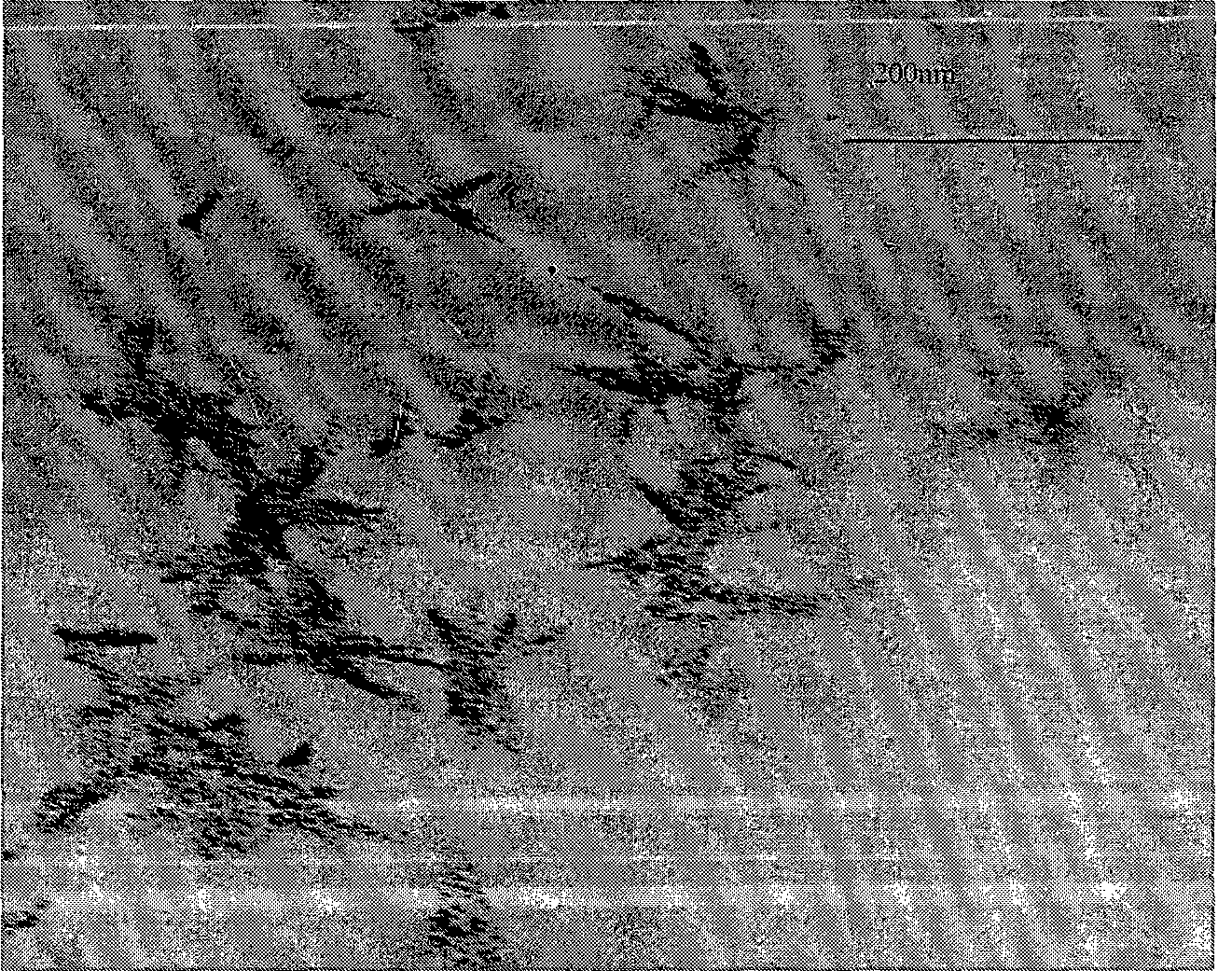

Method for preparing dendritic nano-silver by liquid phase synthesis

A liquid-phase synthesis, dendritic technology, applied in the field of material science, to achieve the effect of preventing shedding, environmentally friendly and non-toxic reagents, and increasing electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

