Process for preparing ambroxol, analogue thereof or salts thereof

A synthesis method and amino technology are applied in the synthesis field for preparing ambroxol hydrochloride, and can solve the problems of reduced yield, complicated operation and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

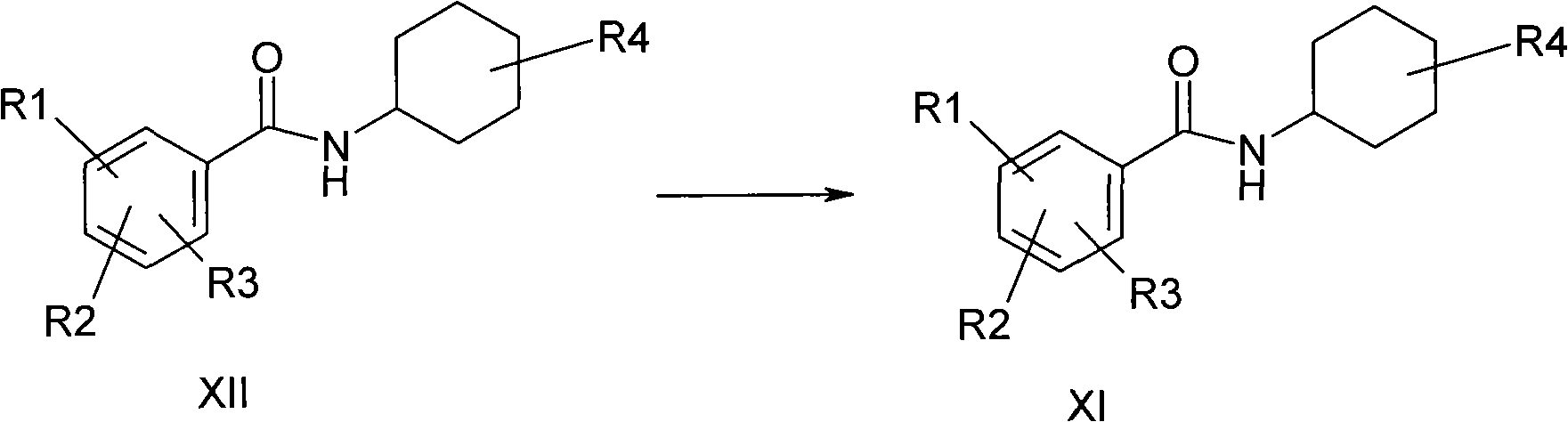

Method used

Image

Examples

preparation example 1

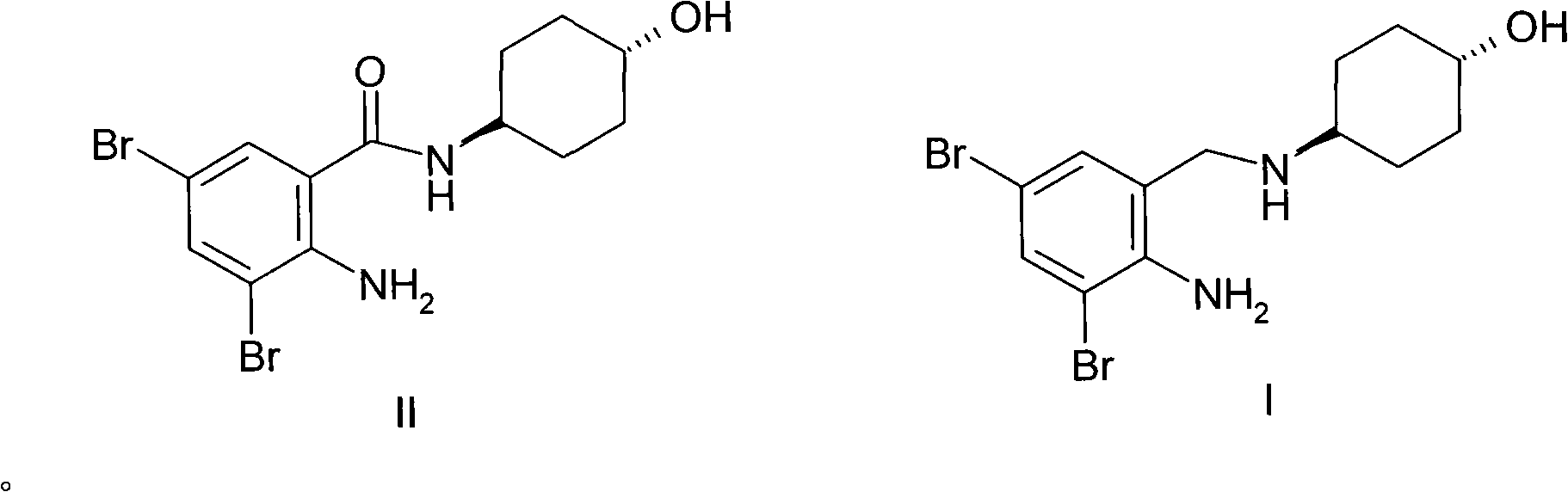

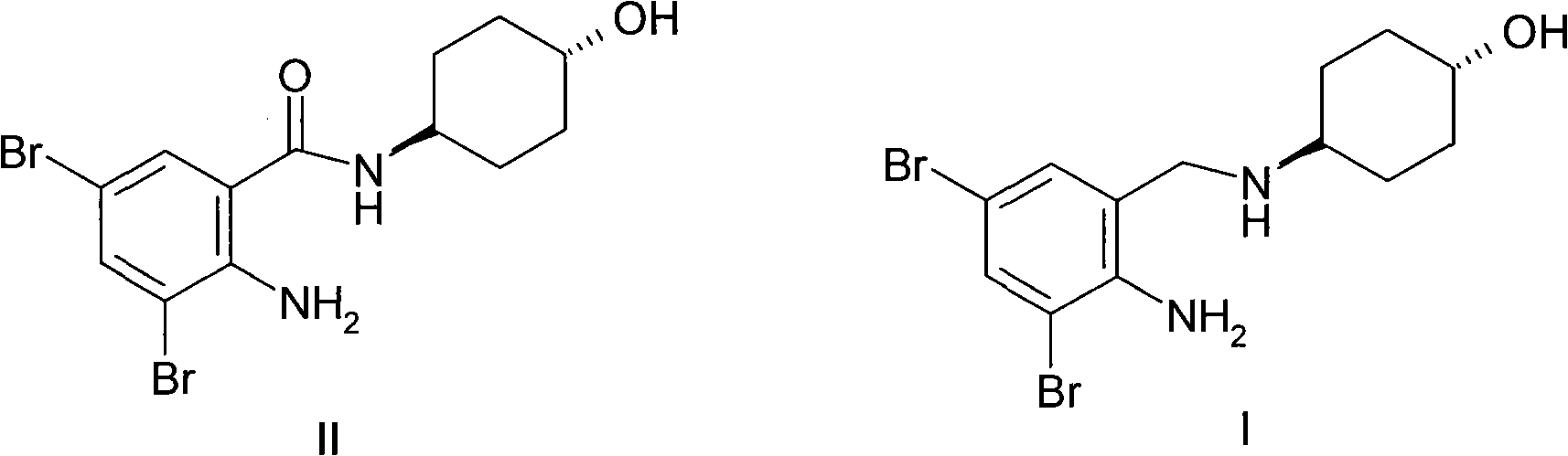

[0019] Preparation Example 1 N-(trans-4-hydroxycyclohexyl)-2-amino-3,5-dibromobenzamide (II)

[0020]

[0021] According to the method reported in the literature (ES 8605219), N-(trans-4-hydroxycyclohexyl)-2-amino-3,5 -dibromobenzamide (II), its three-step total yield is 61%.

Embodiment 1

[0022] Example 1 N-(trans-4-hydroxycyclohexyl)-N-(2-amino-3,5-dibromobenzyl)amine (I) (LiCl method)

[0023]

[0024] Dissolve N-(trans-4-hydroxycyclohexyl)-2-amino-3,5-dibromobenzamide (II, 3.90g, 0.010mol) in 120ml of dry tetrahydrofuran, and cool to 0 ℃, add 0.46g (0.011mol) of anhydrous lithium chloride to form a suspension, add 0.25g (0.007mol) of sodium borohydride, keep 0℃ for 4 hours, rise to room temperature, evaporate the solvent under reduced