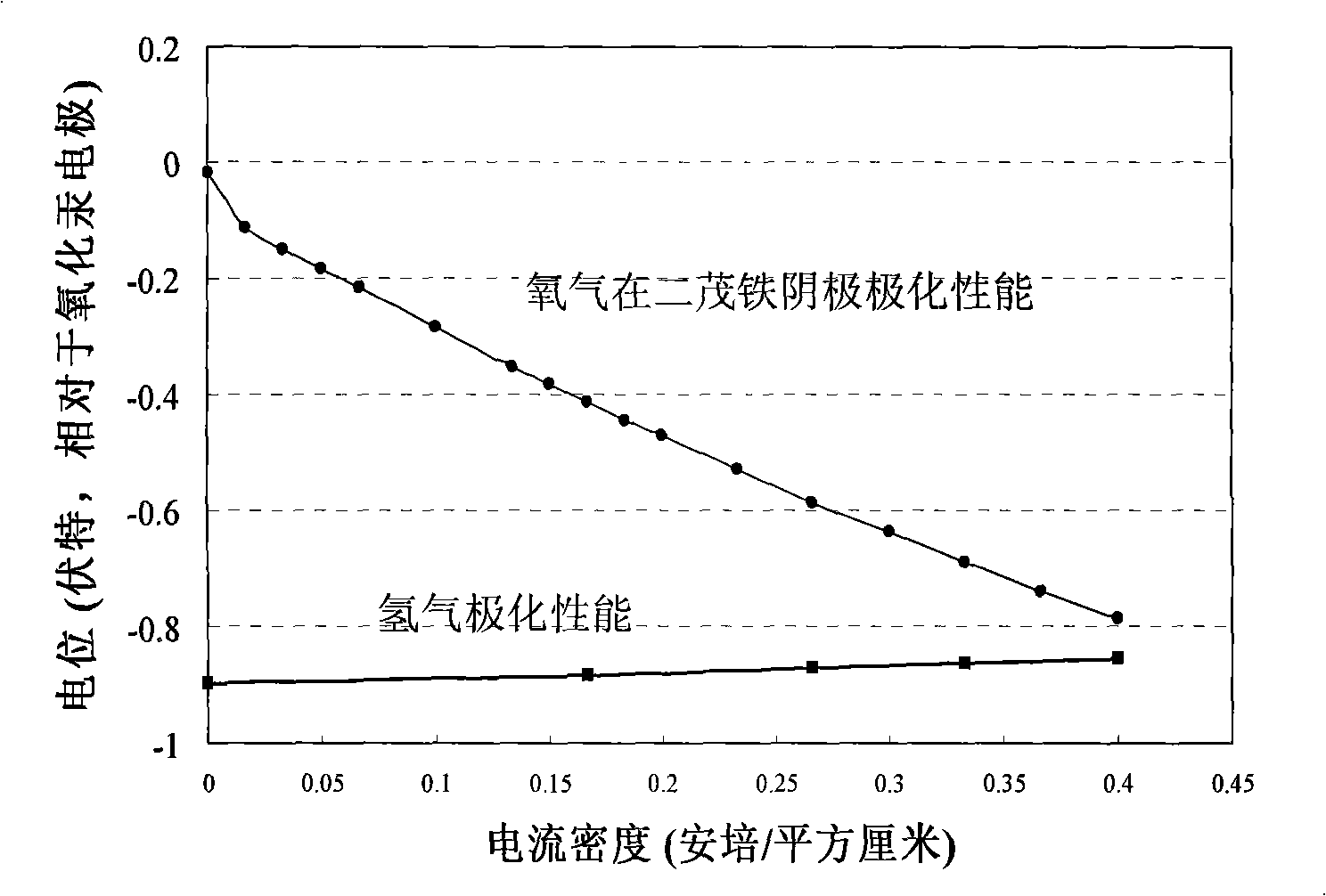

Hydrogen fuel cell using ferrocene as cathode catalyst

A cathode catalyst, fuel cell technology, applied in fuel cells, solid electrolyte fuel cells, battery electrodes, etc., can solve the problems of poor catalyst performance and less research, and achieve the effect of reducing costs, facilitating popularization, and solving the lack of platinum resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]The ferrocene is dissolved in the solvent by using petroleum ether as a solvent, and the mass ratio of the solvent to the ferrocene is 1:5 to obtain a ferrocene solution.

[0034] The carbon black that has been treated with water repellency, with polytetrafluoroethylene emulsion (5wt%) as a binder, is prepared into a slurry at a mass ratio of 1:5, coated on the carbon cloth that has been treated with water repellency, and dried in the air. After calcining in a muffle furnace at 350° C. for one hour, it was naturally cooled to room temperature to obtain a cathode substrate. Then dip into the above-mentioned ferrocene solution and dry to form a hydrophobic ferrocene cathode.

