Method for preparing compound microbial preparation for degrading í«three-benzeneí» VOCs exhaust air

A technology of compound microbial bacterial agent and triphenyl, which is applied in the field of preparation of compound microbial bacterial agent, can solve the problem that the compound microbial bacterial agent has not yet been retrieved, and achieve the effect of being more conducive to long-term storage, prolonging the service life, and enriching the microbial population

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

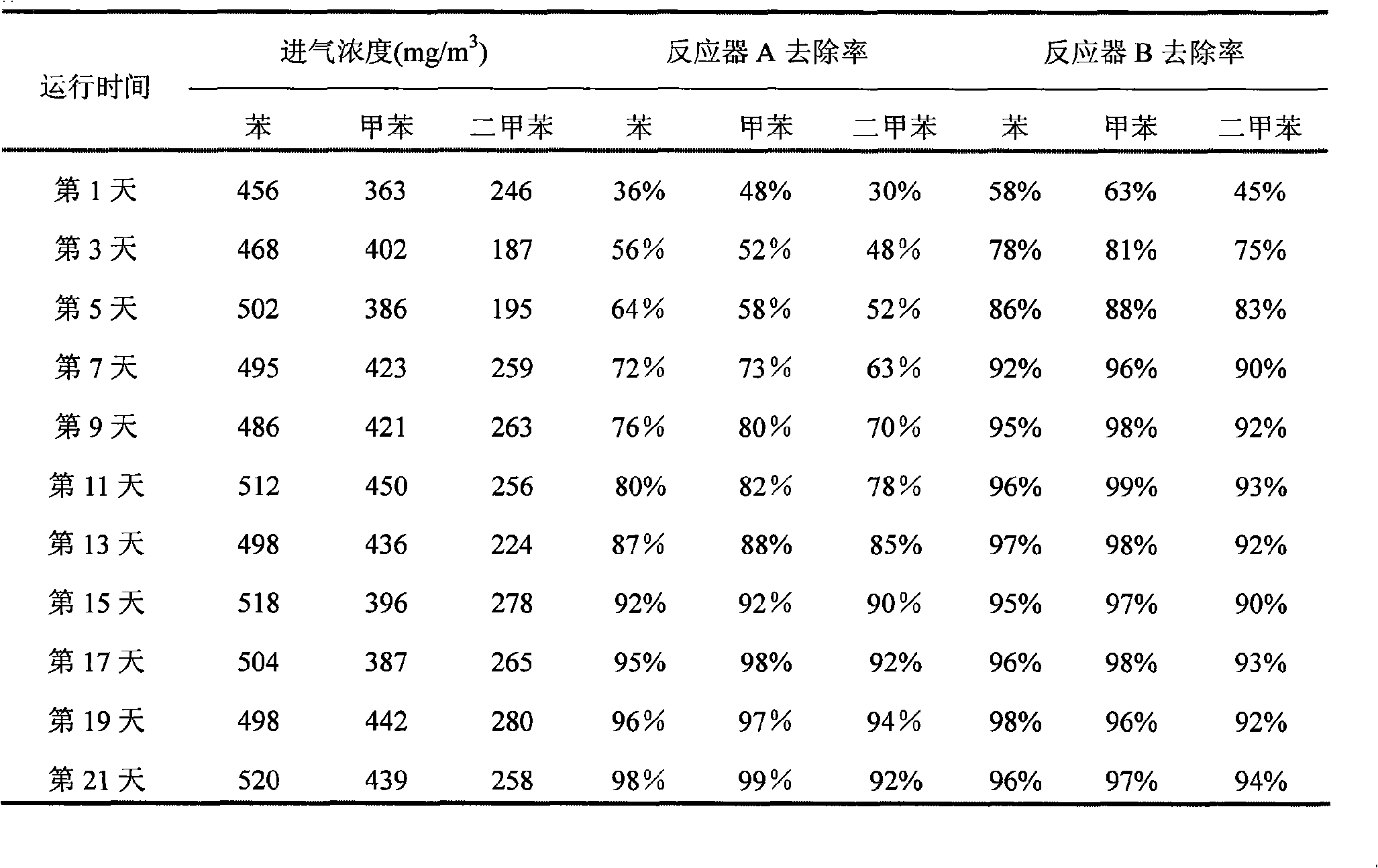

Examples

Embodiment 1

[0019] (1) Sample collection: Activated sludge was taken from the aeration tank of a sewage plant, stored in a refrigerator at 4°C, and used within 48 hours.

