Method for producing optical film and optical film

A technology of optical film and manufacturing method, which is applied in the direction of chemical instruments and methods, optics, optical components, etc., can solve the problem of uneven drying that cannot be fully solved, and achieves the suppression of uneven drying, the stabilization of the air interface, and high display quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

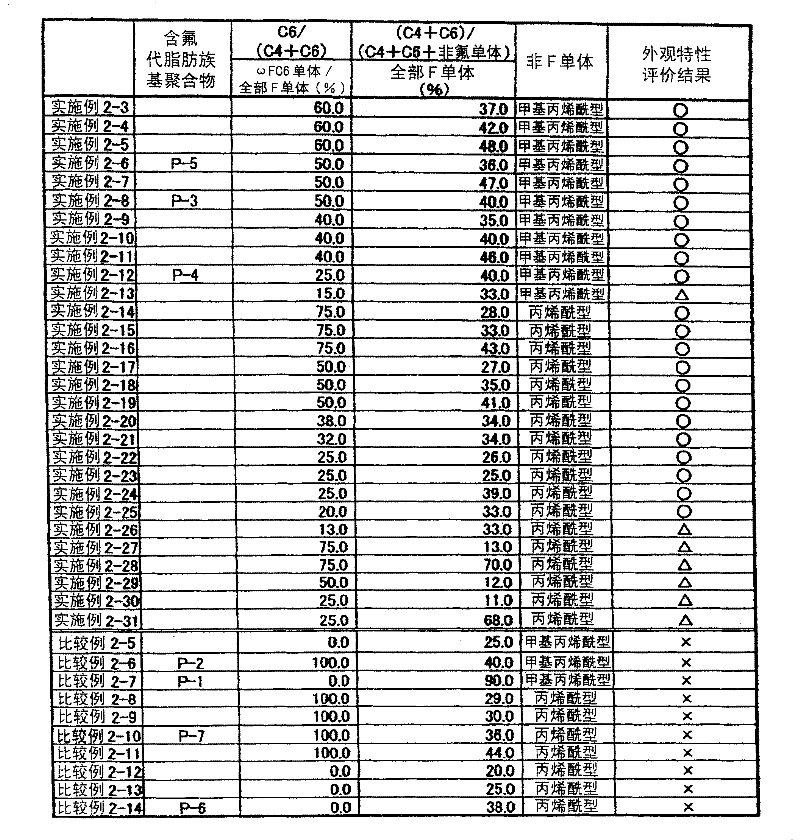

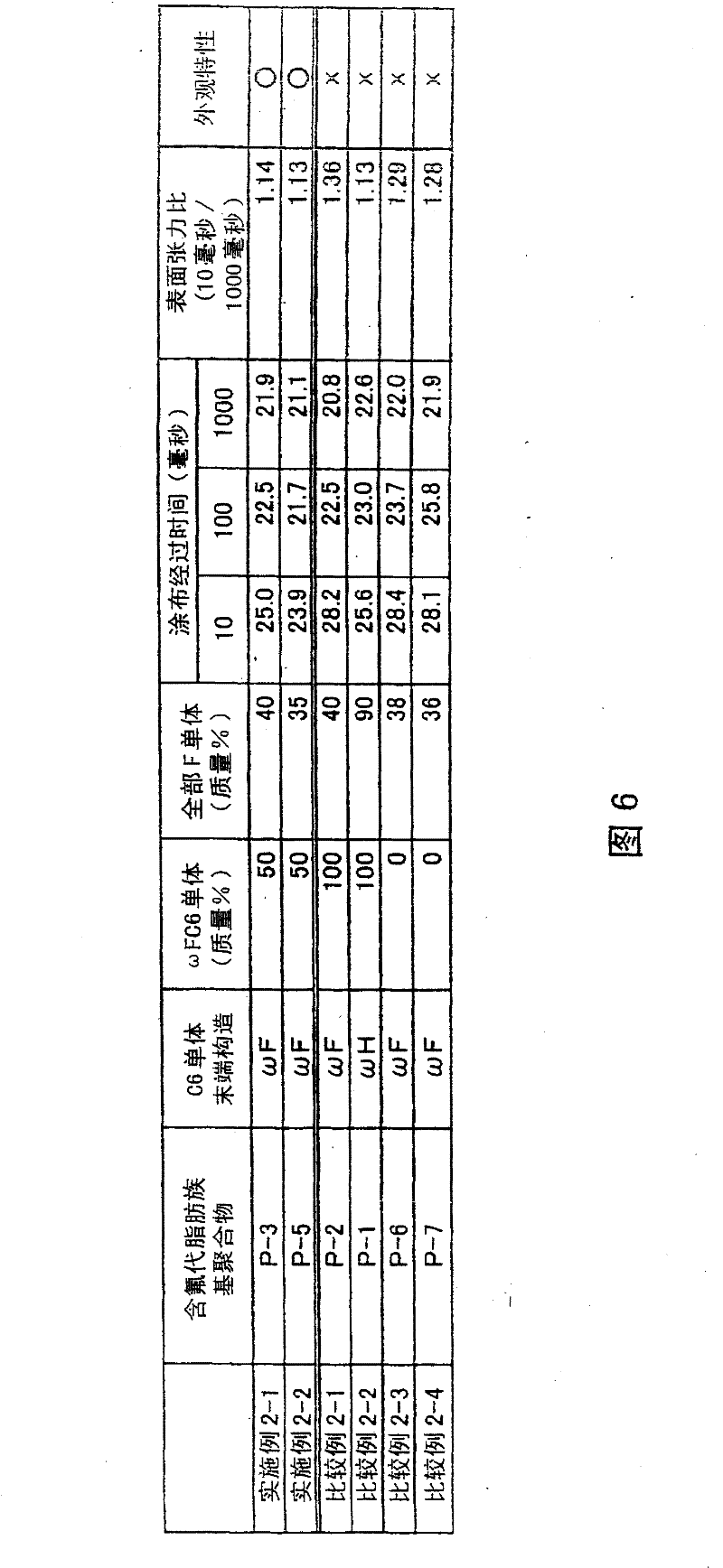

[0443] First, streaks, unevenness, and orientation of liquid crystal cells in which a fluorinated aliphatic group-containing polymer was added to a composition for forming an optically anisotropic layer were evaluated. In addition, the evaluation was performed in the same manner when the type or addition amount of the fluorinated aliphatic group-containing polymer was changed.

