Method for extracting black carbon absorption material using plant ash as raw material

An adsorption material, a technology of plant ash, which is applied in the field of extracting and preparing black carbon adsorption materials with plant ash as raw materials, achieving the effect of high specific surface area, high carbon content and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

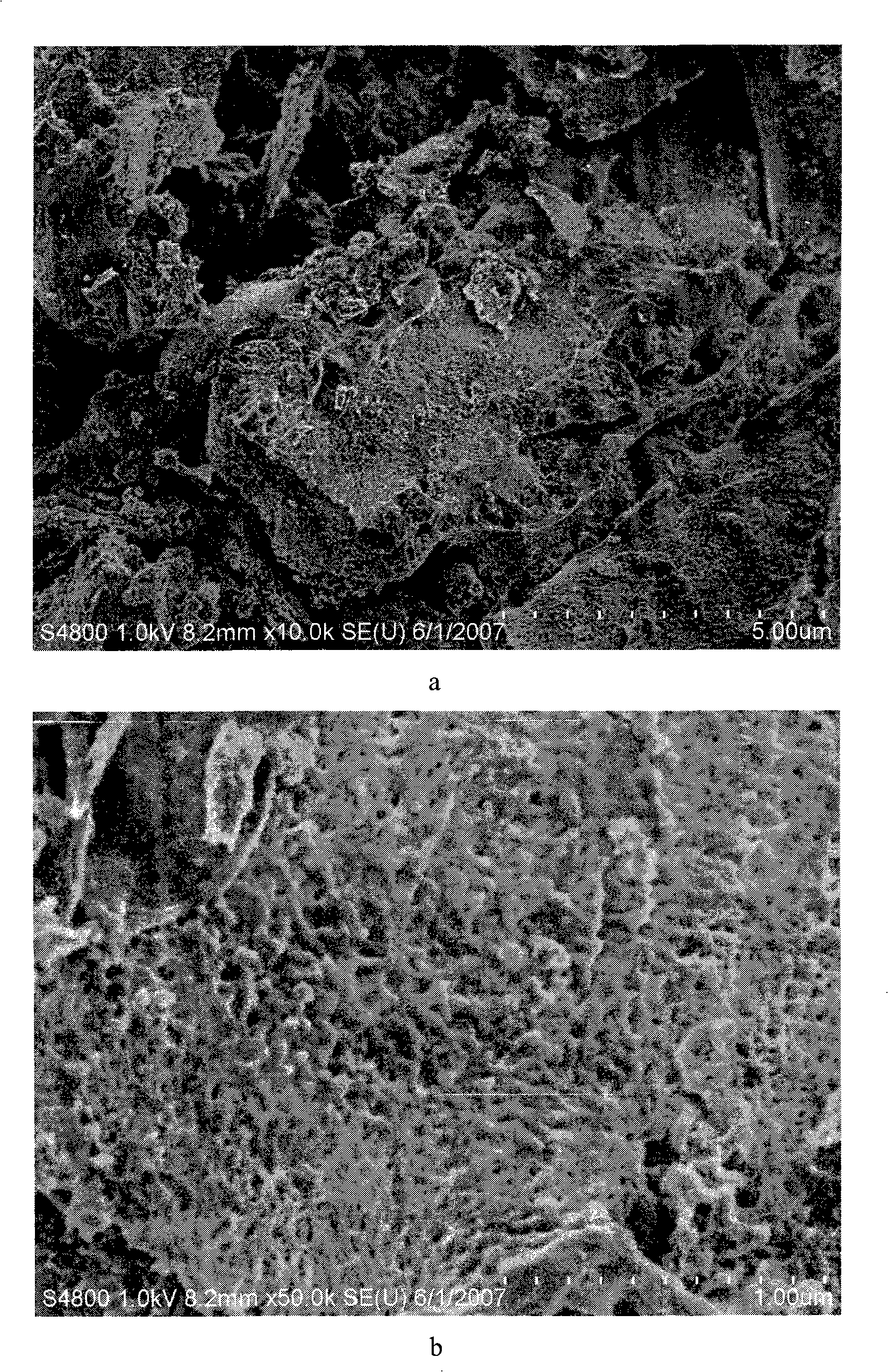

Image

Examples

Embodiment 1

[0024] Commercial concentrated hydrochloric acid is diluted with deionized water to obtain solution A (hydrofluoric acid concentration is 2mol / L); commercial hydrofluoric acid is diluted with deionized water to obtain solution B (hydrofluoric acid concentration is 2mol / L); solution A Mix with solution B in a ratio of 1:1 to obtain solution C (the concentration of hydrochloric acid and hydrofluoric acid in the mixed solution is 1mol / L);