[0020] (2) Activated sludge acclimation medium: 800mg / L benzene, 500mg / L toluene, 300mg / L o-xylene, K 2 HPO 4 2.0mg / L, Na 2 HPO 4 5.0mg / L, KH 2 PO 4 1.5mg / L, NH 4 Cl4.5mg / L, MgSO 4 6.5mg / L, 4.0mg / L CaCl 2 , 0.25mg / L FeCl 3 , MnSO 4 0.05mg / L, ZnSO 4 0.01mg / L, (NH 4 ) 6 Mo 7 o 24 4H 2 O 0.01mg / L.

[0021] (3) Activated sludge acclimation method: Settling the fresh sludge for 30 minutes, taking 50ml of thick sludge into a 500ml Erlenmeyer flask, and adding 100ml of acclimation medium. The Erlenmeyer flask was placed in a shaker at 28°C and 160 rpm for shaking culture. Every 5 days was an acclimatization cycle, and the pH of the acclimatization system was measured every other day in a cycle, and adjusted to 6.0-8.0. After the end of each cycle, replace the fresh medium and add the same concentration of trip...

Embodiment 2

[0026] (1) Sample collection: Same as Example 1.

[0027] (2) Activated sludge acclimation medium: benzene 1000mg / L, toluene 1000mg / L, o-xylene 500mg / L, K 2 HPO 4 6.0mg / L, Na 2 HPO 4 8.0mg / L, KH 2 PO 4 4.0mg / L, NH 4 Cl6.0mg / L, MgSO 4 8.5mg / L, 8.0mg / L CaCl 2 , 1.0mg / L FeCl 3 , MnSO 4 0.5mg / L, ZnSO 4 0.1mg / L, (NH 4 ) 6 Mo 7 o 24 4H 2 O 0.1mg / L.

[0028] (3) Activated sludge domestication method: with embodiment 1.

[0029] (4) Preparation of bacterial agent carrier: wheat bran, mahogany chips and diatomaceous earth are mixed by 85%: 10%: 5%, and water is added in the amount of carrier: water (adjusted to 7) according to the amount of carrier: water (pH is adjusted to 7), after mixing Divide, add 50 grams of carrier to each 500ml Erlenmeyer flask, sterilize with damp heat at 121°C for 30 minutes, then cool down for use.

[0030] (5) Preparation process of compound microbial bacterial agent: inoculate 10ml of domesticated mixed strains in the carrier prepared in ...

Embodiment 3

[0033] (1) Sample collection: Same as Example 1.

[0034] (2) Activated sludge acclimation medium: 800mg / L benzene, 800mg / L toluene, 400mg / L o-xylene, K 2 HPO 4 4.0mg / L, Na 2 HPO 4 6.5mg / L, KH 2 PO 4 4.0mg / L, NH 4 Cl5.0mg / L, MgSO 4 7.0mg / L, 6.0mg / L CaCl 2 , 0.7mg / L FeCl 3 , MnSO 4 0.2mg / L, ZnSO 4 0.05mg / L, (NH 4 ) 6 Mo 7 o 24 4H 2 O 0.03mg / L.

[0035] (3) Activated sludge domestication method: with embodiment 1.

[0036] (4) Bacteria agent carrier preparation: wheat bran, cellulose and stabilizer are mixed by 80%: 15%: 5%, add water (pH is adjusted to 8) according to the amount of carrier: water is 1: 2, divide after mixing For each 500ml Erlenmeyer flask, add 50 grams of carrier, sterilize with damp heat at 121°C for 30 minutes, and then cool it down for use.

[0037] (5) Preparation process of compound microbial bacterial agent: inoculate 15ml of domesticated mixed strains in the carrier prepared in the above (2), solid fermentation culture at 45°C for 48h,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com