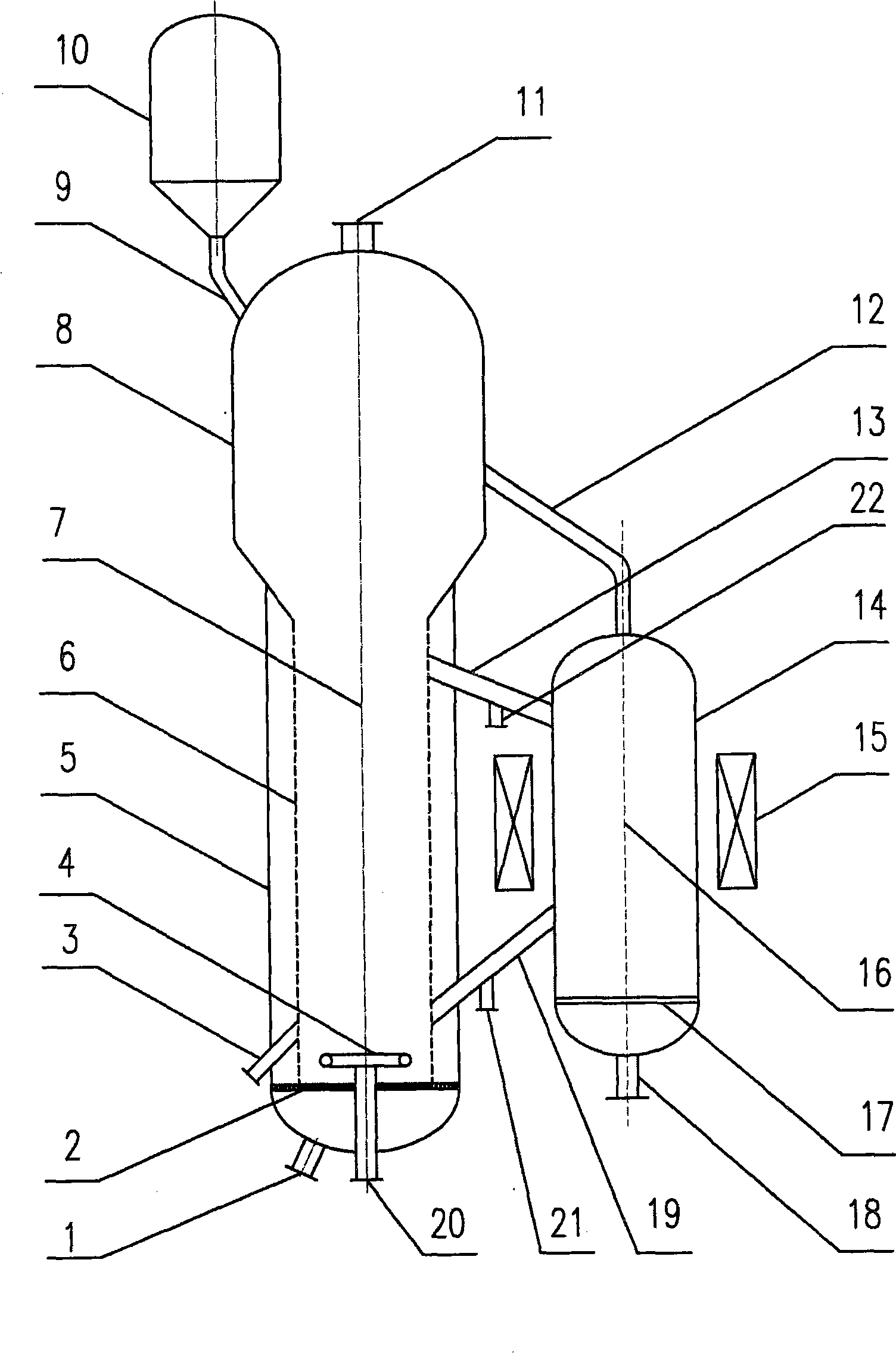

[0032] The specific implementation manner of preparing high-purity granular polysilicon particles by using a fluidized bed reactor according to a preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0033] figure 1 Schematic diagram of the structure of the embodiment of the fluidized bed reactor provided by the present invention. In this embodiment, the fluidized bed reactor comprises a reaction zone cylinder wall 5, a perforated guide cylinder 6 coaxial with the reactor cylinder wall and a reaction zone 7 inside thereof, and the reaction zone located at the lower part of the reaction zone 7 is fluidized. Gas distributor 2 and fluidization gas inlet 1 in the reaction zone, polysilicon particle product outlet 3 connected to the lower part of the perforated draft tube, expansion section 8 located at the upper part of the reaction zone, silicon seed storage tank 10 located at the upper part of the expanded ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap