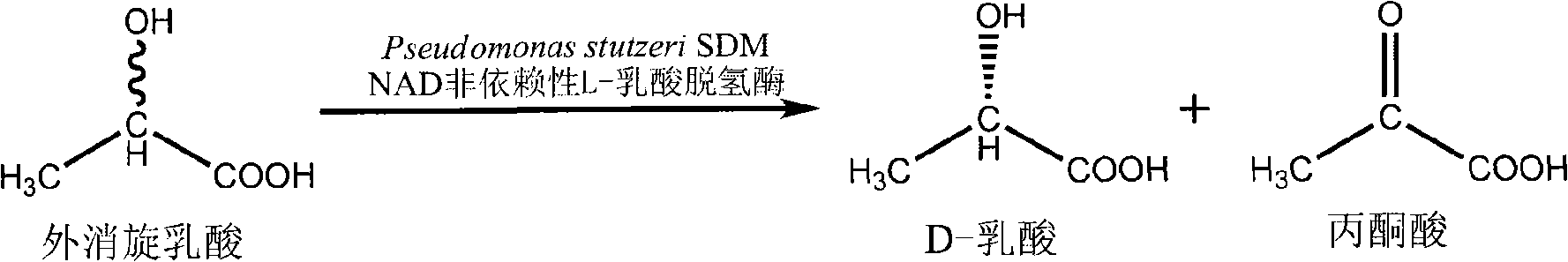

Method for producing D-lactic acid by enzyme resolution of D,L-lactic Acid

A lactic acid and enzymatic technology, applied in the field of preparation of D-lactic acid, to achieve the effects of high substrate concentration, high substrate conversion rate and short growth cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: The method of using P.stutzeri SDM crude enzyme liquid to resolve racemic lactic acid to produce D-lactic acid

[0040] (1) Preparation of crude enzyme solution containing NAD-independent lactate dehydrogenase: select Pseudomonas stutzeri (Pseudomonasstutzeri) SDM CCTCC No.M206010 bacterial strain (the applicant of the bacterial strain has been preserved in China Center for Type Culture Collection) were inoculated on solid slant basic medium containing 1.5% agarose and added with 0.5% DL-sodium lactate, and cultured at 30°C for 20 hours. Put the above-mentioned cultured strains into 50 ml of liquid basic medium containing 0.5% DL-sodium lactate with an inoculation loop and inoculate 1 to 2 loops under aseptic conditions, and culture it on a shaker at 180 rpm for 10 hours at 30°C. , to produce seeds;

[0041] With a 5% (volume ratio) inoculum size, the inoculum was placed in 150 ml of liquid basic medium containing 1% DL-sodium lactate, and cultured on a shak...

Embodiment 2

[0048] Example 2: The method of using P. stutzeri SDM crude enzyme solution to resolve racemic lactic acid to produce D-lactic acid

[0049] (1) Preparation of crude enzyme solution containing NAD-independent lactate dehydrogenase: select Pseudomonas stutzeri (Pseudomonasstutzeri) SDM CCTCC No.M206010 strain to inoculate in 1.5% agarose containing 0.5% DL- Sodium lactate solid slant minimal medium, cultured at 30°C for 20 hours. Put the above-mentioned cultured strains into 50 ml of liquid basic medium containing 0.5% DL-sodium lactate with an inoculation loop and inoculate 1 to 2 loops under aseptic conditions, and culture it on a shaker at 180 rpm for 10 hours at 30°C. , to produce seeds;

[0050] With a 5% (volume ratio) inoculum size, the inoculum was placed in 150 ml of liquid basic medium containing 1% DL-sodium lactate, and cultured on a shaker at 30°C until the enzyme activity of NAD-independent lactate dehydrogenase reached 220 units / liter, stop the fermentation cul...

Embodiment 3

[0057] Example 3: The method of using P.stutzeri SDM crude enzyme liquid to resolve racemic lactic acid to produce D-lactic acid

[0058] (1) Preparation of crude enzyme solution containing NAD-independent lactate dehydrogenase: select Pseudomonas stutzeri (Pseudomonasstutzeri) SDM CCTCC No.M206010 strain to inoculate in 1.5% agarose containing 0.5% DL- Sodium lactate solid slant minimal medium, cultured at 30°C for 20 hours. Put the above-mentioned cultured strains into 50 ml of liquid basic medium containing 0.5% DL-sodium lactate with an inoculation loop and inoculate 1 to 2 loops under aseptic conditions, and culture it on a shaker at 180 rpm for 10 hours at 30°C. , to produce seeds;

[0059] With a 5% (volume ratio) inoculum size, the inoculum was placed in 150 ml of liquid basic medium containing 1% DL-sodium lactate, and cultured on a shaker at 30°C until the enzyme activity of NAD-independent lactate dehydrogenase reached When the concentration is 200 units / liter, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com