pressure, and use the residue Extract with 80ml of ethanol, acidify the extraction solution with concentrated hydrochloric acid, add a small amount of ether, and crystallize the crude product of ambroxol hydrochloride. The crude product was recrystallized from ethanol-ether to obtain 3.65 g of pure ambroxol hydrochloride (88% yield). Mp: 216-217.5. ESI MS: 379 (M+1).

Embodiment 2

[0025] Example 2 N-(trans-4-hydroxycyclohexyl)-N-(2-amino-3,5-dibromobenzyl)amine (I)(TiCl 4 Law)

[0026] Dissolve N-(trans-4-hydroxycyclohexyl)-2-amino-3,5-dibromobenzamide (II, 3.97g, 0.012mol) in 120ml of dry tetrahydrofuran, and cool to 0 ℃, add 1.40ml (0.013mol) of titanium tetrachloride, add 0.30g (0.008mol) of sodium borohydride, keep the reaction at 0℃ for 4 hours, rise to room temperature, evaporate the solvent under reduced pressure, and extract 80ml of the residue with ethanol to extract The solution was acidified with concentrated hydrochloric acid, and a small amount of ether was added to crystallize crude ambroxol hydrochloride. The crude product was recrystallized from ethanol-ether to obtain 4.75 g of pure ambroxol hydrochloride (95% yield). MP: 216-217. ESI MS: 379 (M+1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com