[0444] [Example 1]

[0445]

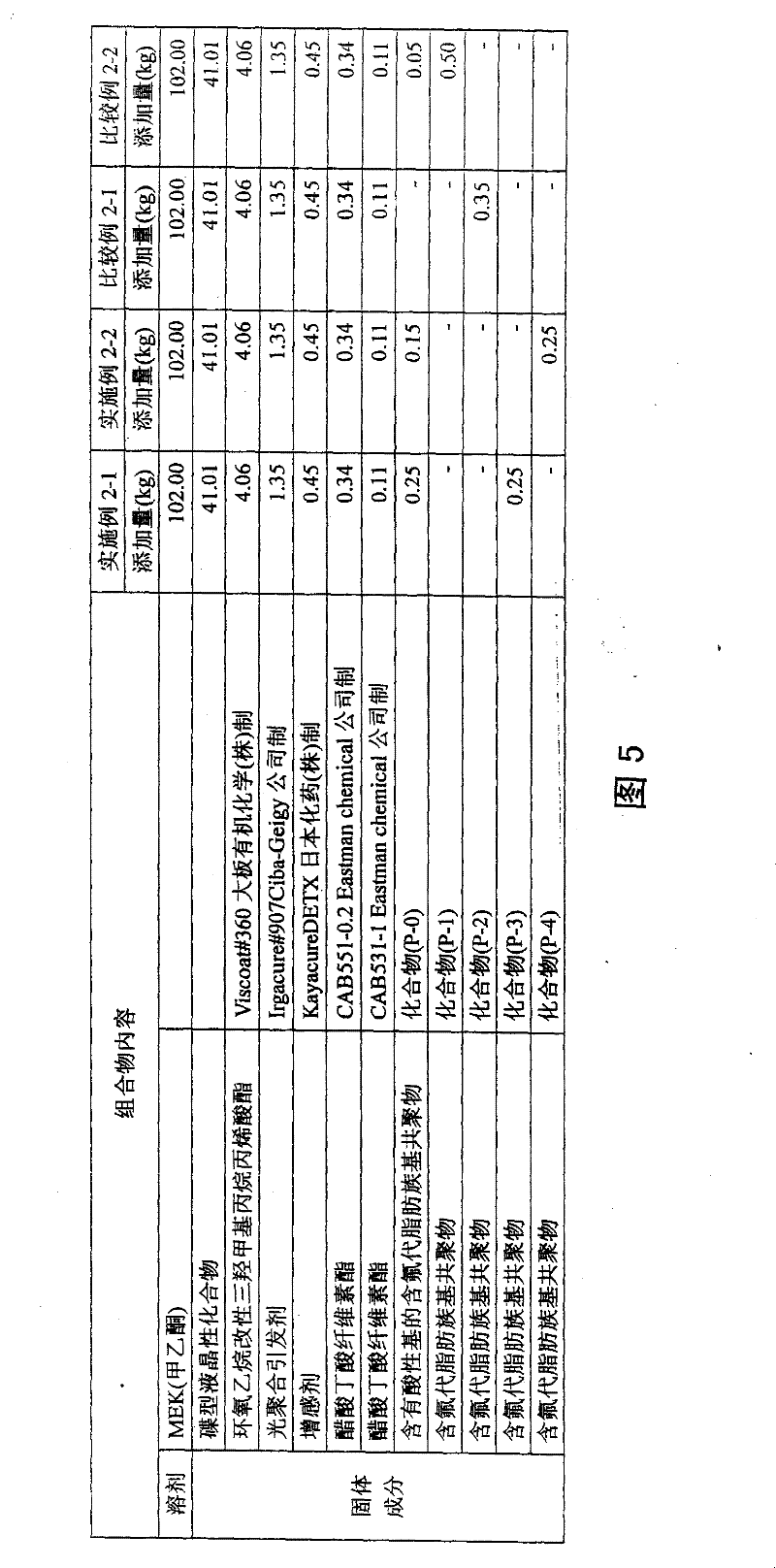

[0446] The composition described below was put into a mixing tank, stirred while heating at 30° C., and each component was dissolved to prepare a cellulose acetate solution.

[0447] Cellulose acetate solution composition (mass parts)

inner layer

outer layer

Cellulose acetate triphenyl phosphate (plasticizer) biphenyl diphenyl phosphate (plasticizer) dichloromethane (first solvent) methanol (second solvent) 1-butanol with acetylation rate of 60.9% (Third solvent) Silicon oxide microparticles (AEROSIL R972, the following retardation improving agen...

Embodiment 1-2~1-6

[0509] Except having changed coating conditions as shown in Table 1, it carried out similarly to Example 1-1.

[0510] The results are shown in Table 2.

Embodiment 1-7~1-13

[0520] Next, the coating amount of 6.4mL / m was evaluated 2 , drying speed 1.06g / (m 2 • seconds) is constant, and the effect on the surface state and optical properties of the optical compensation sheet when the added amount of the fluorinated aliphatic group-containing polymer is changed. The results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com