Zein active peptide and preparation technique thereof

A corn protein and preparation technology, which is applied in the field of corn protein deep-processing products and corn protein active peptides, can solve the problems of difficult control of the reaction process of corn peptide production process, poor product quality, etc., and achieve stable production reaction process, low production cost, The effect of low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

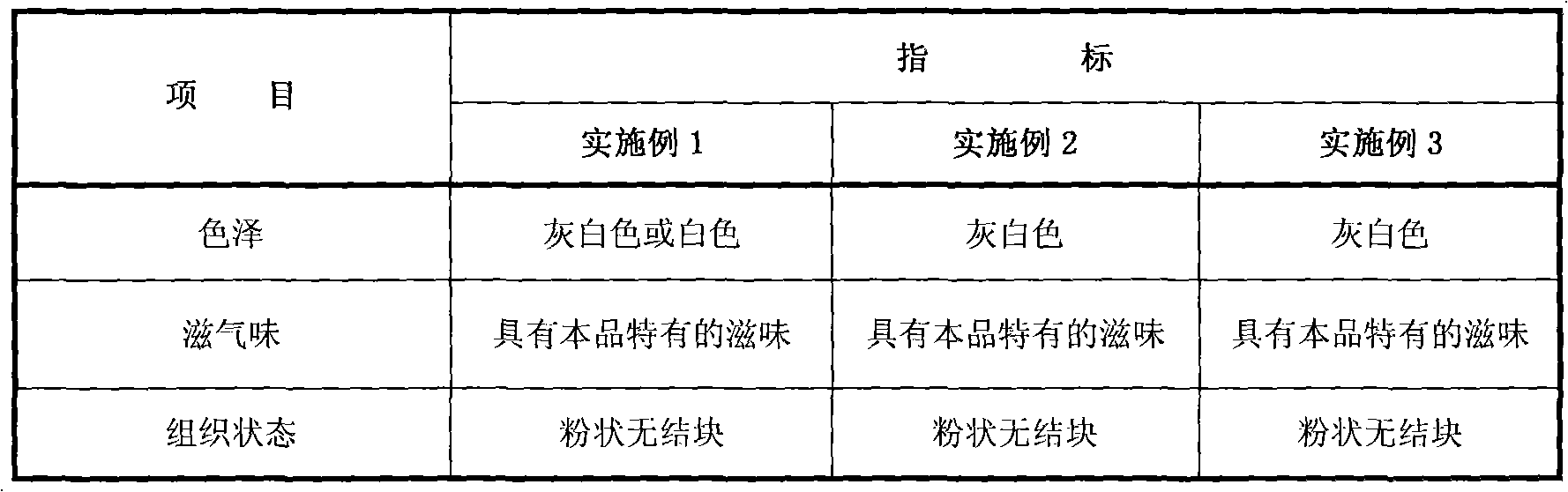

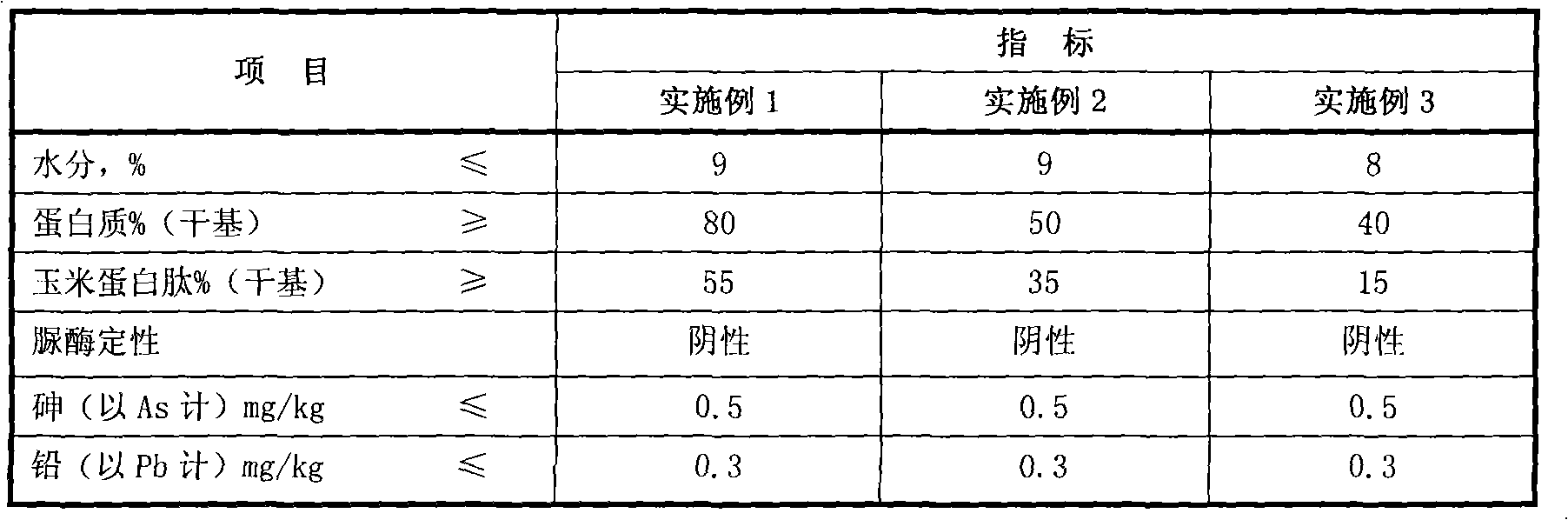

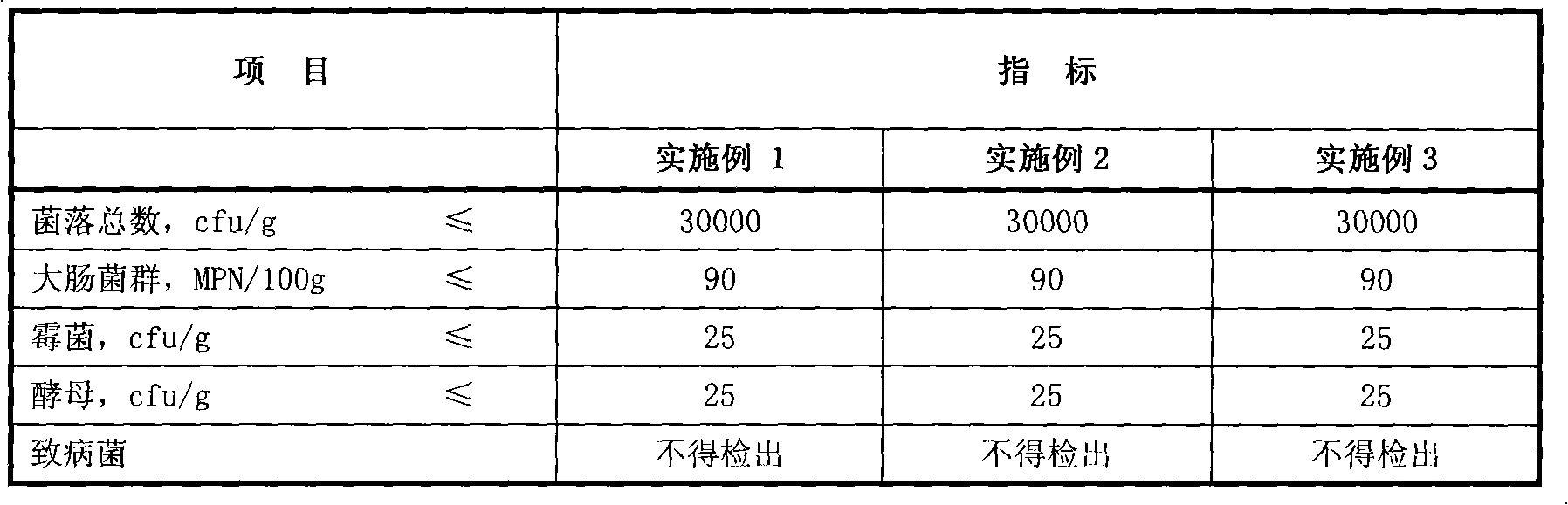

Examples

Embodiment 1

[0022] 1. Crush zein into 80-100 mesh fine powder, add 8 times the weight of water to make a slurry, autoclave at 121°C for 10 minutes, and cool to 45±1°C.

[0023] 2. Add 0.1 times the weight of zein neutral protease to the slurry, and enzymatically hydrolyze for 1.5 hours at a temperature of 45±1°C.

[0024] 3. After autoclaving at 121°C for 10 minutes, cool to 45±1°C.

[0025] 4. Aseptically inoculate Aspergillus oryzae strains into the slurry by 10% of the total amount of the slurry, at a temperature of 35±1° C., put into a shaker for fermentation until 10 hours.

[0026] Analyze and test once per hour to measure x-ammonia nitrogen and peptide nitrogen. About 10% of x-ammonia nitrogen and 70-75% of the total nitrogen are the targets. After reaching the targets, sterilize at 121°C After 15 minutes, centrifuge (or filter), discard the precipitate, evaporate and concentrate the supernatant to 40BX, and then spray-dry (or freeze-dry) to make a finished product.

Embodiment 2

[0028] 1. Crush zein into 80-100 mesh fine powder, add 12 times the weight of water to make a slurry, autoclave at 121°C for 15 minutes, and cool to 45±1°C.

