Azo compound or salts thereof

An azo compound, sulfamoyl technology, applied in disazo dyes, organic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

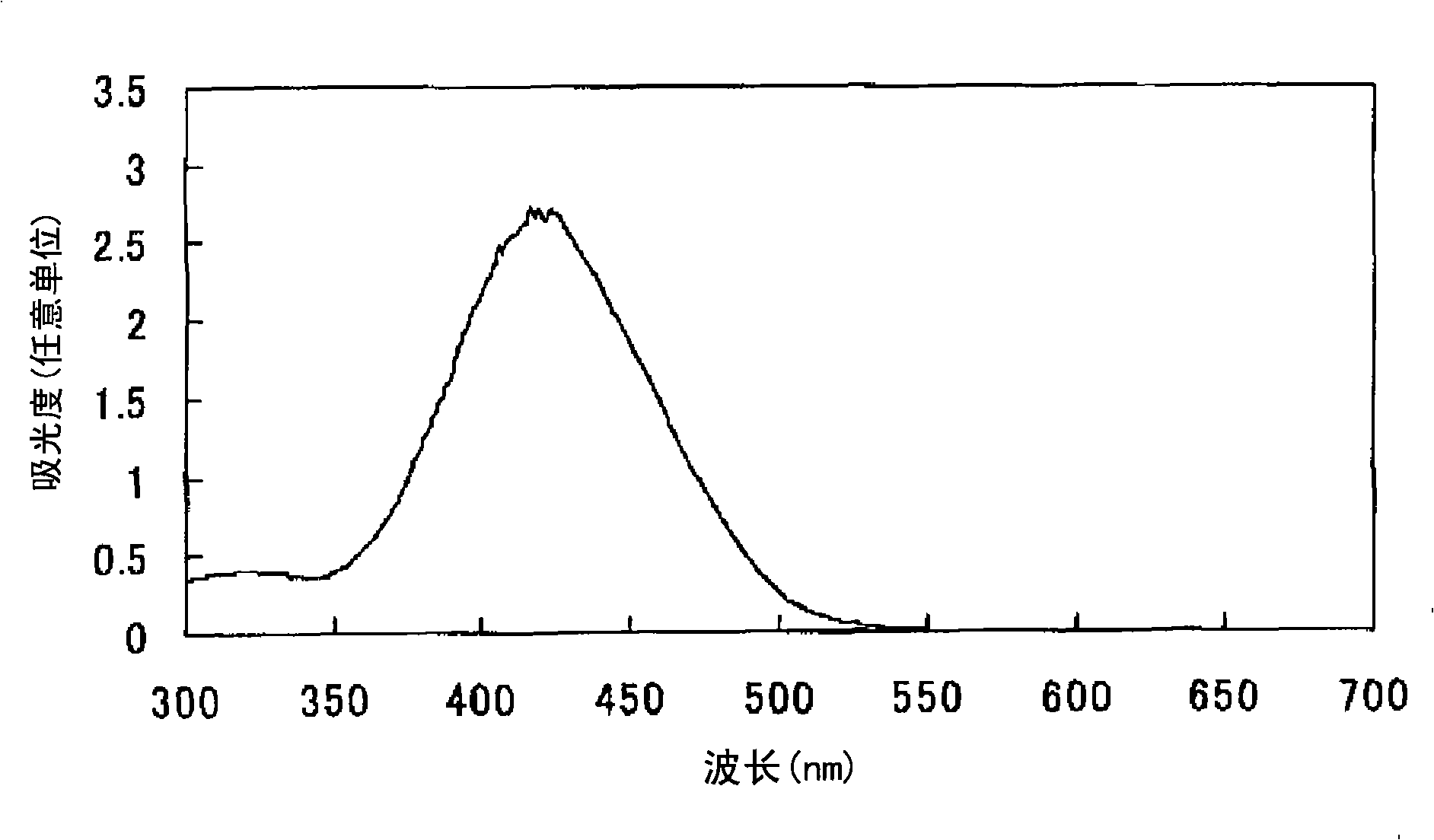

[0070] After adding 120 parts of water and 120 parts of N-methylpyrrolidone to 20 parts of 4'-aminoazobenzene-4-sulfonic acid represented by formula (a-1), adjust the pH with 30% aqueous sodium hydroxide solution under ice-cooling 7 to 8. The following operations were carried out under ice cooling. Add 9.2 parts of sodium nitrite and stir for 30 minutes. 48.7 parts of 35% hydrochloric acid was added a little at a time to form a brown solution and stirred for 2 hours. Dissolve 6.3 parts of sulfamic acid in 40 parts of water to form an aqueous solution, add the aqueous solution into the reaction solution, and stir to obtain a suspension containing diazonium salt.

[0071]

[0072] After adding 300 parts of water to 12.5 parts of N,N'-dimethylbarbituric acid represented by the formula (c-1), the pH was adjusted to 8-9 with a 30% aqueous sodium hydroxide solution.