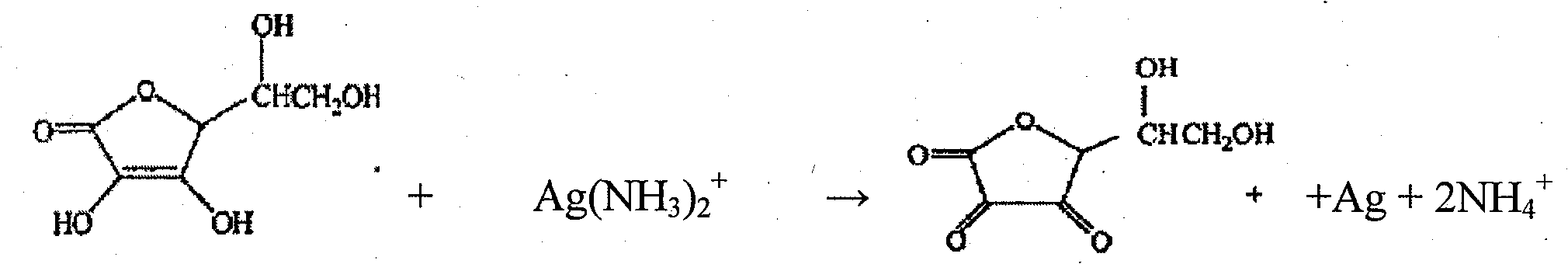

[0032] Silver nitrate is dissolved in deionized water to prepare a silver salt solution, then the silver salt solution and ammonia solution are mixed, and the mixing ratio is according to the silver ion (Ag) in the silver salt solution. + ) and NH in ammonia solution 3 ·H 2 The molar ratio of O to Ag + : NH 3 .H 2 O=1:2, prepared as Ag(NH 3 ) 2 Silver ammonia solution with OH concentration of 0.2mol / L.

[0033] In the silver ammonia solution of preparation, add tannic acid and polyvinylpyrrolidone (PVP), stir until mixing, prepare reaction solution, the addition of tannic acid is: the weight percent of tannic acid in silver ammonia solution is 0.1%; the addition amount of polyvinylpyrrolidone is: the weight percent of polyvinylpyrrolidone in the silver ammonia solution is 2%.

[0034] Add ascorbic acid to deionized water to prepare a concentration of 0.8mol / L ascorbic acid solution, drop it into the reaction solution at 20°C and a stirring speed of 200r / min for reductio...