[0029] 2. Add 0.3 times the weight of zein neutral protease to the slurry, and enzymatically hydrolyze for 2 hours at a temperature of 45±1°C.

[0030] 3. After autoclaving at 121°C for 10 minutes, cool to 45±1°C.

[0031] 4. Aseptically inoculate Aspergillus oryzae strains into the slurry by 10% of the total amount of the slurry, at a temperature of 35±1° C., put into a shaker for fermentation until 11 hours.

[0032] Analyze and test once per hour to measure x-ammonia nitrogen and peptide nitrogen. About 10% of x-ammonia nitrogen and 70-75% of the total nitrogen are the targets. After reaching the targets, sterilize at 121°C After 15 minutes, centrifuge (or filter), discard the precipitate, evaporate and concentrate the supernatant to 40BX, and then spray-dry (or freeze-dry) to make a finished product.

Embodiment 3

[0034] 1. Crush zein into 80-100 mesh fine powder, add 15 times the weight of water to make a slurry, autoclave at 121°C for 20 minutes, and cool to 45±1°C.

[0035] 2. Add 0.5 times the weight of zein neutral protease to the slurry, and enzymatically hydrolyze for 3 hours at a temperature of 45±1°C.

[0036] 3. After autoclaving at 121°C for 10 minutes, cool to 45±1°C.

[0037] 4. Aseptically inoculate Aspergillus oryzae strains into the slurry by 10% of the total amount of the slurry, at a temperature of 35±1° C., put into a shaker for fermentation until 12 hours.

[0038] Analyze and test once per hour to measure x-ammonia nitrogen and peptide nitrogen. About 10% of x-ammonia nitrogen and 70-75% of the total nitrogen are the targets. After reaching the targets, sterilize at 121°C After 15 minutes, centrifuge (or filter), discard the precipitate, evaporate and concentrate the supernatant to 40BX, and then spray-dry (or freeze-dry) to make a finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com