Free-piston type internal combustion engine

A piston type, internal combustion engine technology, applied in automatic control, automatic control, electrical automatic control and other directions, can solve the problems of poor economy, power performance, deterioration of engine performance, inability to flexibly adjust the ignition position, etc., to ensure safe operation, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

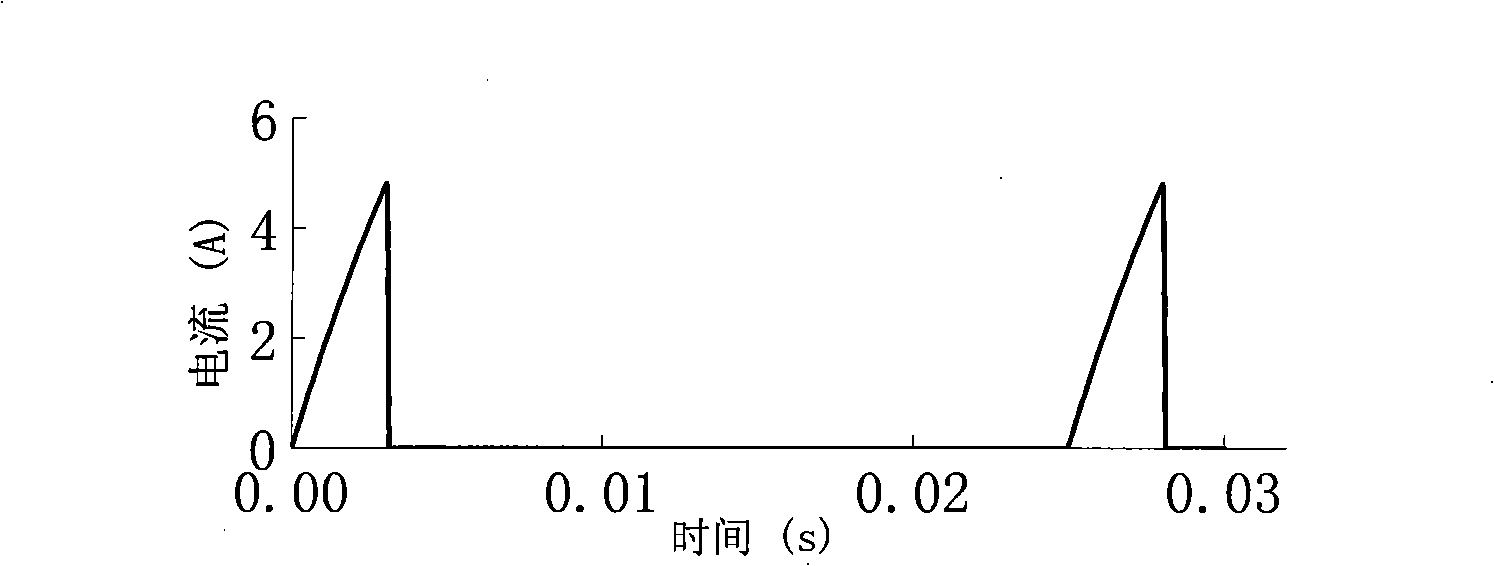

[0052] Example Simulation

[0053] The cost of computer simulation is low, and it can reflect the research object more accurately. For the ignition system proposed by the present invention, through simulation modeling, different working processes of the ignition system under normal and abnormal conditions can be investigated, which is conducive to further understanding the characteristics of the ignition system.

