Lignose alcohol ether carboxylate surfactant and preparation method thereof

A technology of alcohol ether carboxylate and surfactant, which is applied in the field of surfactant preparation, can solve the problems that the preparation method of alcohol ether carboxylate surfactant has not been reported, so as to change serious environmental pollution and make full use of resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Preparation of lignin alcohol ether:

[0034] In the first step, take 100 parts by mass of purified lignin with a mass fraction of lignin above 95%, 0.1 to 5 parts by mass of catalyst NaOH, 20 to 100 parts by mass of toluene as a solvent, and react in an oxygen-free environment at a reaction temperature of 80 to 150°C. The reaction pressure is 0.3-1.0 MPa, stirring, and dividing 10-100 mass parts of ethylene oxide and 10-100 mass parts of propylene oxide into 2-10 groups;

[0035] In the second step, after passing through one group of ethylene oxide each time and reacting for 30-60 minutes, then passing through one group of propylene oxide and reacting for 30-60 minutes;

[0036] The third step, repeat the second step, until all ethylene oxide and propylene oxide have reacted, stop the reaction and stop heating, stop stirring after cooling to room temperature, add inert gas to 1 atmospheric pressure, and then distill under reduced pressure, The low boiling fraction is ...

Embodiment 1

[0038] The preparation method of lignin alcohol ether carboxylate is prepared by the following steps:

[0039] 100 parts by mass of lignin alcohol ether and an alkali catalyst whose amount is 1 to 1.2 times that of lignin alcohol ether are reacted at 90 to 110°C for 30 to 60 minutes, and low boiling point substances are removed under reduced pressure at -0.1MP. Add the halogenated acid whose amount is 1.2-1.5 times of the lignin alcohol ether, and react for 4-8 hours to obtain the lignin alcohol ether carboxylate.

[0040] Wherein the alkali catalyst can be 1, 1.1, 1.2 times of the amount of the lignin alcohol ether, the reaction temperature can be 90°C, 100°C, 110°C, the reaction time can be 30min, 45min, 60min, and the amount of the halogenated acid can be It is 1.2 times, 1.35 times, 1.5 times, and the reaction time can be 4h, 5.5h, 8h. The halogenated acid can be any one of 2-chloropropionic acid, monochloroacetic acid, 2-bromopropionic acid, and bromoacetic acid; the bas...

Embodiment 2

[0042] The preparation method of lignin alcohol ether carboxylate:

[0043] Add 100 parts by mass of lignin alcohol ether, add catalyst NaOH in an amount 1.2 times the amount of lignin alcohol ether, react at 90-100°C for 30 minutes, remove water under reduced pressure, and mix lignin alcohol ether and monochloroacetic acid Chloroacetic acid was added dropwise at a molar ratio of 1:1.2, and reacted for 4 hours to obtain sodium lignin alcohol ether carboxylic acid. Sampling was carried out to determine the hydroxyl value of lignin alcohol ether carboxylic acid sodium salt to be 40 mg / g.

