Method and apparatus for removing and recycling organic phase in wastewater with distillation-free complete-molecular sieve

An organic phase and molecular sieve technology, applied in separation methods, chemical instruments and methods, water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

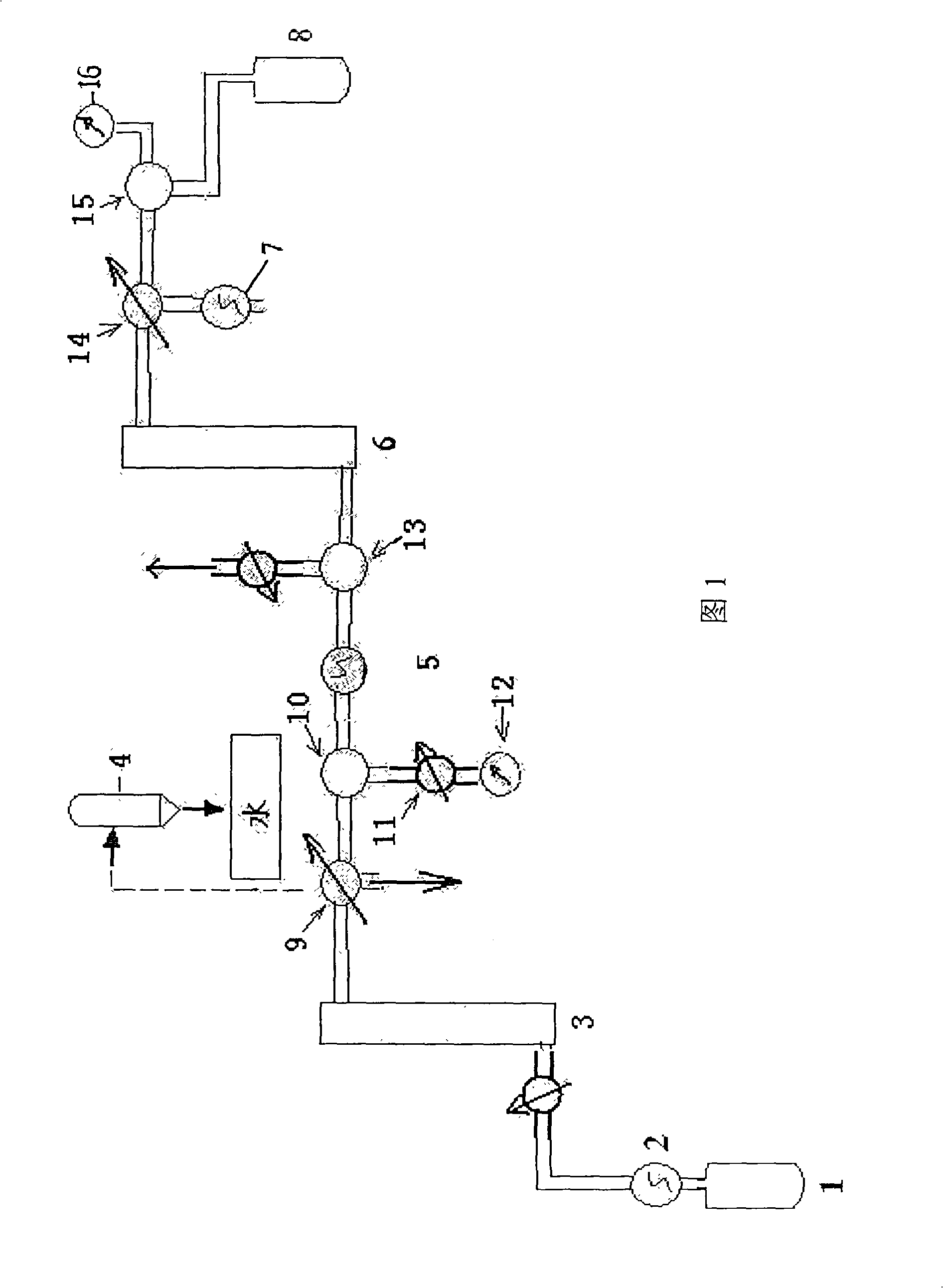

Method used

Image

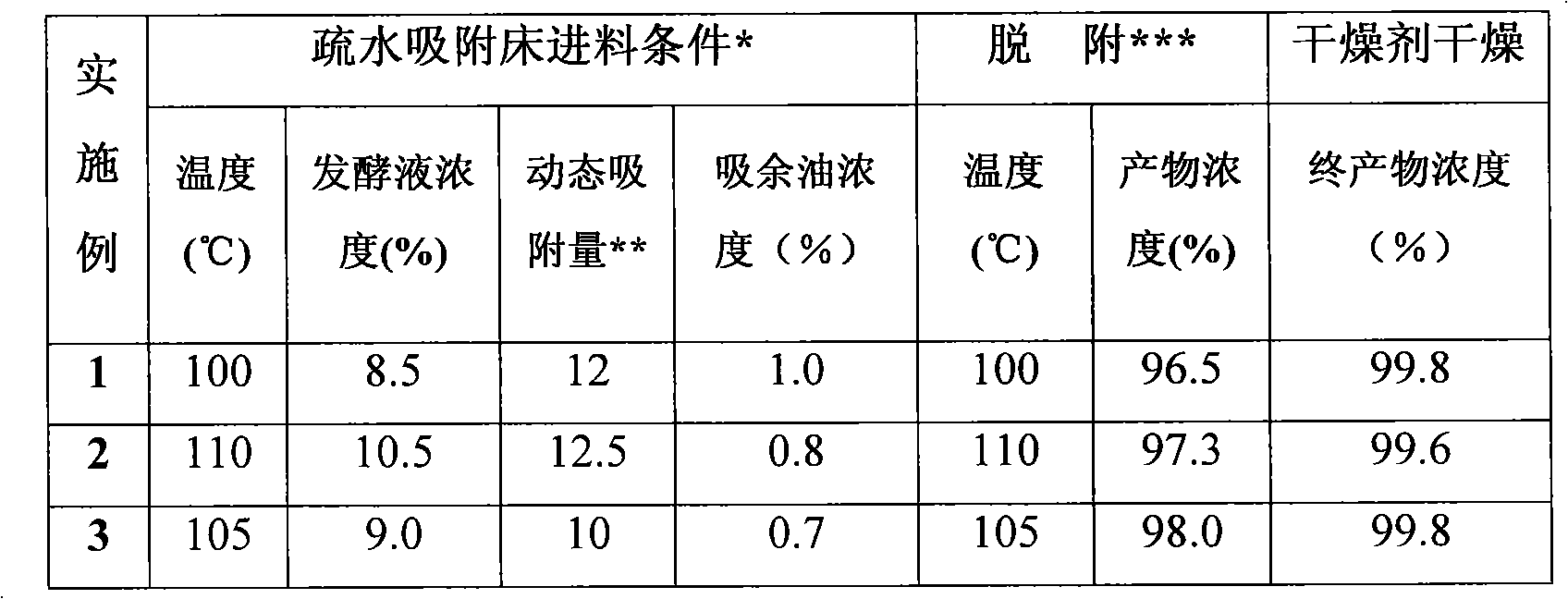

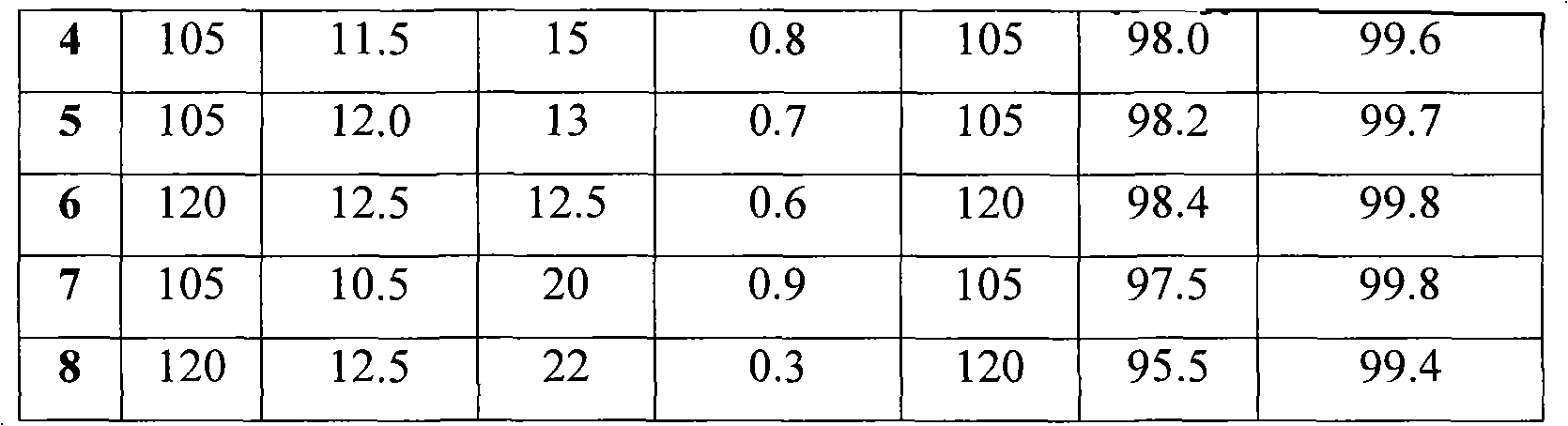

Examples

Embodiment 1

[0024] (1) chloroform content 2% temperature is the waste water solution of 25 ℃, after gas stripping or decompression, obtain the chloroform vapor of 35 ℃;

[0025] (2) After the chloroform vapor obtained in step (1) is heated to 90°C, it is passed into the first-stage adsorption bed for adsorption treatment. The adsorption bed uses 1 kg of hydrophobic silica adsorbent, and the feed rate of the chloroform vapor is 20-200g / h, the adsorption time is 45 minutes; the high-concentration chloroform with a content of more than 95% adsorbed by the hydrophobic silicalite adsorbent is desorbed by decompression desorption, the desorption temperature is 110 ° C, and the desorption time is 40 minutes.

