Method and apparatus for removing superadiabatic partial oxidation coke tar and coke and gas reform

A technology of tar coke and super-insulation, which is applied to the processing of chemical instruments and methods, catalyst carriers, and gas mixtures, etc., can solve problems affecting the catalytic performance and effect of catalysts, expensive production costs of catalysts, and small specific surface areas of catalysts. Remarkable reaction selectivity, compact structure, and prolonged catalyst life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

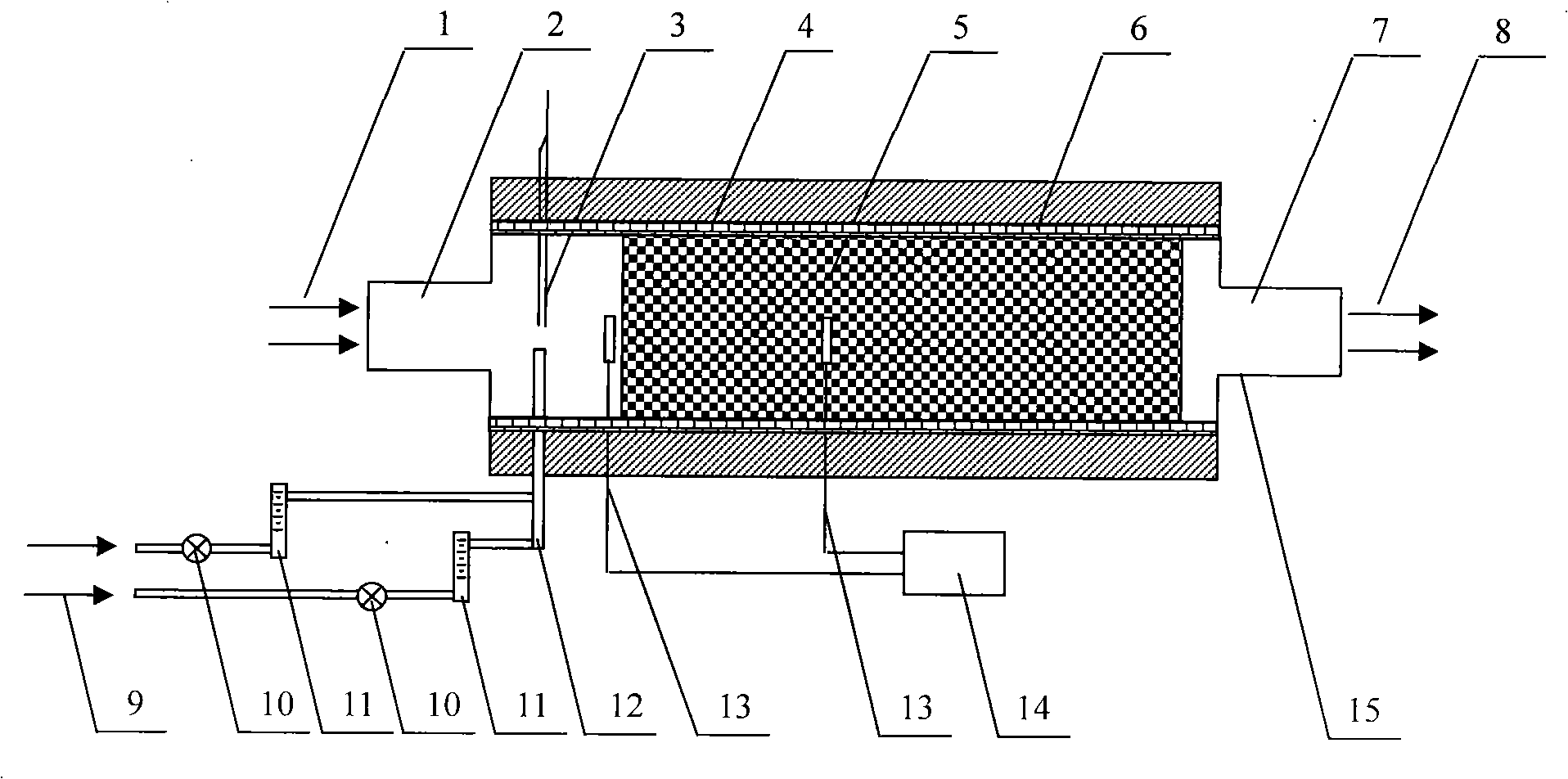

[0019] A super-insulated partial oxidation tar coke removal and combustible gas reforming device of the present invention will be described in detail below in conjunction with the technical scheme and accompanying drawings.

[0020] The super-insulated partially oxidized tar coke removal and combustible gas body reforming device of the present invention is composed of a common porous ceramic body or a porous ceramic catalyst as the filler of stainless steel tube 15, a gas source supply device and a refractory material furnace tube device. The stainless steel tube 15 is built in the refractory material furnace tube 6, and the outer layer of the refractory material furnace tube 6 is wrapped by the insulation layer 4 for heat preservation, and ordinary porous ceramics or porous ceramic catalyst 5 are used as fillers to be placed in the stainless steel tube 15 pipeline. A combustion nozzle 12 is arranged at the front end or inside of the porous ceramic, and the oxygen or reforming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com