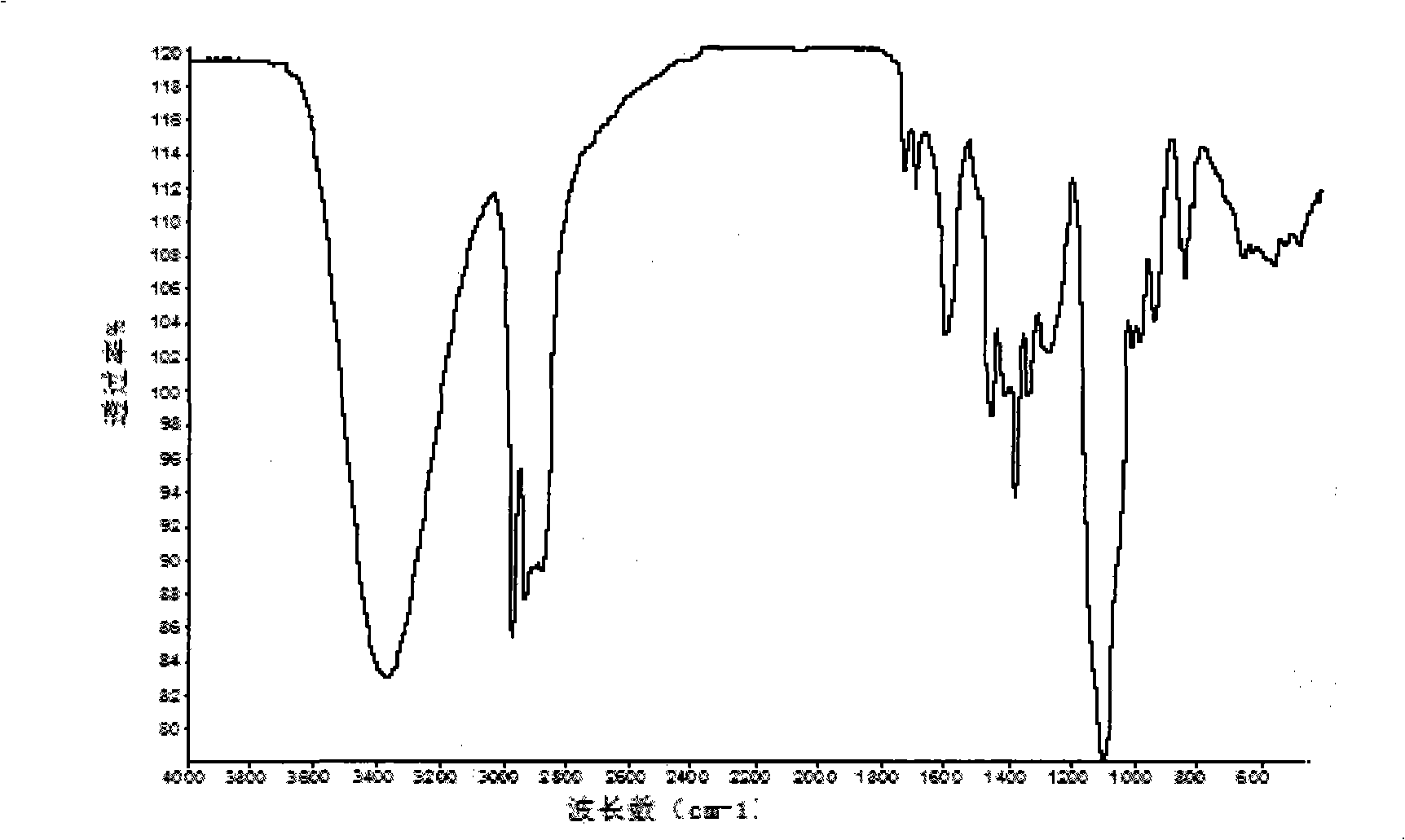

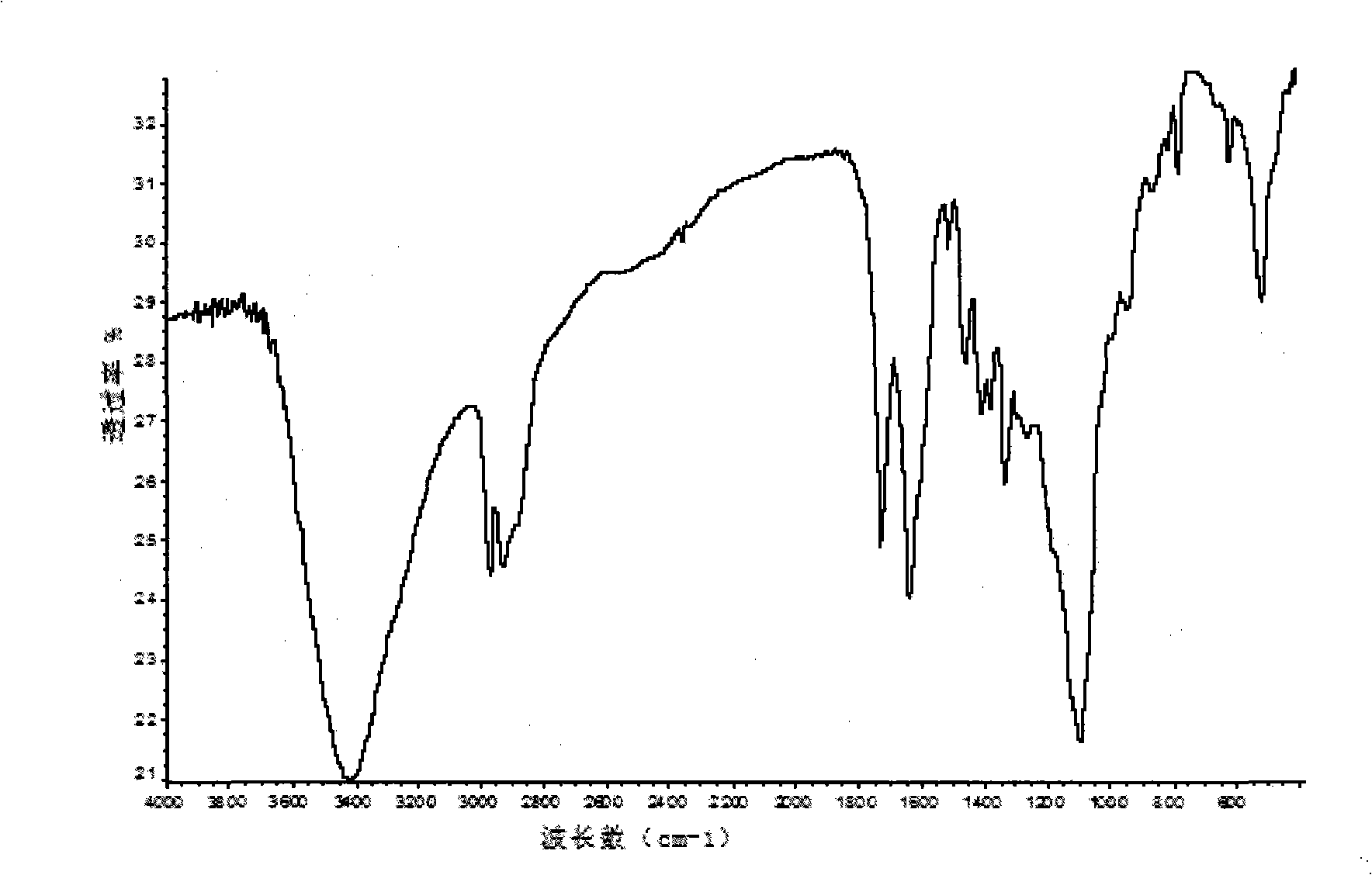

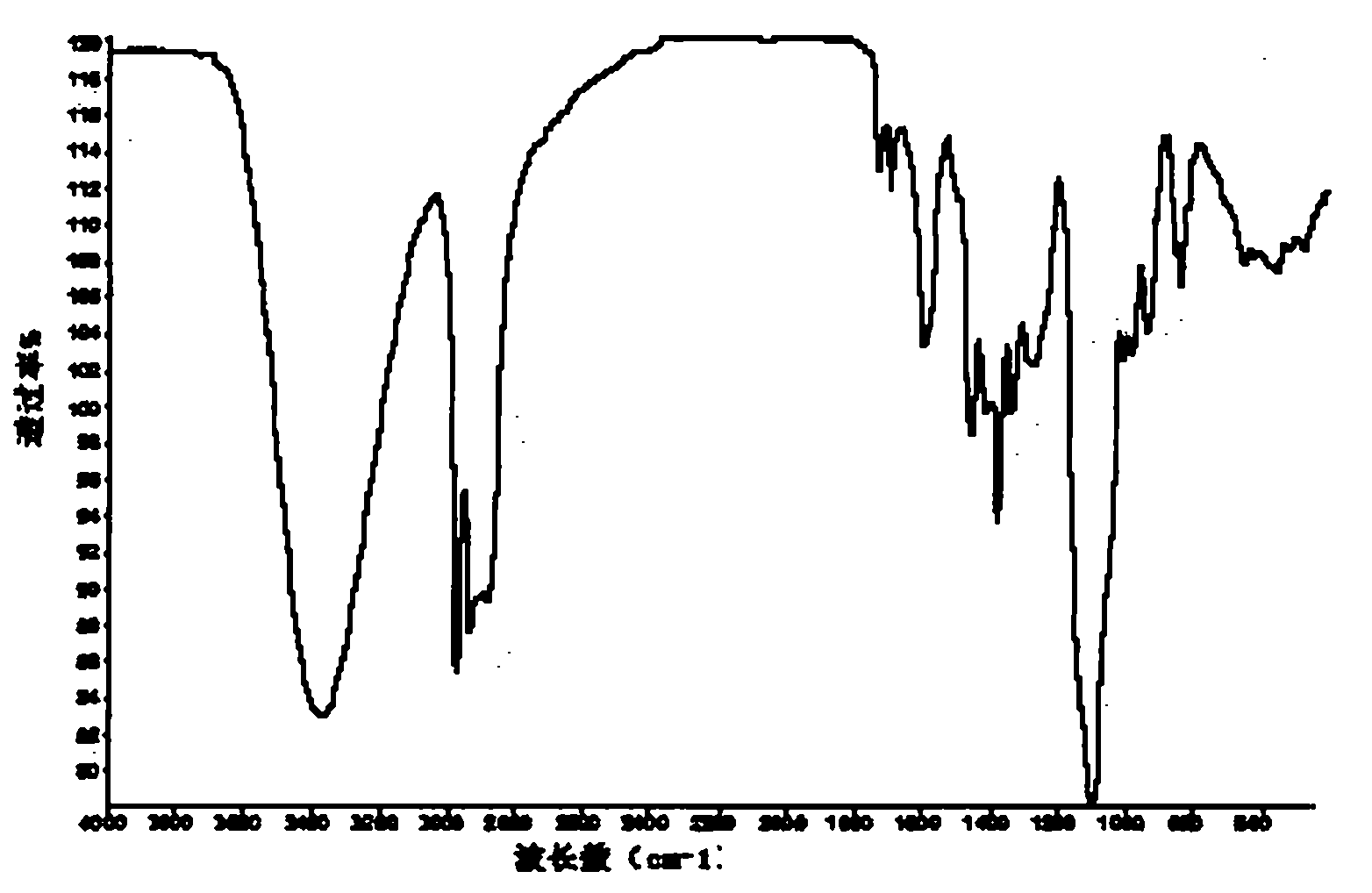

[0044] Comparison of IR spectrum analysis of lignin alcohol ether carboxylic acid sodium salt IR and raw material lignin alcohol ether: at 3700cm -1 ~3030cm -1 The absorption decreases, indicating that the hydroxyl group in the lignin alcohol ether is reacted, resulting in 3418.18cm -1 Absorption decreases. . at 1096.25cm -1 The intensity of the absorption peak at 1726.65cm decreases, in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com