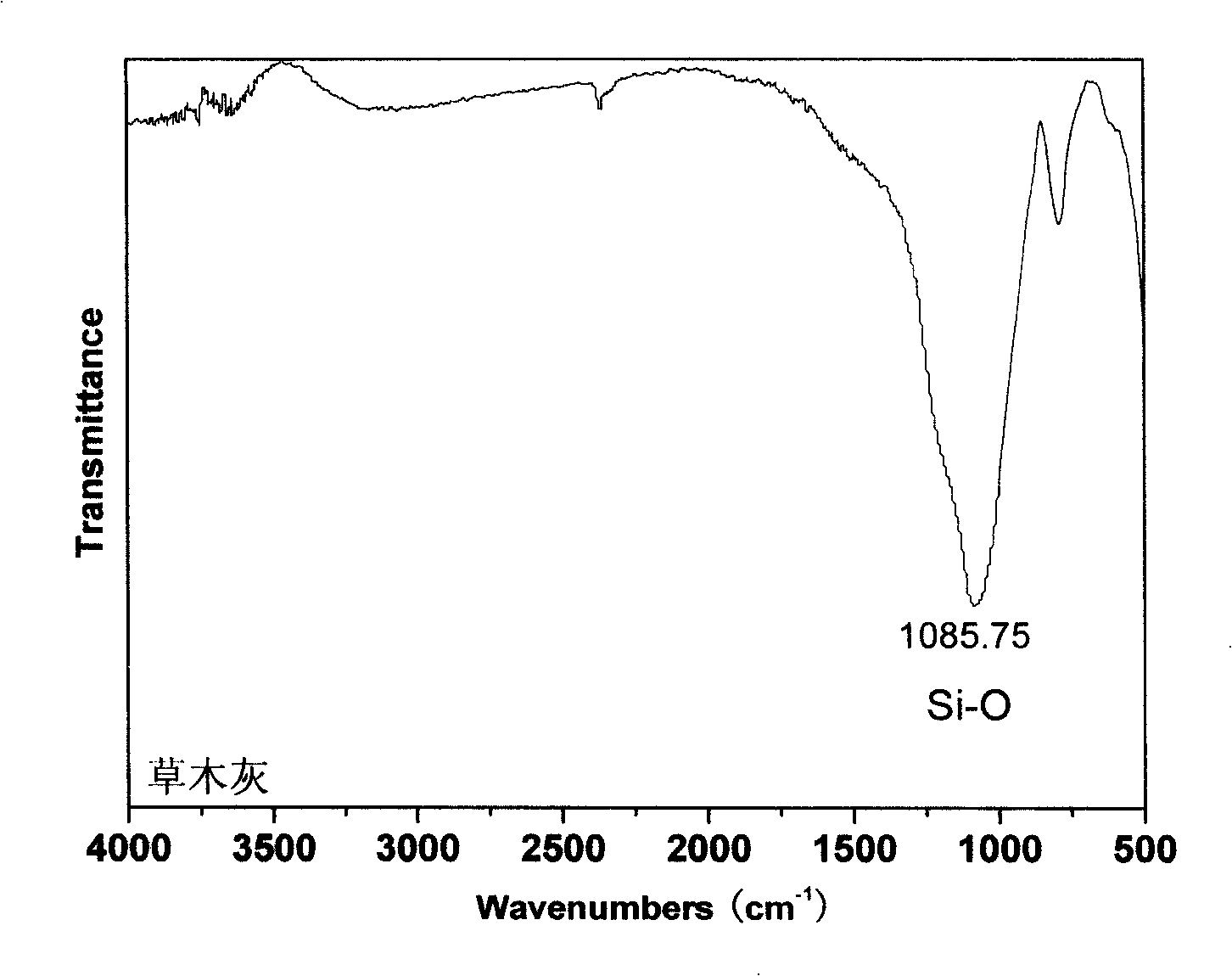

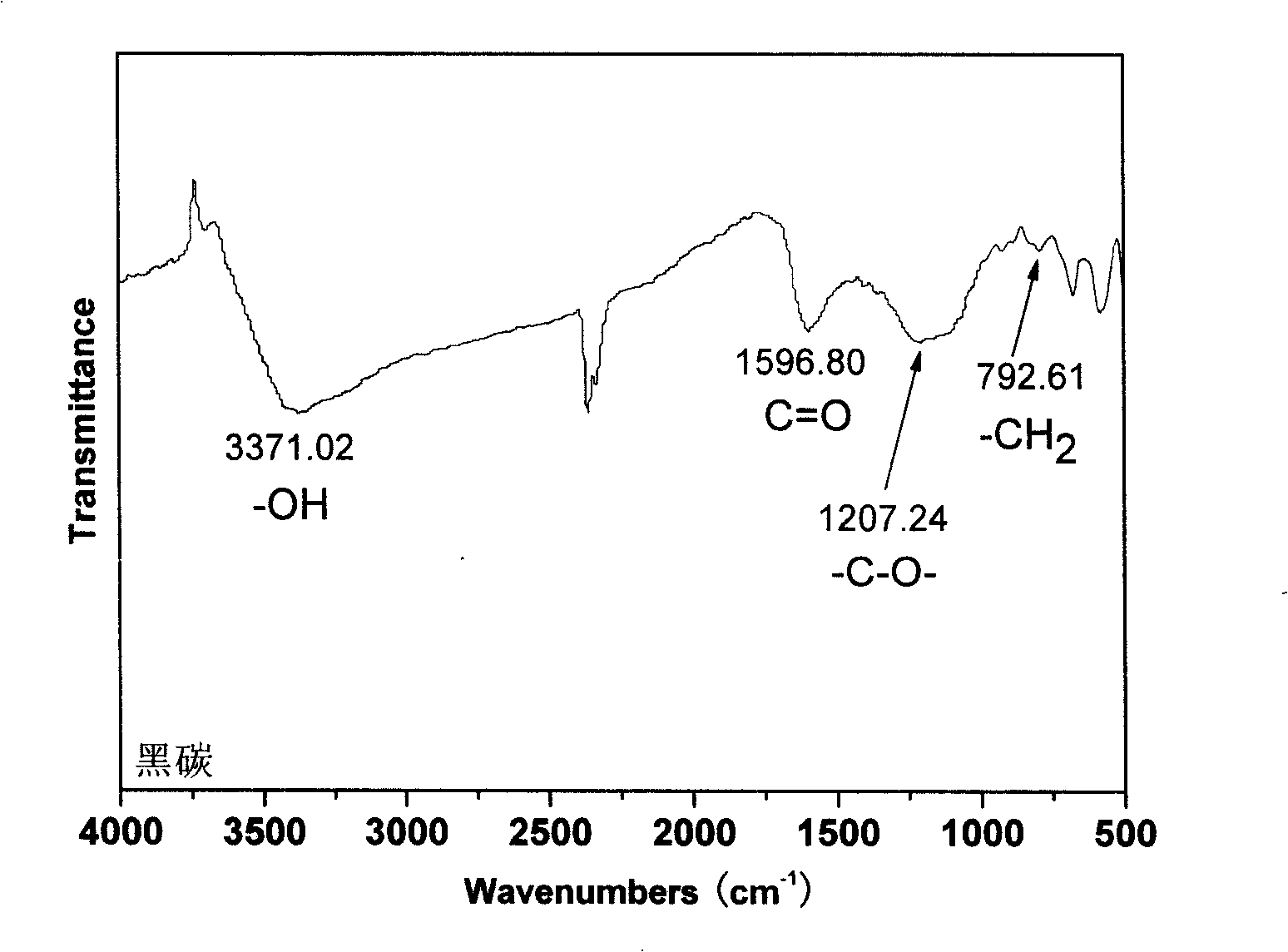

[0025] Add 2Kg rice straw plant ash in 10L plastic barrel (infrared spectrogram sees figure 2 ), add solution A under slow mechanical stirring, adjust the solid-liquid volume ratio to 1:4, and mechanically stir for 4 hours at room temperature; Repeat this step for a batch of A solution for 4 times, and finally wash with deionized water 5 times to remove most of the metal ions such as iron, aluminum, calcium, etc. in plant ash;

[0026] Put the solid sample obtained in the previous step into another 10L plastic bucket, add solution C, adjust ...

Embodiment 2

[0030] Industrial waste hydrochloric acid is diluted with deionized water to obtain solution A (hydrofluoric acid concentration is 1mol / L); commercial hydrofluoric acid is diluted with deionized water to obtain solution B (hydrofluoric acid concentration is 1mol / L); solution A Mix with solution B in a ratio of 1:1 to obtain solution C (the concentration of hydrochloric acid and hydrofluoric acid in the mixed solution is 0.5mol / L);

[0031] Add 1.5Kg wheat straw ash into a 10L plastic bucket, add solution A under slow mechanical stirring, adjust the solid-liquid volume ratio to 1:3, and mechanically stir for 6 hours at room temperature; Subsequent steps are dealt with together. The resulting solid is repeated with the next batch of A solution and this step is processed 4 times, and finally washed 4 times with deionized water to remove most of the metal ions such as iron, aluminum, calcium, etc. in the plant ash;

[0032] Put the solid sample obtained in the previous step into ...

Embodiment 3

[0036] Dilute industrial waste hydrochloric acid with deionized water to obtain solution A (hydrofluoric acid concentration is 0.5mol / L); dilute industrial waste hydrofluoric acid with deionized water to obtain solution B (hydrofluoric acid concentration is 0.5mol / L); Mix solution A and solution B in a ratio of 1:1 to obtain solution C (the concentration of hydrochloric acid and hydrofluoric acid in the mixed solution is 0.25mol / L);

[0037] Add 2Kg corn stalk plant ash into a 10L plastic bucket, add solution A under slow mechanical stirring, adjust the solid-liquid volume ratio to 1:5, and mechanically stir for 5 hours at room temperature; after standing still, the solid-liquid separation is separated by suction filtration, and the obtained liquid is collected for subsequent follow-up steps together. The resulting solid is repeated with the next batch of A solution and this step is reprocessed 4 times, and finally washed 5 times with deionized water to remove most of the meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com