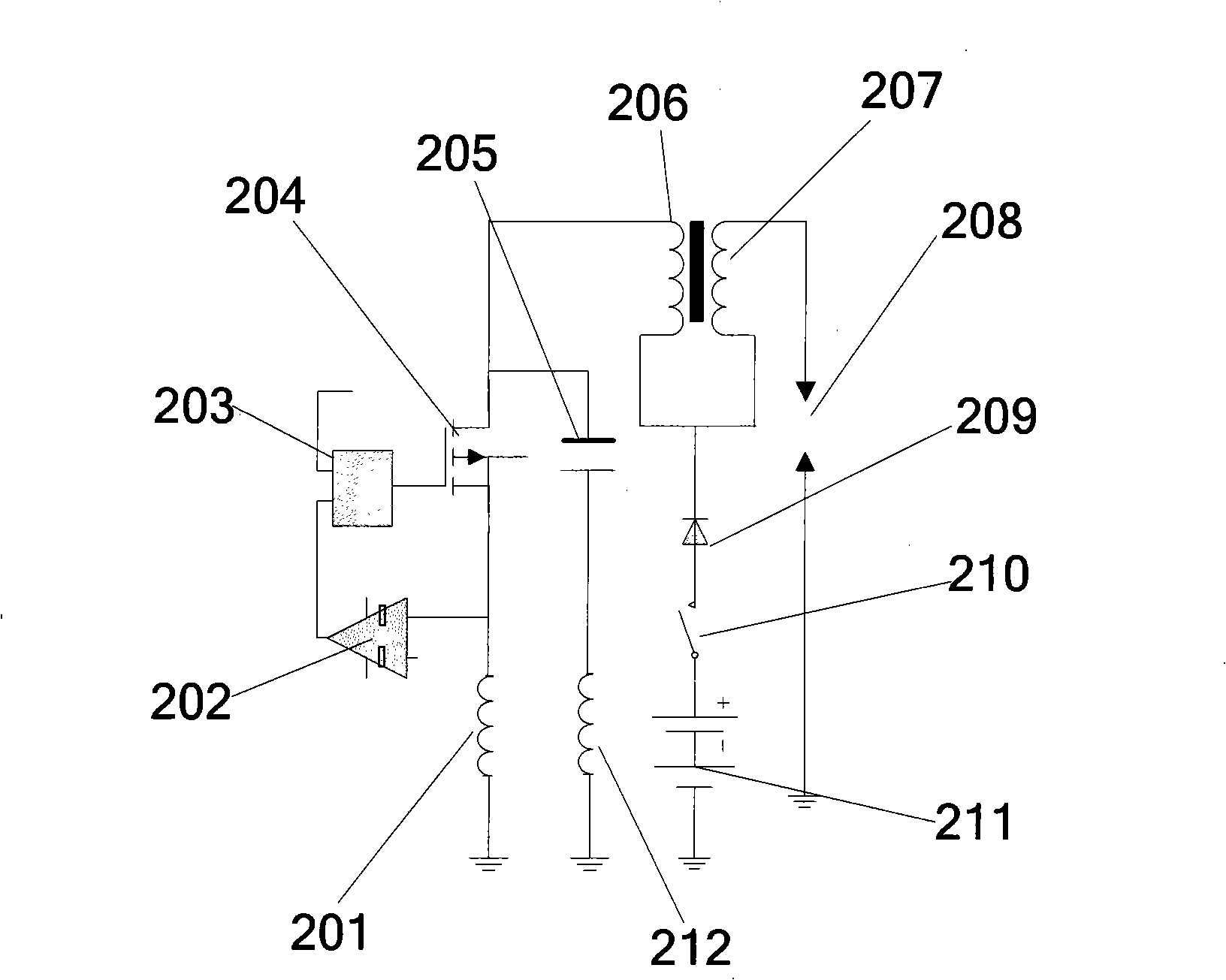

[0054] (1).Simulation of normal ignition

[0055] High-energy ignition coil parameters: primary winding 0.55Ω, inductance 5.8mH; secondary winding 6.2kΩ, inductance 14H; energy conversion efficiency 75%, sampling resistance 0.1Ω. According to the calculation, the time constant of the primary circuit in this design scheme is about 8.9ms. Under this charging time, the primary cut-off current can reach more than 10A without limitation. Not using current limiting control not only wastes electric energy, but also may damage the circuit. Using Matlab / Simulink to program,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com