Manufacturing method of metal-coated polyimide substrate

A technology of polyimide substrate and manufacturing method, which is applied in the direction of semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of increasing terminal pins and increasing the failure rate, and achieves the improvement of failure rate and industrial high value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] First, the polyimide sheet is made of Kapton 150EN (manufactured by Toray Dupont) using a magnetron sputtering device operating in a vacuum environment, and is carried out at 150°C in a chamber with a vacuum degree of 0.01 to 0.1Pa. minute heat treatment. Next, a nickel-chromium alloy layer with a thickness of 20 nm and a copper layer with a thickness of 300 nm were formed on the surface of the polyimide sheet using a nickel-chromium alloy target and a copper target containing 20% by mass of chromium relative to the total amount. The surface resistance of the obtained metal coating was 0.1Ω / □.

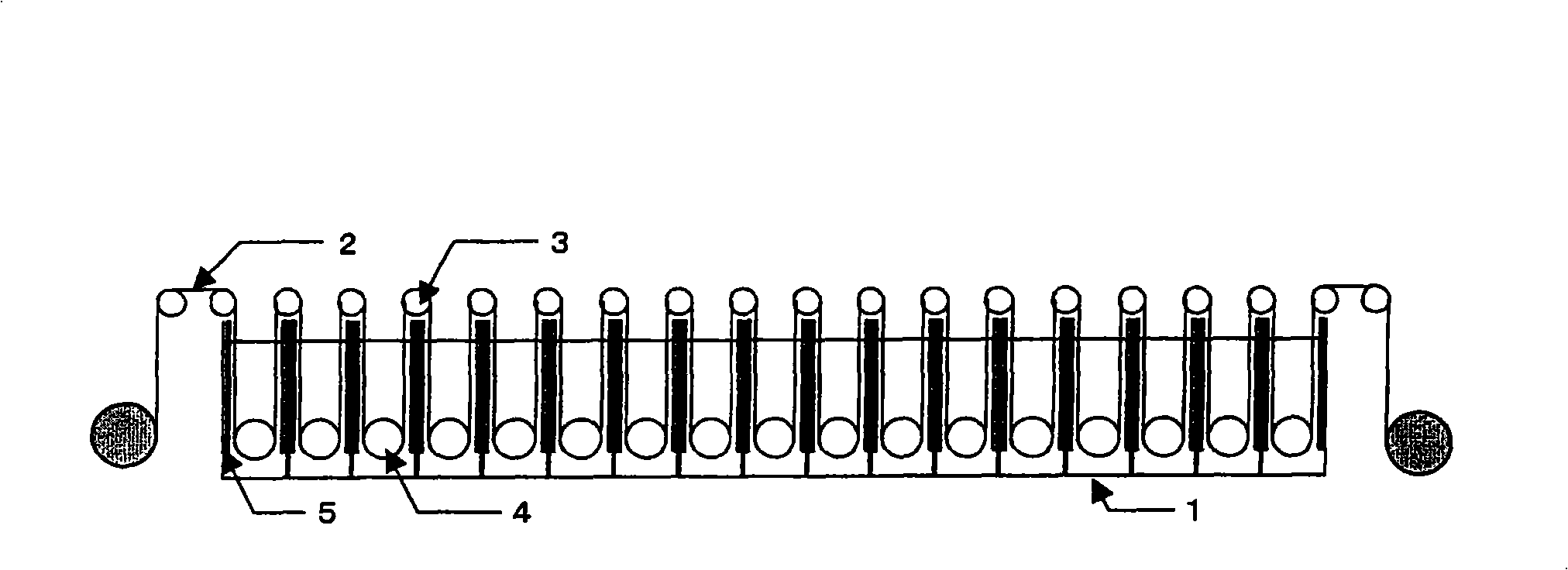

[0067] Then, using the obtained polyimide sheet after sputtering, using the above-mentioned continuous plating apparatus (number of plating tanks: 17 tanks), the copper plating layer was laminated on the copper film to obtain a metal-clad polyimide film with a copper conductor formed. Amine substrate. Here, as the anode of the above-mentioned continuous plating apparatus, a ...

Embodiment 2

[0070] Except that the ratio of the maximum value of the cathode current density in each electroplating tank to the minimum value is controlled to be 3, the same operation is performed as in Example 1, using the metal-clad polyimide substrate obtained, according to the above-mentioned "metal-clad polyimide "Evaluation method when the substrate is used as a COF", the occurrence rate of the positional deviation of the COF junction, the occurrence rate of the lead disconnection, and the occurrence rate of the tin plating film were calculated. The results are listed in Table 1.

Embodiment 3

[0072] The number of electroplating tanks of the above-mentioned continuous electroplating device is 12 tanks, and the total average current density is controlled to be 1.5A / dm 2 , and the ratio of the maximum value of the cathode current density in each electroplating tank to the minimum value is controlled to be 3, except that, the same operation as in Example 1, using the metal-clad polyimide substrate obtained, according to the above-mentioned "metal-clad "Evaluation method when polyimide substrate is used as COF" was used to obtain the defect rate of misalignment of the COF junction, the rate of lead disconnection, and the rate of tin plating peeling off. The results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com