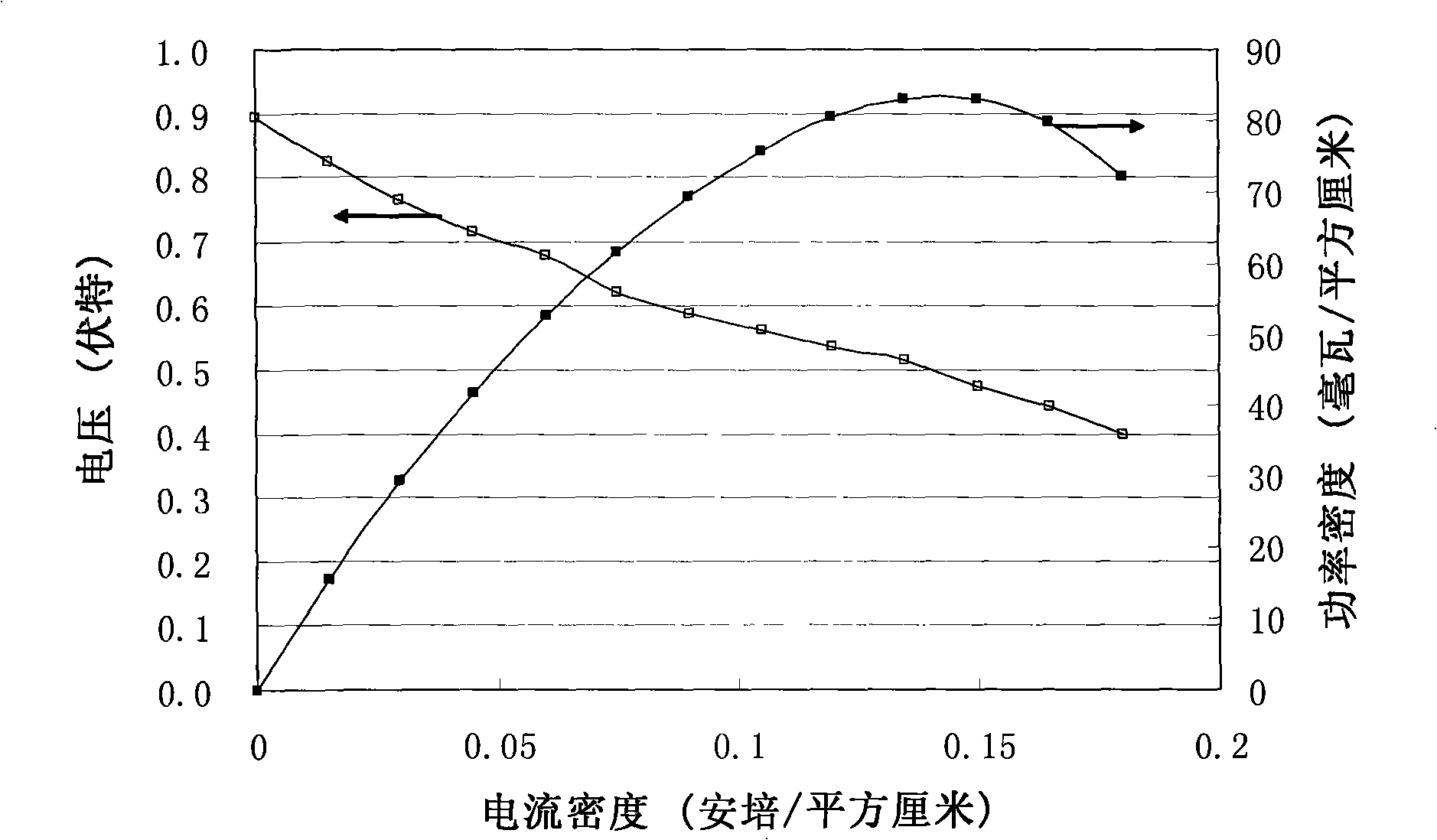

[0035] Use the negative electrode modulated in embodiment 1 to assemble into the alkaline fuel cell with ferrocene as negative catalyst, its performance is as follows figure 2 shown. The electrolyte is 6N KOH, and the operating temperature is 25 degrees Celsius.

Embodiment 2

[0037] The ferrocene is dissolved in the solvent with n-hexane as the solvent, and the mass ratio of the solvent to the ferrocene is 1:1.5 to prepare a ferrocene solution.

[0038] With the carbon black that has been treated with water repellency, take polytetrafluoroethylene emulsion (10wt%) as binder, adjust into slurry by mass ratio 1: 2.5, be coated on the carbon cloth that has been treated with water repellency, dry in the air After calcining in a muffle furnace at 350° C. for one hour, it was naturally cooled to room temperature to obtain a cathode substrate. Then dip into the above-mentioned ferrocene solution and dry to form a hydrophobic ferrocene cathode. Then dip into perfluorosulfonic acid-based resin solution (5wt%), and form a hydrophobic ferrocene cathode with proton conduction after drying.

[0039] Using the modulated cathode to assemble an alkaline fuel cell with ferrocene as the cathode catalyst, its performance is as follows figure 2 shown. The electrol...