[0026] (3) Pass the high-concentration organic vapor obtained in step (2) through the 3A adsorption bed to remove a small amount of moisture therein, and finally obtain pure chloroform with a content of 99.0%.

Embodiment 2

[0028] (1) The waste water solution with 5% isopropanol content and a temperature of 20° C. is subjected to air stripping or decompression to obtain 40° C. isopropanol vapor;

[0029] (2) after the isopropanol vapor that step (1) is obtained is heated to 115 ℃, pass into the first-stage adsorption bed, carry out adsorption treatment, the adsorption bed uses 1 kilogram of hydrophobic silica adsorbent, the feeding amount of isopropanol vapor The adsorption time is 20-200g / h, and the adsorption time is 35 minutes; the high-concentration isopropanol with a hydrophobic silicalite adsorbent content greater than 95% is desorbed by decompression desorption, the desorption temperature is 130°C, and the desorption time for 50 minutes.

[0030] (3) Pass the high-concentration organic vapor obtained in step (2) through the 3A adsorption bed to remove a small amount of moisture therein, and finally obtain pure chloroform with a content of 99.2%.

Embodiment 3

[0032] (1) The ethyl acetate content 5% temperature is the waste water solution of 20 ℃, after air stripping or decompression, obtain the ethyl acetate vapor of 40 ℃;

[0033] (2) After the ethyl acetate steam that step (1) is obtained is heated to 110 ℃, pass into the first-stage adsorption bed, carry out adsorption treatment, the adsorption bed uses 1 kilogram of hydrophobic silica adsorbent, the feeding amount of ethyl acetate steam The adsorption time is 20-200g / h, and the adsorption time is 30 minutes; the high-concentration ethyl acetate with a content greater than 95% adsorbed by the hydrophobic silicalite adsorbent is desorbed by decompression desorption, the desorption temperature is 120°C, and the desorption time is for 45 minutes.

[0034] (3) Pass the high-concentration organic vapor obtained in step (2) through the 3A adsorption bed to remove a small amount of moisture therein, and finally obtain pure chloroform with a content of 99.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com