Method for measuring mercury content in loading paper for cigarette

A technology for cigarette tipping paper and measurement methods, which is applied in the direction of color/spectral characteristic measurement, etc., and can solve problems such as acid removal conditions, unsuitable measurement conditions, turbidity of the solution, and color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

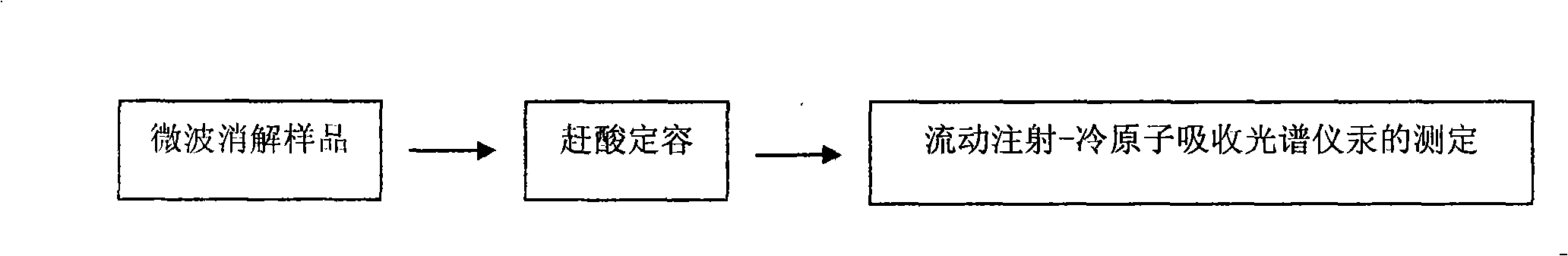

Method used

Image

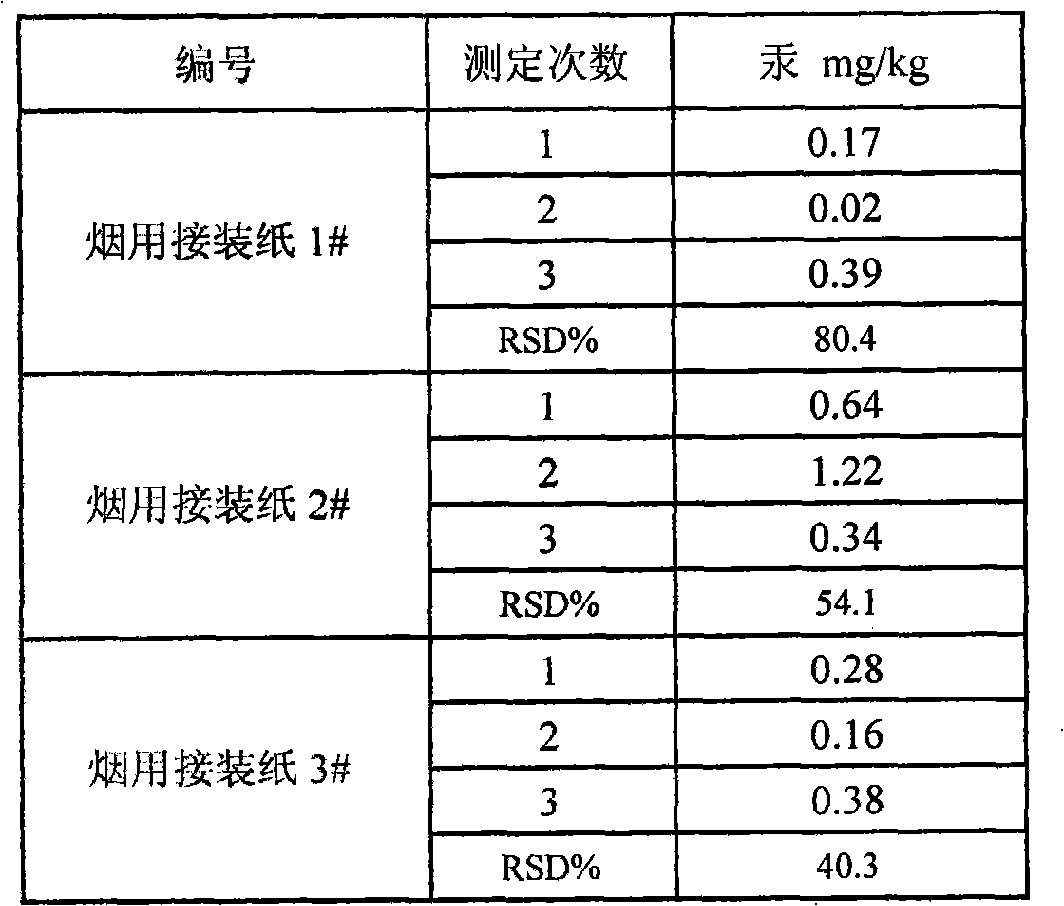

Examples

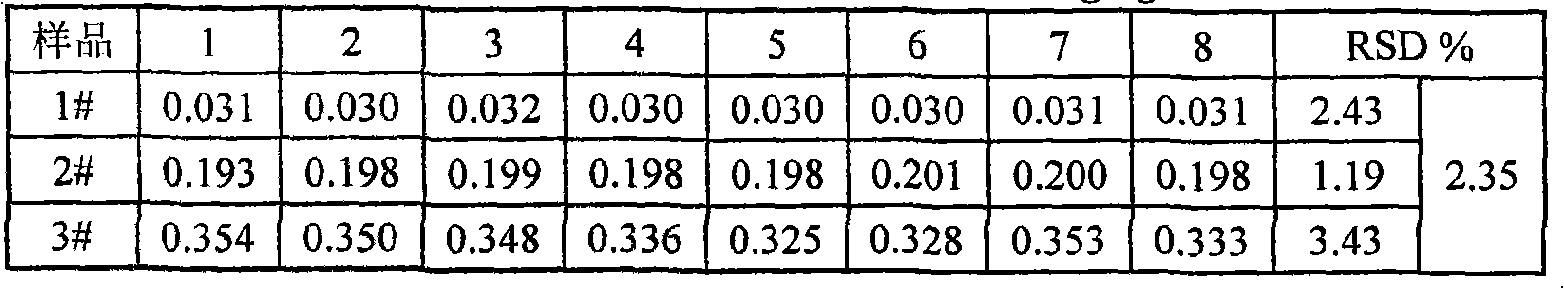

example 1

[0064] 1. Instruments and reagents: Mars type airtight microwave digestion instrument, equipped with TFM microwave digestion tank (CEM company of the United States). DKQ-4 intelligent temperature control electric heater (Shanghai Yiyao Analytical Instrument Co., Ltd.). Flow injection-cold atomic absorption spectrometer: FIMS400 flow injection mercury analyzer, AS 90 automatic sampler (Perkin Elmer, USA). Plastic volumetric flask: 50, 100mL. Electronic balance, CP225D type, with a sensitivity of 0.0001g (Sartorius AG company). Pipette: 50-100 μL. Pipette: 1, 10mL.

[0065] Ultra-pure water. The concentrated nitric acid of 65% by mass percentage, the hydrofluoric acid of 40% by mass percentage, the hydrochloric acid of 37% by mass percentage, the hydrogen peroxide (all excellent grade pure, German Merck KgaA company) of 30% by mass percentage. Cigarette tipping paper (cigarette manufacturers). Sodium borohydride, sodium hydroxide, and potassium permanganate were all analyt...

example 2

[0070] As described in Example 1, the tipping paper sample of brand B was selected, and the mercury in the sample was measured to be 0.608mg / kg.

example 3

[0072] As described in Example 1, a tipping paper sample of brand C was selected, and the mercury in the sample was measured to be 0.032 mg / kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com