Method of homopolymerization of conjugated dienes or copolymerization of conjugated dienes and monovinyl aromatics

A conjugated diene and monomer technology, applied in the field of conjugated diene polymerization, can solve the problems of product structure and performance influence, coupling efficiency, reactive species, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

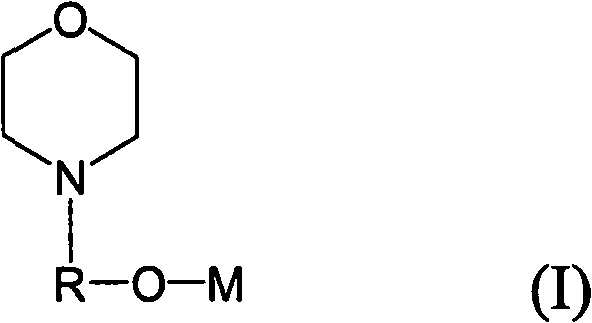

[0038] Under the protection of high-purity nitrogen, mixed solvent (mixture of cyclohexane and n-hexane: 82 / 18, mass ratio), 1,3-butadiene (Bd), and styrene (St) were added to the mixture according to the batching ratio. 5 liters of stainless steel polymerization reactor with stirring. The reactor was heated to 50° C. by heating the jacket with hot water, and n-butyllithium (Li) in the amount shown below and sodium morpholine ethoxide (Na) in the molar ratio to n-butyllithium in the molar ratio shown below were sequentially added. Polymerization was carried out at 50-120° C. for one hour, followed by the addition of tin tetrachloride (Sn) with n-butyllithium in the molar ratio shown below for coupling for 30 minutes. Then add isopropanol in an amount 1.2 times (molar ratio) of n-butyllithium to terminate the reaction, and condense with water vapor to obtain a random styrene-butadiene copolymer product. The microstructure of the product is shown in Table 1 below. The microstr...

Embodiment 2-4

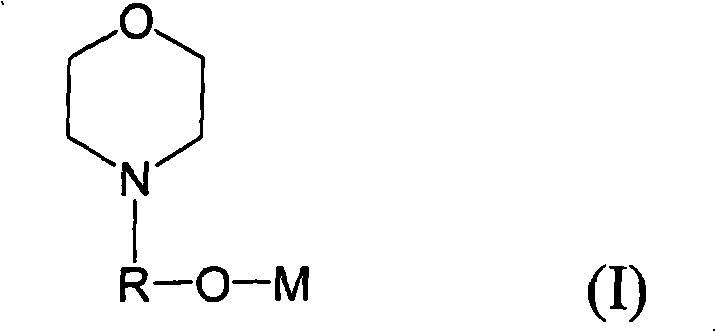

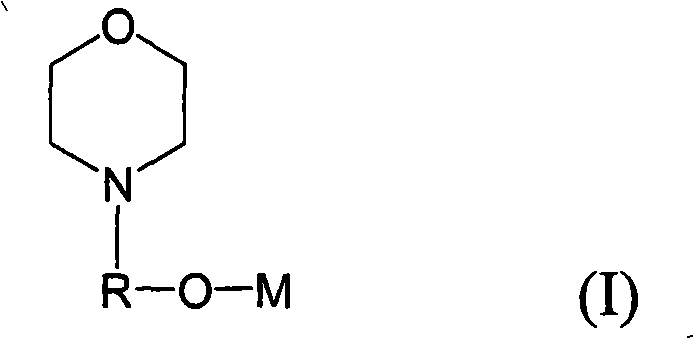

[0050] According to the procedure described in Example 1, the difference is that the structural regulators added to the polymerization system become sodium morpholine propoxide, sodium morpholine butoxide and sodium morpholine pentoxide respectively, that is, R in the formula I is respectively -CH 2 CH 2 CH 2 -, -CH 2 CH 2 CH 2 CH 2 -and-CH 2 CH 2 CH 2 CH 2 CH 2 -. The results are shown in Table 2.

[0051] Table 2

[0052] serial number

Embodiment 5-7

[0054] Carry out according to the procedure described in Example 1, the difference is to adjust the dosage of the structure regulator added to the polymerization system, so that the ratio of it and organolithium becomes 1.0, 2.0 and 5.0 in turn. The results are shown in Table 3.

[0055] table 3

[0056] serial number

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com