Preparation of star-branched polyisobutene or isobutene-diene rubber

A technology of polyisobutylene and butyl rubber, which is applied in the field of polymer block copolymerization and can solve problems such as swelling phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

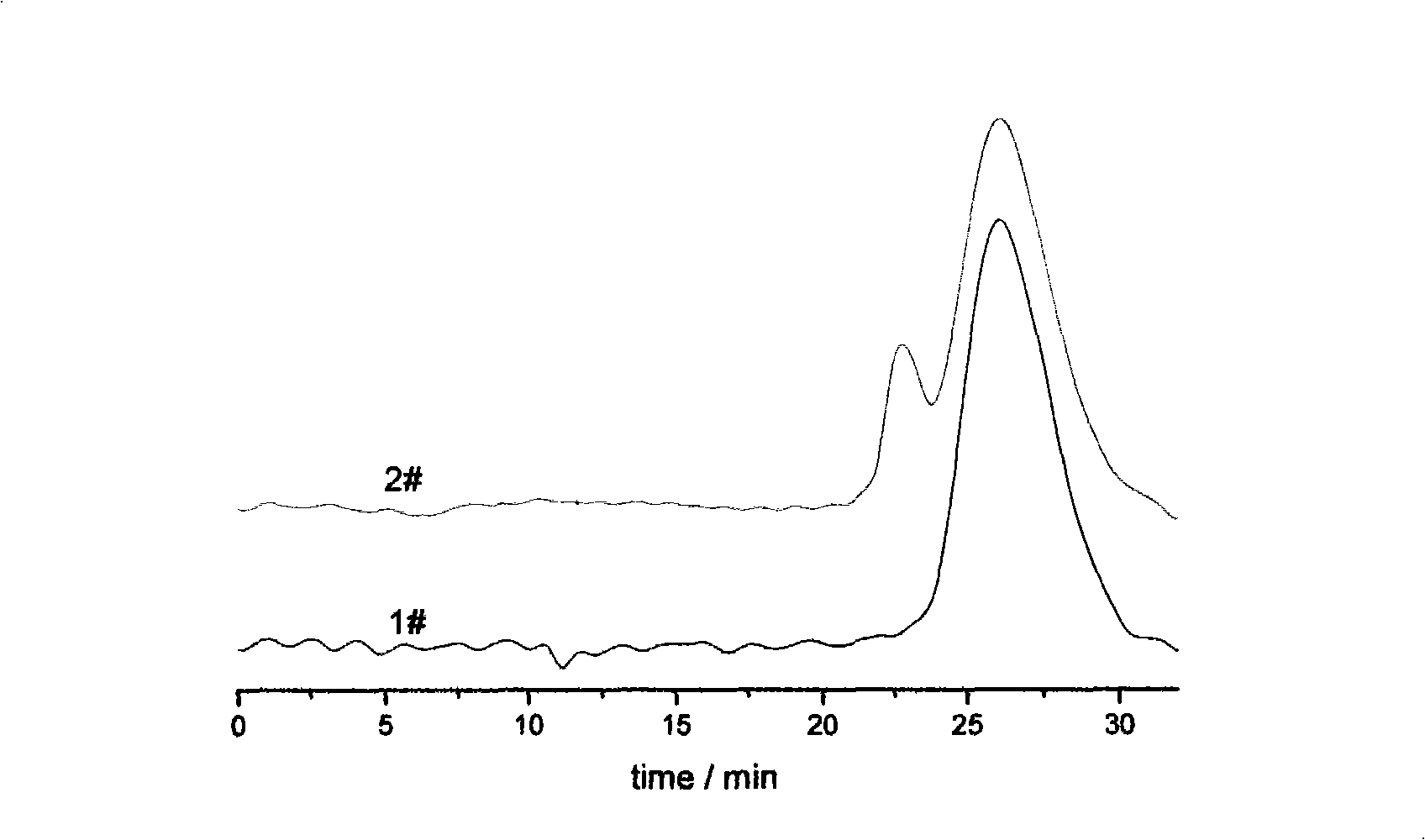

[0023] This experiment is a comparative experiment, comparing the star-branched butyl rubber prepared without adding the above-mentioned polystyrene-isoprene silicon-chloride block copolymer and adding polystyrene-isoprene silicon-chloride block copolymer .

[0024] Polymer bottle 1 # No added polystyrene-isoprene silyl chloride block copolymer, 2 # Add 0.0568 grams of polystyrene-isoprene silicon-chloride block copolymer (relative to 4% of the monomer mass,) in the bottle, and add 10 ml Methyl chloride was dissolved in 10ml cyclohexane. After the dissolution is complete, add 1ml 2-chloro-2,4,4-trimethylpentane TMPCl (0.002M), 0.5ml hexahydropyridine (0.004M) nucleophile and 1ml TiCl 4 (0.036M) co-initiator, aged for 5min, added a mixture of 2ml isobutene and 0.066ml isoprene, polymerized for 1h, precipitated with methanol, washed and dried. The products obtained are 1 # ,2 # . 2 # The molecular weight of the product increased significantly, the molecular weight distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com