Method of preparing lithium ion battery negative pole carbon material

A lithium ion battery and a manufacturing method technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of reducing battery capacity and cycle life, unfavorable lithium ion deintercalation, reducing battery safety, etc., to achieve increased area, The effect of improving battery safety and cyclability and increasing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] 1. Manufacture of negative electrode carbon materials for lithium-ion batteries

[0012] Dissolve coal tar pitch or petroleum pitch in gasoline at a blending ratio of 20% to 80%, and remove insoluble components in it by rapid solidification and dilution; put the pitch at a temperature of 400°C to 700°C in N2 or Ar gas Heat treatment in the atmosphere for 3 to 30 hours to fully carbonize the pitch and pulverize the carbonized pitch; heat the pulverized carbonized pitch at 2000 to 3000°C for 5 to 30 hours in a N2 or Ar gas atmosphere, and then pulverize Graphitization of asphalt, the graphitized pitch is dissolved in hydrogen peroxide at a ratio of 10% to 60%, and sintered at 80 to 300°C for 2 to 50 hours in an oxygen atmosphere to obtain porous layered high-capacity carbon Negative material.

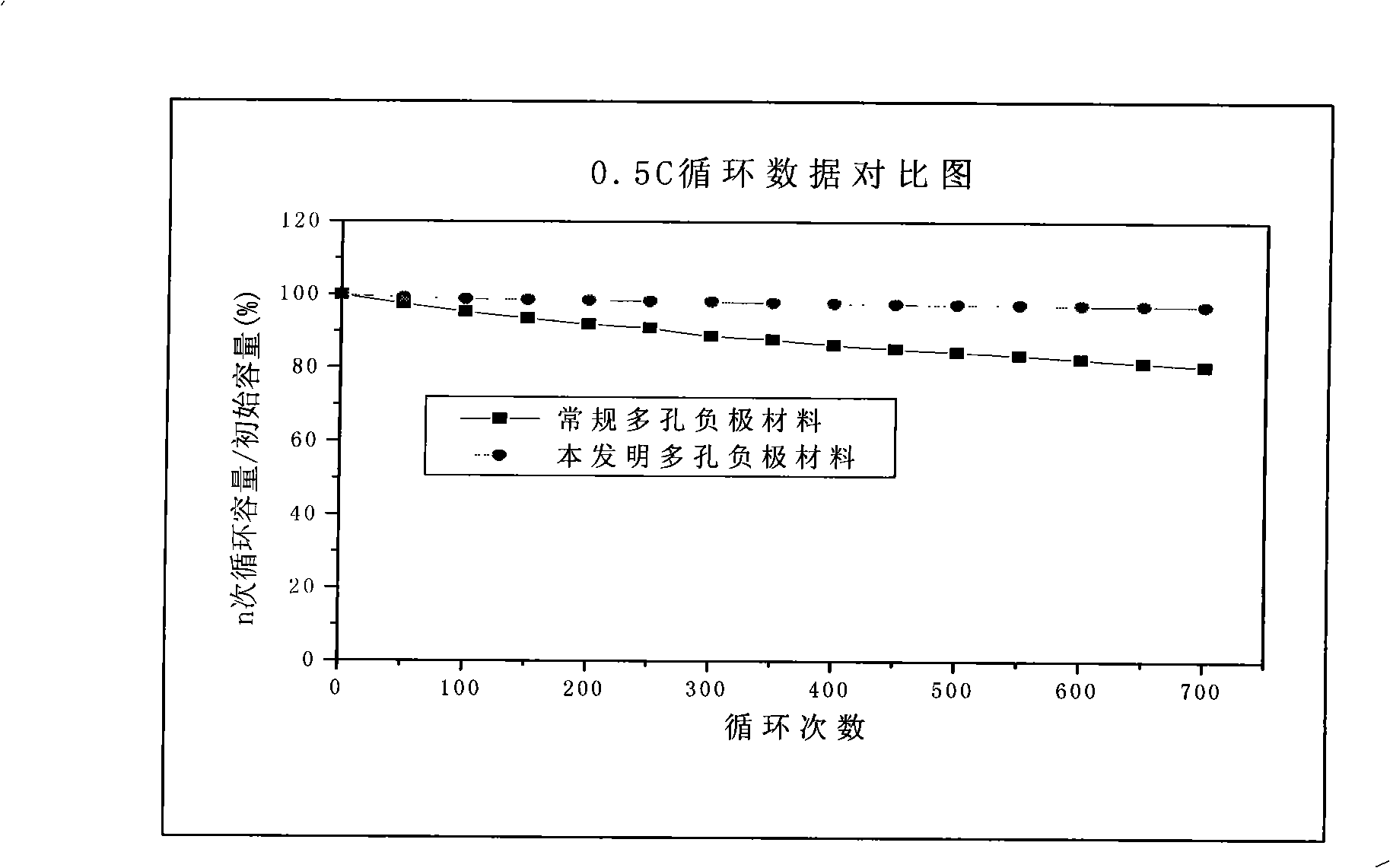

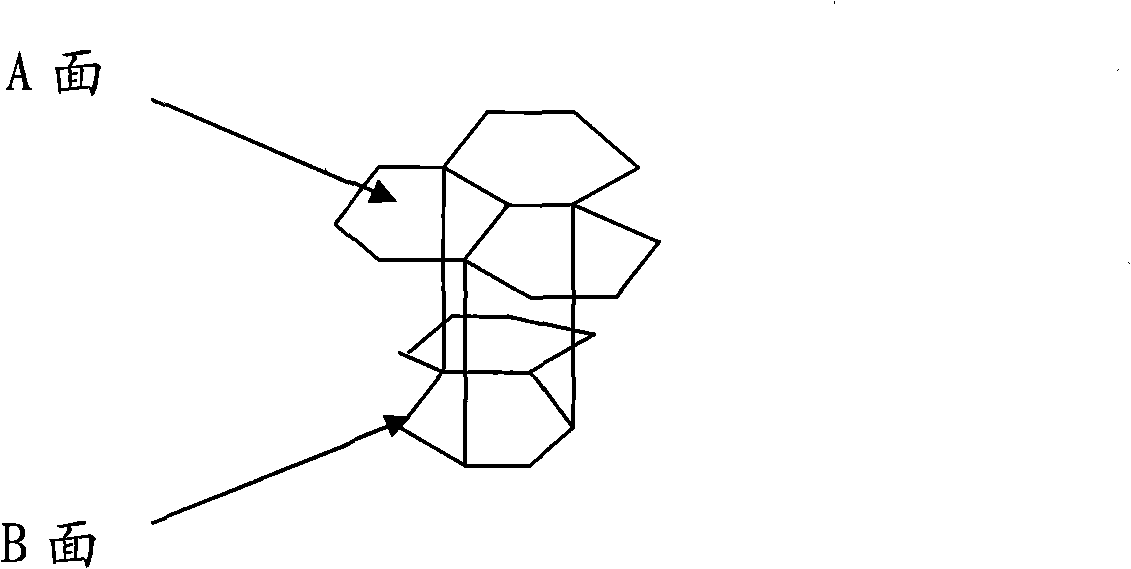

[0013] The porosity range of the lithium ion battery negative electrode carbon material provided by the present invention is 30%-50%. Such a large porosity determines that the eff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com