[0073]

[0074] Under ice-cooling, stir the above-mentioned barbituric acid-base aqueous solution to form a...

Embodiment 2

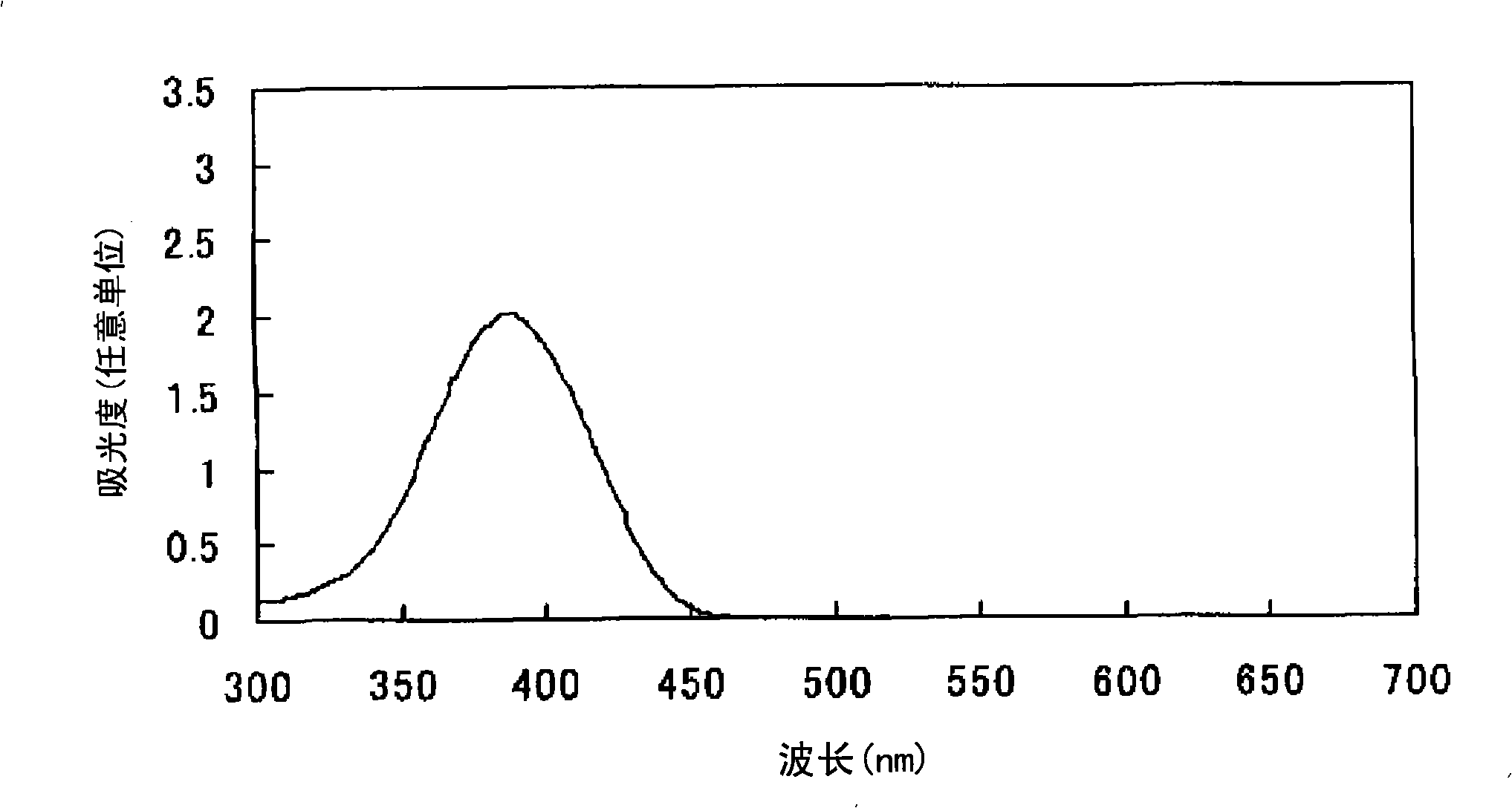

[0088] Put 5 parts of azo compound (I-1), 50 parts of chloroform, and 2.1 parts of N,N-dimethylformamide into a flask equipped with a condenser tube and a stirring device, and keep the temperature below 20°C while stirring Add 6 parts of thionyl chloride dropwise. After completion of the dropwise addition, the temperature was raised to 50°C, the same temperature was maintained for 5 hours to allow the reaction to proceed, and then cooled to 20°C. A mixed solution of 4 parts of 1,1,3,3-tetramethylbutylamine and 14 parts of triethylamine was added dropwise while maintaining the temperature of the cooled reaction solution at 20° C. or lower while stirring. Then, stirring was carried out at the same temperature for 5 hours to allow the reaction to proceed. Next, the solvent in the obtained reaction mixture was evaporated with a rotary evaporator, and then a small amount of methanol was added, followed by vigorous stirring. This mixture was added to a liquid mixture of 29 parts o...

