Preparation of 5,5-diethylmalonylurea

A technology of diethylmalonylurea and crude diethylmalonylurea, which is applied in the direction of organic chemistry, etc., can solve the problems that crude mothers cannot be used mechanically, poor product appearance, cumbersome operation, etc., and achieve less three wastes and lower production costs Low, high-purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

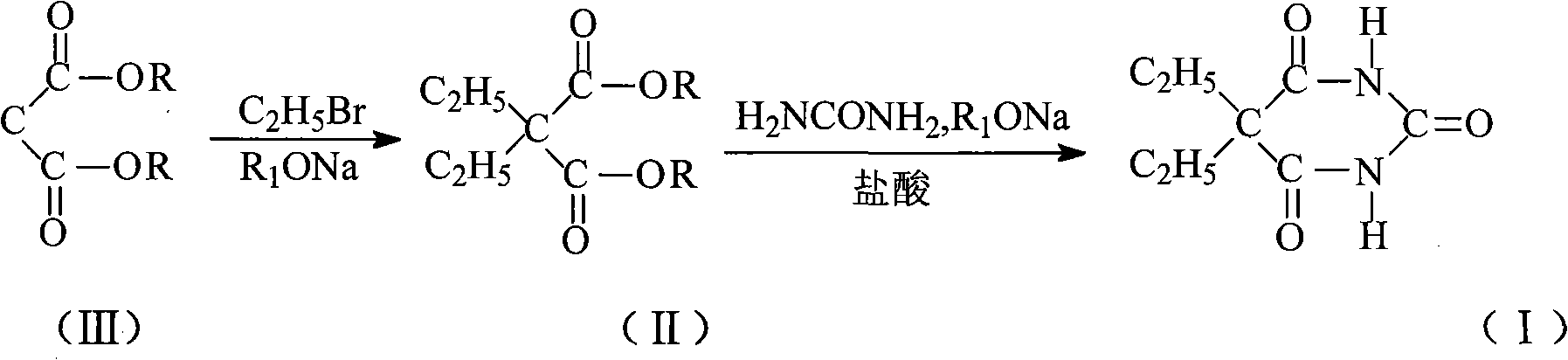

Method used

Image

Examples

Embodiment 1

[0029] Step A: adding an ethanol solution (15% by mass) containing 680 g of sodium ethylate and ethyl acetate into a reaction flask, raising the temperature to 60-65° C., and reacting for 30 minutes. Cool to below 45°C, add 800g of diethyl malonate, stir for 1 hour, add 1117g of bromoethane dropwise below 40°C. After about 7 hours of dripping, the reaction lasted for 5 hours. Gradually raise the temperature to 60-65°C for 1 hour. Ethanol and ethyl bromide were recovered by distillation to an internal temperature of 120°C. Cool down to below 40°C, and add the eliminated ethanol solution containing 84g of sodium ethoxide. Add 133g of bromoethane dropwise at below 40°C for about 4 hours, then slowly raise the temperature to 60-65°C for 1 hour. Raise the temperature and recover the solvent until the internal temperature reaches 135°C, distill the alcohol under reduced pressure when the temperature is lowered to 110°C, add water to dissolve sodium bromide when the temperature is...

Embodiment 2

[0033] Step A: Add methanol solution containing 654.2 g of sodium methoxide (25% by mass) and ethyl acetate into a reaction flask, raise the temperature to 60-65° C., and react for 30 minutes. Cool to below 45°C, add 800g dimethyl malonate, stir for 1 hour, then add 1354.3g bromoethane dropwise below 40°C. After about 7 hours of dripping, the reaction lasted for 5 hours. Gradually raise the temperature to 60-65°C for 1 hour. Recover methanol and ethyl bromide by distillation to an internal temperature of 110°C. Lower the temperature to below 40°C, add water to dissolve, statically separate the layers, evaporate the water and low boilers from the organic phase under reduced pressure to obtain a mixture of ethyl ester and heavy ester.

[0034] Add methanol solution containing 81.5g of sodium methoxide and ethyl acetate into the reaction flask, raise the temperature to 60-65°C, and react for 30 minutes. Cool to below 45°C, add the mixture of ethyl ester and heavy ester obtaine...

Embodiment 3

[0038] Step A: Add 697g of sodium ethoxide ethanol solution (20% by mass) and ethyl acetate into the reaction flask, raise the temperature to 60-65° C., and react for 30 minutes. Cool to below 45°C, add 800g of diethyl malonate, stir for 1 hour, add 1117g of bromoethane dropwise below 40°C. After about 7 hours of dripping, the reaction lasted for 5 hours. Gradually raise the temperature to 60-65°C for 1 hour. Ethanol and ethyl bromide were recovered by distillation to an internal temperature of 120°C. Lower the temperature to below 40°C, and add the eliminated ethanol solution containing 84g of sodium ethoxide. Add 133g of bromoethane dropwise at below 40°C for about 4 hours, then slowly raise the temperature to 60-65°C for 1 hour. Raise the temperature and recover the solvent until the internal temperature reaches 135°C, distill the alcohol under reduced pressure when the temperature is lowered to 110°C, add water to dissolve sodium bromide when the temperature is lowered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com