Complex bacteria for preprocessing of restaurant garbage, preparation method and application thereof

A compound bacterial agent and bacillus technology, which can be applied to microorganism-based methods, biochemical equipment and methods, bacteria, etc., can solve problems such as spoilage and odor, proliferation of various microorganisms, and poor targeting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

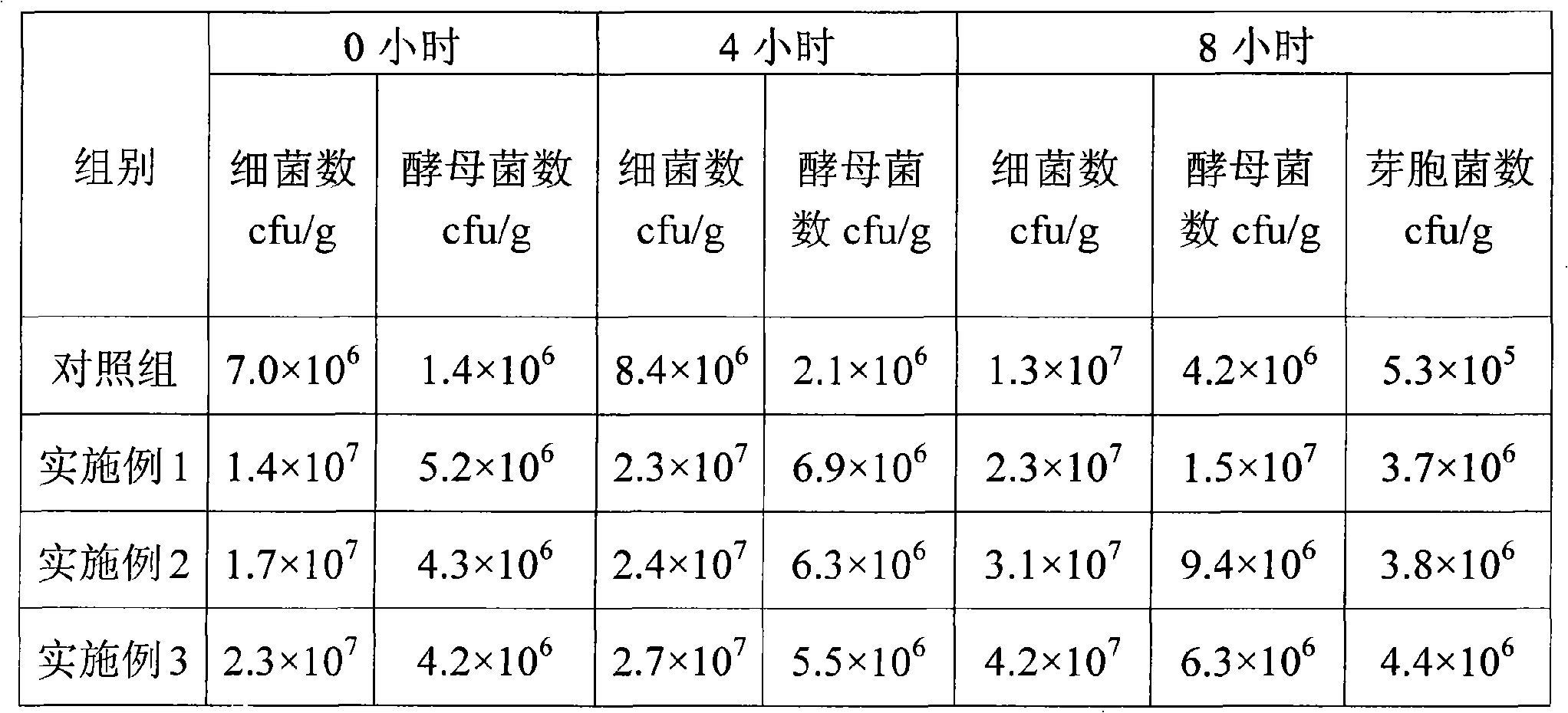

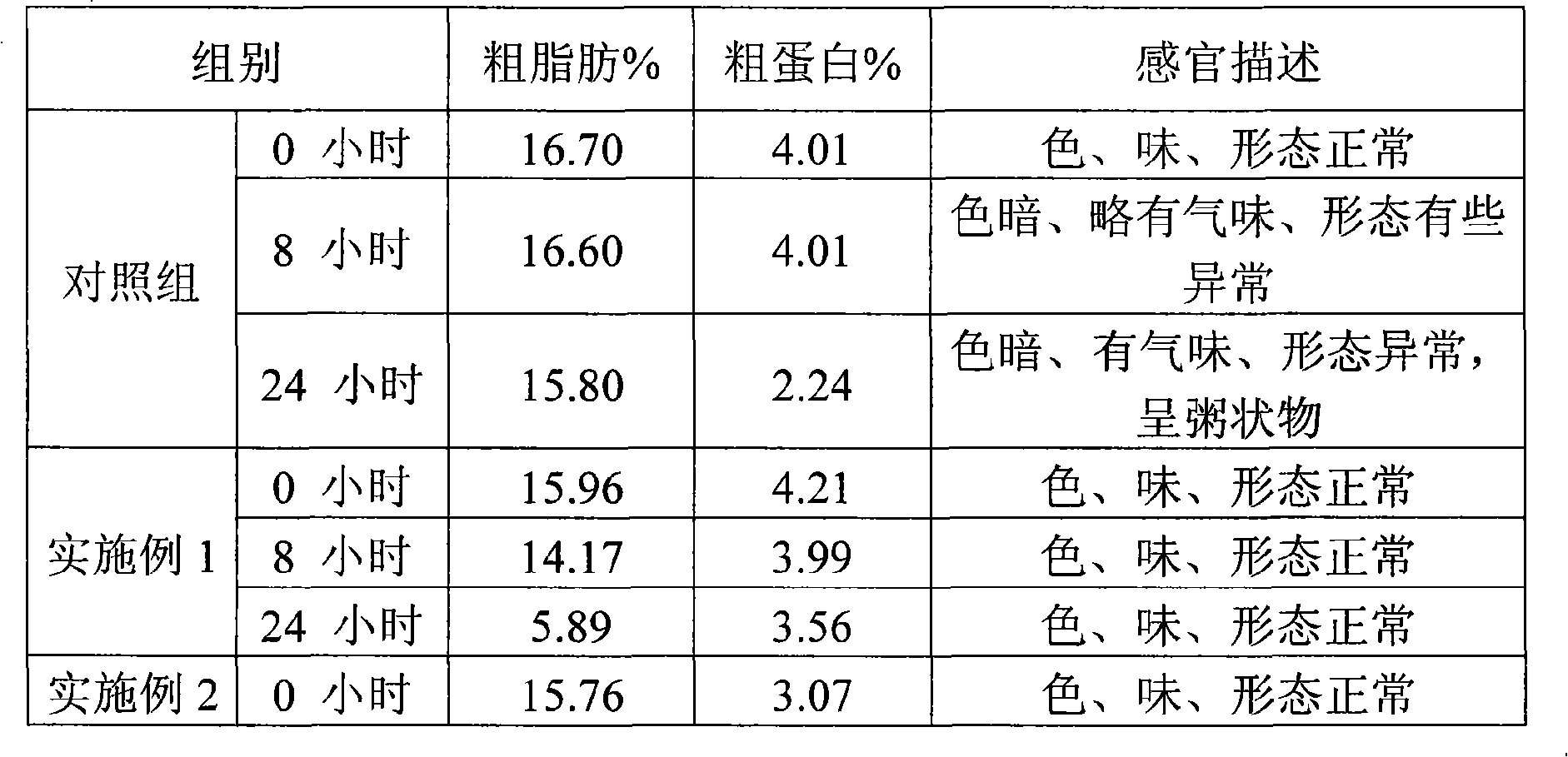

Embodiment 1

[0019] Bacillus stearothermophilus, Bacillus licheniformis, Zymomonas, Agrobacterium, Saccharomyces cerevisiae and Candida preserved at 4°C were respectively inoculated into ordinary broth liquid medium, the inoculation amount was 0.1% (v / v), Activation culture at 28-37°C for 8-18 hours; then transfer to common broth liquid medium, culture at 28-34°C for 8-18 hours, inoculum size 0.1-0.5% (v / v). After raising, each bacterial solution was mixed according to the following proportions: 15% of Bacillus stearothermophilus, 