Embodiment 3

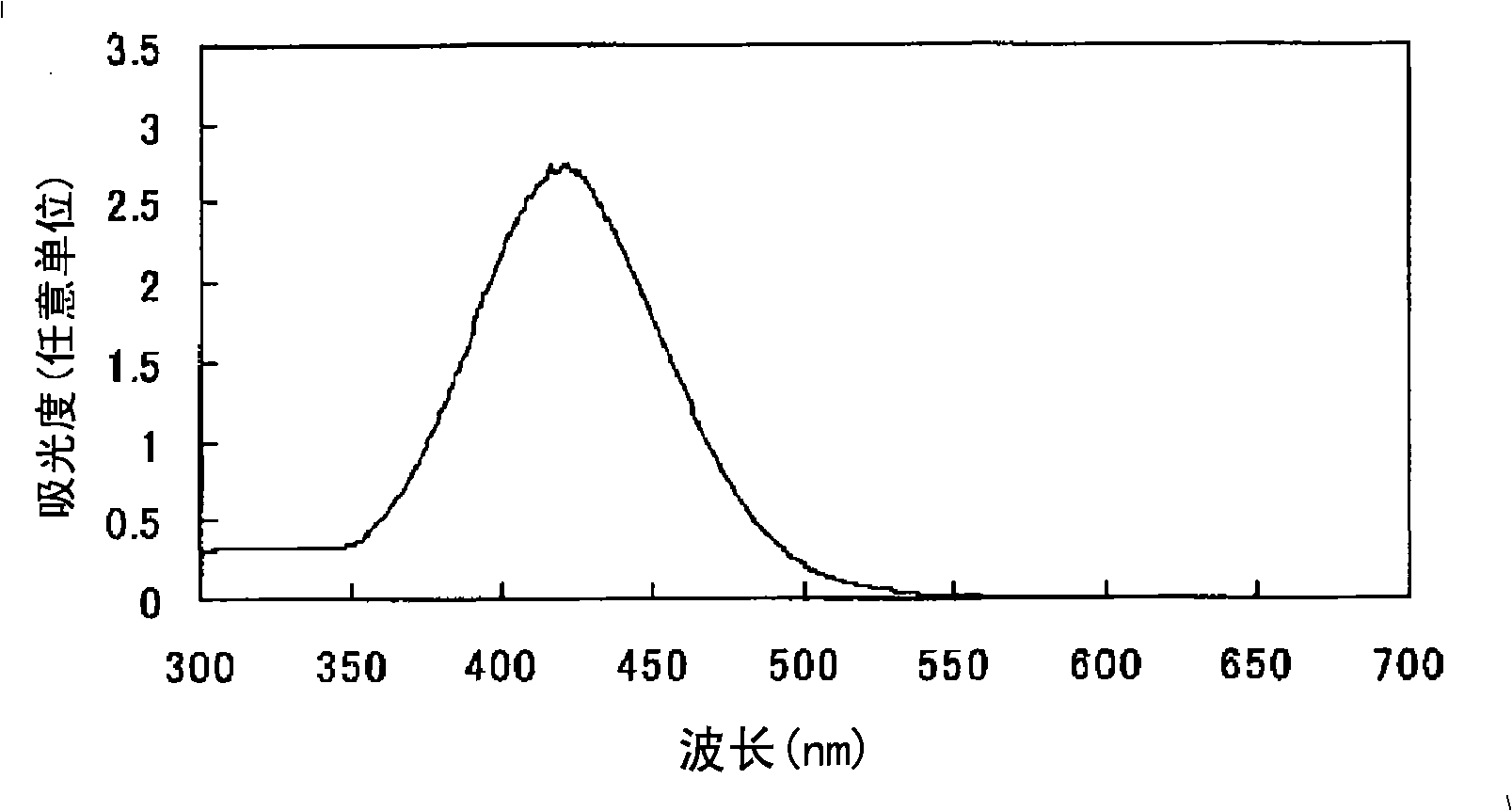

[0097] After adding 72 parts of water and 72 parts of N-methylpyrrolidone to 12 parts of 4'-aminoazobenzene-4-sulfonic acid represented by formula (a-1), adjust the pH to 7 with 30% aqueous sodium hydroxide solution ~8. The following operations were carried out under ice cooling. Add 5.5 parts of sodium nitrite and stir for 30 minutes. 29.2 parts of 35% hydrochloric acid were added a little at a time to form a brown solution and stirred for 2 hours. Dissolve 3.8 parts of sulfamic acid in 37.7 parts of water to form an aqueous solution, add the aqueous solution to the reaction solution, and stir to obtain a suspension containing diazonium salt.

[0098] After adding 68.9 parts of water to 6.9 parts of N,N'-diisopropylbarbituric acid represented by the formula (c-2), the pH was adjusted to 8-9 with a 30% aqueous sodium hydroxide solution.

[0099]

[0100] Under ice-cooling, stir the above-mentioned alkali aqueous solution of barbituric acid to form a colorless solution, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com