High-efficient regeneration method for preparing low carbon olefins catalyst from oxygen-containing compounds

A high-efficiency regeneration and low-carbon olefin technology, applied in the direction of hydrocarbon production from oxygen-containing organic compounds, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve problems such as temperature fluctuations in regenerators, achieve short residence time, and improve carbon-based utilization rate, the effect of low oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

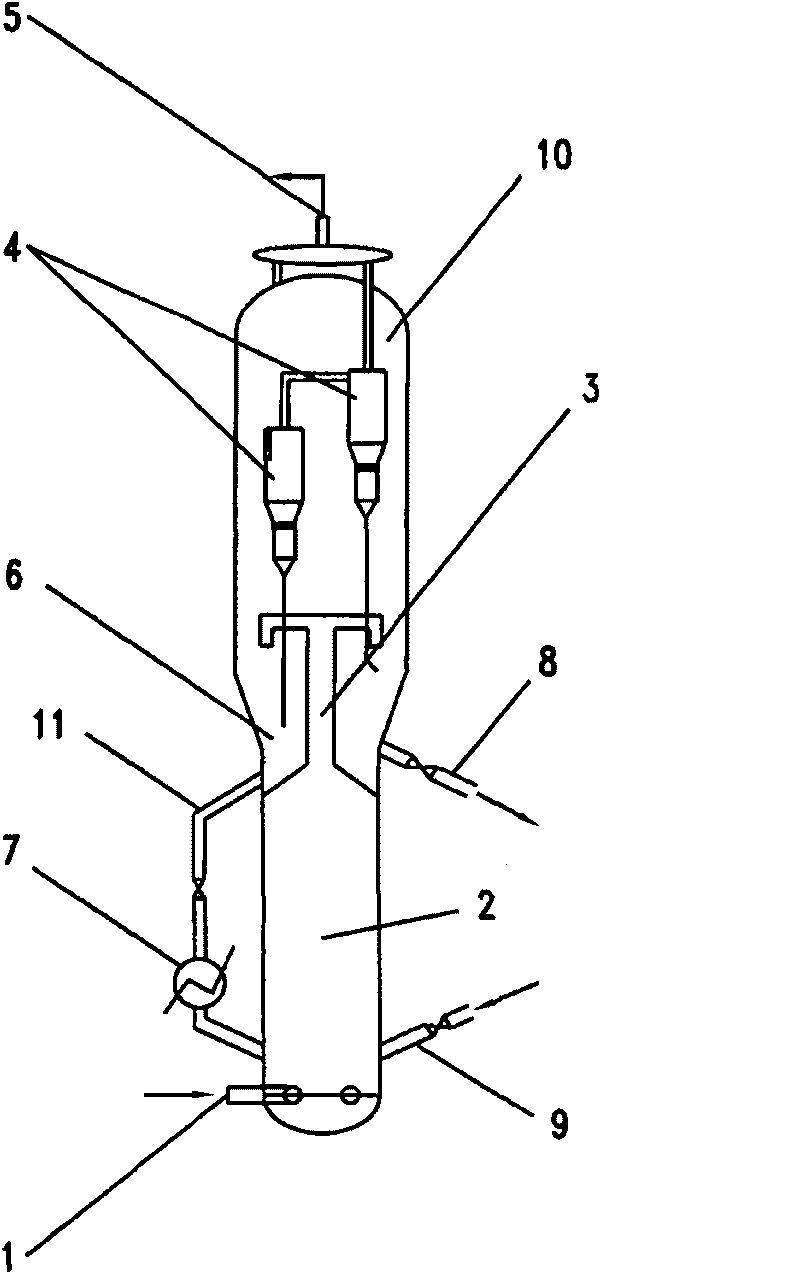

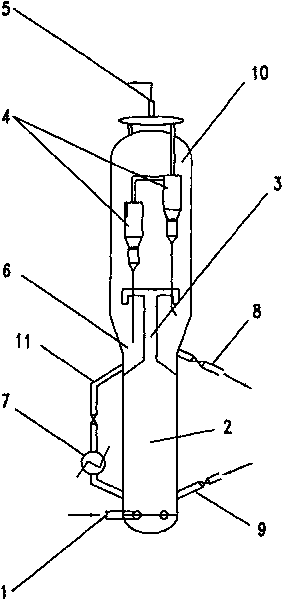

[0017] exist figure 1 In the small fast fluidized bed regenerator shown, the catalyst is SAPO-34 molecular sieve, the amount of coke deposited on the ungenerated catalyst belt is 4.5% by weight, the regeneration temperature is set at 700°C, the regeneration medium is air, and the degassing medium is nitrogen. The temperature of the regeneration medium is 300°C, the linear velocity of the gas phase in the regeneration zone is 1.3 m / s, the weight ratio of the first part of the catalyst to the second part of the catalyst is 2:1, the temperature of the dense phase of the regeneration and the flow rate of the fluidized medium of the external heat extractor of the regenerator Automatic cascade control is adopted, the fluidization medium of the heat extractor outside the regenerator is nitrogen, the heat exchange medium is water, and the diameter of the high-efficiency regeneration zone is 1 / 6 of the diameter of the regeneration zone. The continuous operation results for three hours s...

Embodiment 2

[0019] exist figure 1 In the small fast fluidized bed regenerator shown, the catalyst is SAPO-34 molecular sieve, the amount of coke deposited on the ungenerated catalyst belt is 1.5% by weight, the regeneration temperature is set at 600°C, the regeneration medium is air, and the degassing medium is nitrogen. The temperature of the regeneration medium is 100°C, the linear velocity of the gas phase in the regeneration zone is 0.8 m / s, the weight ratio of the first part of the catalyst to the second part of the catalyst is 2:1, the temperature of the dense phase of the regeneration and the flow rate of the fluidized medium of the external heat extractor of the regenerator Automatic cascade control is adopted, the fluidization medium of the heat extractor outside the regenerator is nitrogen, the heat exchange medium is water, and the diameter of the high-efficiency regeneration zone is 1 / 4 of the diameter of the regeneration zone. The continuous operation results for three hours s...

Embodiment 3

[0021] exist figure 1 In the small fast fluidized bed regenerator shown, the catalyst is SAPO-34 molecular sieve, the amount of coke deposited on the ungenerated catalyst belt is 0.5% by weight, the regeneration temperature is set at 600°C, the regeneration medium is air, and the degassing medium is nitrogen. The temperature of the regeneration medium is 100°C, the linear velocity of the gas phase in the regeneration zone is 0.8 m / s, the weight ratio of the first part of the catalyst to the second part of the catalyst is 0.8:1, the temperature of the dense phase of the regeneration and the flow rate of the fluidized medium of the heat extractor outside the regenerator Automatic cascade control is adopted, the fluidization medium of the heat extractor outside the regenerator is nitrogen, the heat exchange medium is water, and the diameter of the high-efficiency regeneration zone is 1 / 6 of the diameter of the regeneration zone. The continuous operation results for three hours sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com