15% of Bacillus licheniformis, 12% of Zymomonas, 18% of Agrobacterium, 25% of Saccharomyces cerevisiae, 15% of Candida. Obtain the composite bacterial agent of embodiment 1.

Embodiment 2

[0021] Repeat the preparation steps of Example 1, after the activation culture, each bacterial solution is mixed in the following proportions: 20% of Bacillus stearothermophilus, 17% of Bacillus licheniformis, 13% of Zymomonas, 15% of Agrobacterium, 19% of Saccharomyces cerevisiae %, the ratio of Candida 16%, makes the composite bacterial agent of embodiment 2.

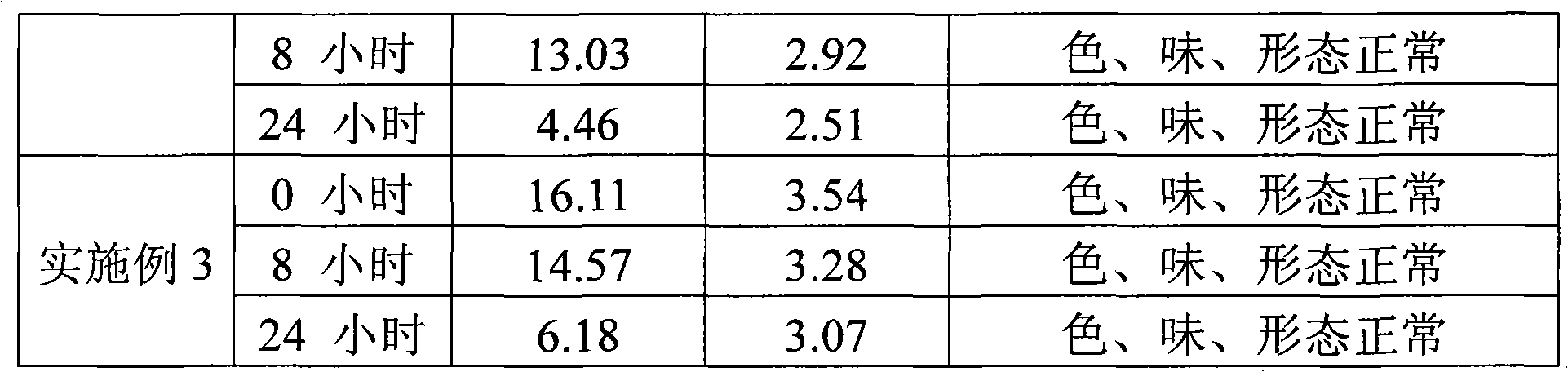

Embodiment 3

[0023] Repeat the preparation steps of Example 1, after the activation culture, each bacterial solution is mixed in the following proportions: 30% of Bacillus stearothermophilus, 15% of Bacillus licheniformis, 12% of Zymomonas, 13% of Agrobacterium, 20% of Saccharomyces cerevisiae %, the ratio of Candida 10%, the composite bacterial agent of embodiment 3 is made.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com