Embodiment 3

[0041] The ferrocene is dissolved in the solvent by using tetrahydrofuran as a solvent, and the mass ratio of the solvent to the ferrocene is 1:0.1 to prepare a ferrocene solution.

[0042] With the carbon black that has been treated with water repellency, take polytetrafluoroethylene emulsion (10wt%) as binder, adjust into slurry by mass ratio 1: 0.1, be coated on the carbon cloth that has been treated with water repellency, dry in the air After calcining in a muffle furnace at 350° C. for one hour, it was naturally cooled to room temperature to obtain a cathode substrate. Then dip into the above-mentioned ferrocene solution and dry to form a hydrophobic ferrocene cathode. Then dip into perfluorosulfonic acid resin solution (5wt%), and form a hydrophobic ferrocene cathode with proton conduction after drying.

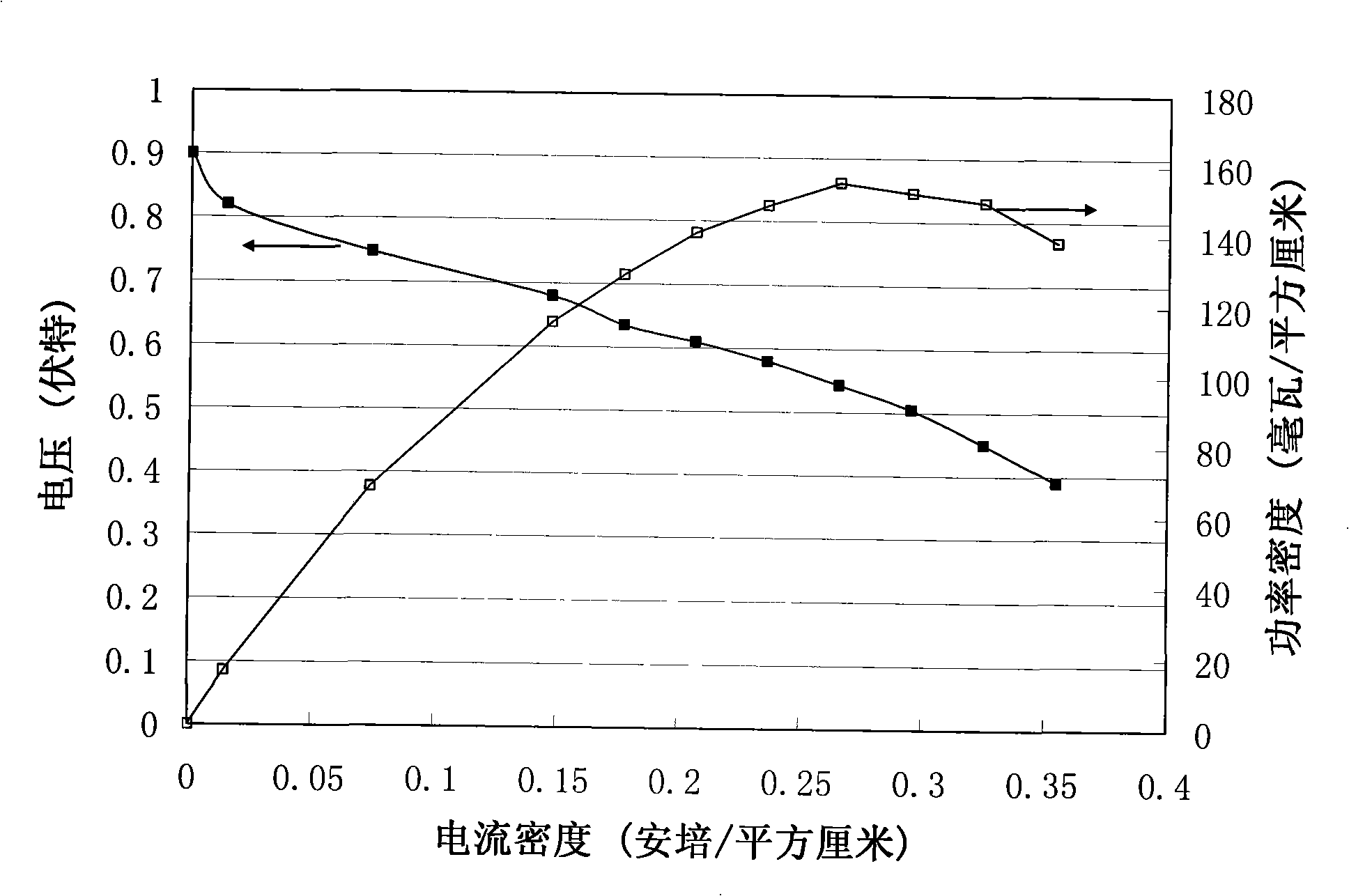

[0043] Use embodiment 2, the negative electrode modulated in 3 is assembled into the proton exchange membrane fuel cell with ferrocene as negative catalyst, its perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com