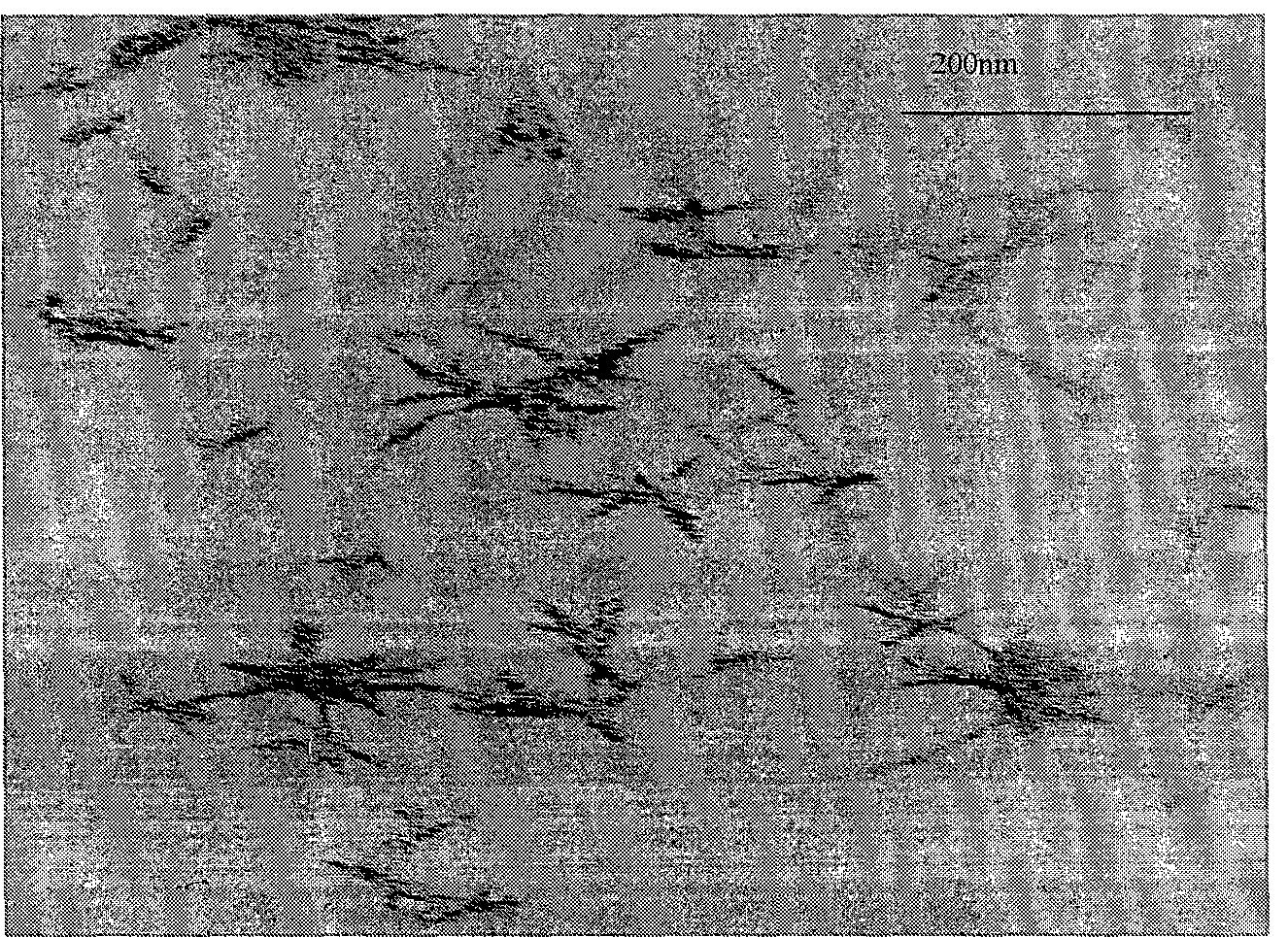

Embodiment 2

[0038] Silver nitrate is dissolved in deionized water to prepare a silver salt solution, then the silver salt solution and ammonia solution are mixed, and the mixing ratio is according to the silver ion (Ag) in the silver salt solution. + ) and NH in ammonia solution 3 ·H 2 The molar ratio of O to Ag + : NH 3 ·H 2 O=1:2, prepared as Ag(NH 3 ) 2 Silver ammonia solution with OH concentration of 0.2mol / L.

[0039] In the silver ammonia solution of preparation, add tannic acid and polyvinylpyrrolidone (PVP), stir until mixing, prepare reaction solution, the addition of tannic acid is: the weight percent of tannic acid in silver ammonia solution is 0.5%; the addition amount of polyvinylpyrrolidone is: the weight percent of polyvinylpyrrolidone in the silver ammonia solution is 0.5%.

[0040] Add ascorbic acid to deionized water to prepare a solution with a concentration of 0.7mol / L ascorbic acid, drop it into the reaction solution at 22°C and a stirring speed of 220r / min for...

Embodiment 3

[0044] Silver nitrate is dissolved in deionized water to prepare a silver salt solution, then the silver salt solution and ammonia solution are mixed, and the mixing ratio is according to the silver ion (Ag) in the silver salt solution. + ) and NH in ammonia solution 3 ·H 2 The molar ratio of O to Ag + : NH 3 ·H 2 O=1:2, prepared as Ag(NH 3 ) 2 Silver ammonia solution with an OH concentration of 0.1mol / L.

[0045]In the silver ammonia solution of preparation, add tannic acid and polyvinylpyrrolidone (PVP), stir until mixing, prepare reaction solution, the addition of tannic acid is: the weight percent of tannic acid in silver ammonia solution is 1%; the amount of polyvinylpyrrolidone added is: the weight percentage of polyvinylpyrrolidone in the silver ammonia solution is 0.1%.

[0046] Add ascorbic acid to deionized water to prepare a solution with a concentration of 0.6mol / L ascorbic acid, drop it into the reaction solution at 25°C and a stirring speed of 180r / min for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com