Cleaning and recycling process for by-product sodium sulfite of cartap

A technology of by-product sodium sulfite and sodium sulfite, applied in the preparation of alkali metal sulfite, purification of alkali metal sulfite/sulfate, heating water/sewage treatment, etc., can solve resource waste, high energy consumption, environmental pollution, etc. problem, to achieve the effect of solving pollution, high yield and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

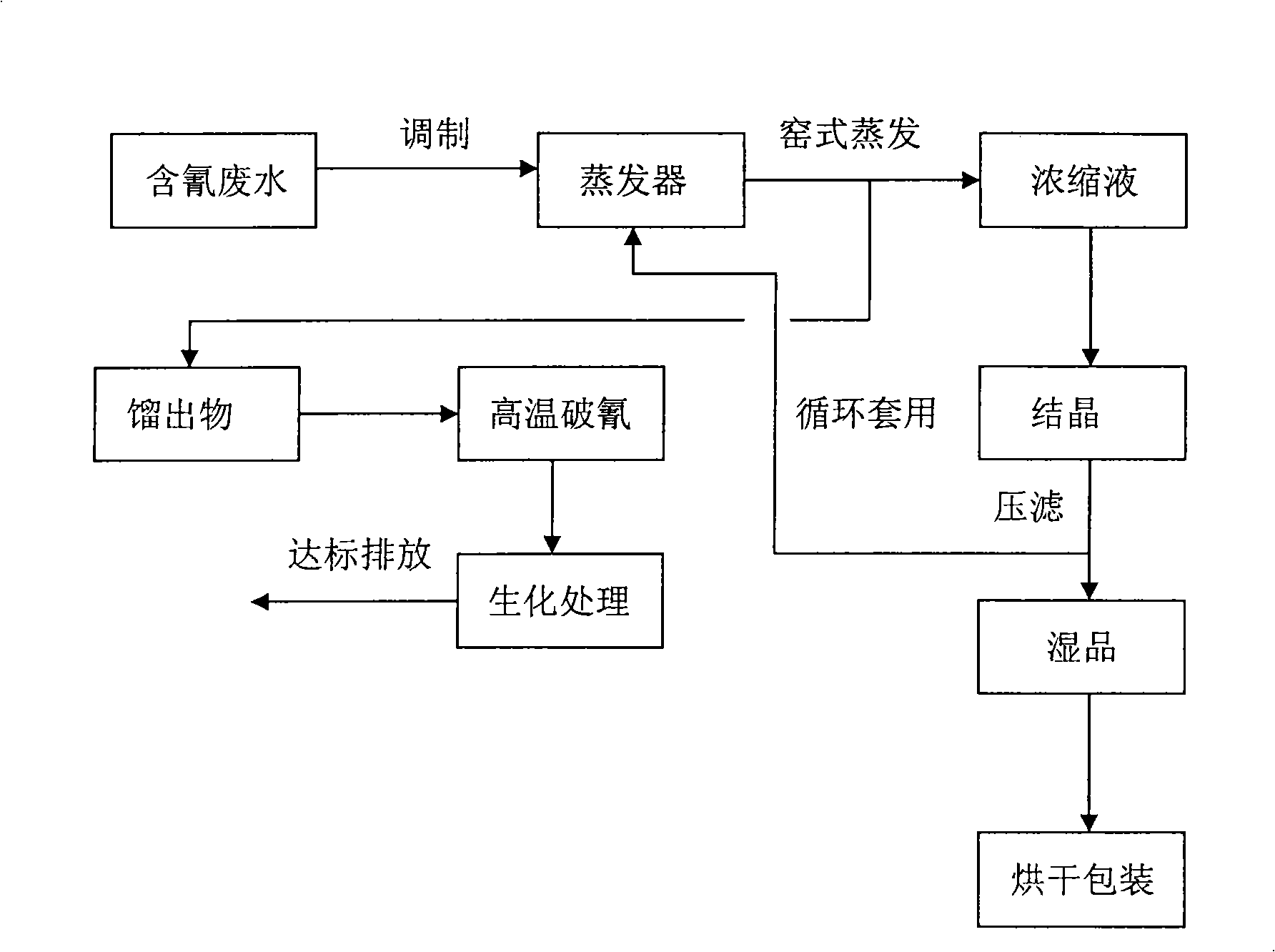

Method used

Image

Examples

Embodiment 1

[0018] Collect 1000kg of cyanide-containing waste water in the production process of saquat and store it in a container with slightly positive pressure, wherein the weight content of sodium sulfite is 18%, CN - The weight content of water is 2500ppm; the water weight content is 78%. Adjust the pH value of the cyanide-containing wastewater to 11-12 with 30% aqueous sodium hydroxide solution, add it to the evaporation kiln, heat and pressurize at 85°C and 0.07Mpa for condensation, impurities CN - It is carried out with water vapor and collected by multi-stage condensation, and the recovery rate reaches 98%. The collected evaporative condensed CN-containing - The water of the cyanide is broken at a high temperature at a temperature of 110 ° C and a pressure of 0.4 MPa, so that the CN - The content decreased, and the wastewater contained CN after the cyanide was broken. - It is 2 to 5ppm and ammonia nitrogen is 200ppm. The cyanide-broken wastewater enters the wastewater treatm...

Embodiment 2

[0020] Collect the cyanide-containing waste water 1000kg and the 115kg filtrate of Example 1 in the production process of cyanide, store in the container with a little positive pressure, wherein the weight content of sodium sulfite in the cyanide-containing waste water is 18%, CN - The weight content of water is 2500ppm; the water weight content is 78%. Adjust the pH value of the cyanide-containing wastewater to 11-12 with 25% aqueous sodium hydroxide solution, add it to the evaporation kiln, and heat and condense it at 90 ° C, impurities CN - It is carried out with water vapor and collected by multi-stage condensation, and the recovery rate reaches 98%. The collected evaporative condensed CN-containing - The water of the cyanide is broken at high temperature at a temperature of 100 ° C and a pressure of 0.5 MPa, so that the CN in it - The content decreased, and the wastewater contained CN after the cyanide was broken. - It is 2 to 5ppm and ammonia nitrogen is 200ppm. The ...

Embodiment 3

[0022] Collect the cyanide-containing waste water 1000kg and the 110kg filtrate of Example 2 in the production process of cyanide, be stored in the container with a little positive pressure, wherein the weight content of sodium sulfite in the cyanide-containing waste water is 18%, CN - The weight content of water is 2500ppm; the water weight content is 78%. Adjust the pH value of the cyanide-containing wastewater to 11-12 with 35% sodium hydroxide aqueous solution, add it to the evaporation kiln, heat and pressurize at 80 ° C and 0.08 Mpa for condensation, impurities CN - It is carried out with water vapor and collected by multi-stage condensation, and the recovery rate reaches 98%. The collected evaporative condensed CN-containing - The water of the cyanide is broken at a high temperature at a temperature of 120 ° C and a pressure of 0.3 MPa, so that the CN - The content decreased, and the wastewater contained CN after the cyanide was broken. - It is 2 to 5ppm and ammonia ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com