Polycrystal SiGe gate nano CMOS integrated circuit preparation based on SiO2 masking technique

An integrated circuit and nanoscale technology, applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve the problems of increased difficulty and limited adjustment range of device threshold voltage, so as to reduce the difficulty of the process, realize the adjustment, and reduce the process steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

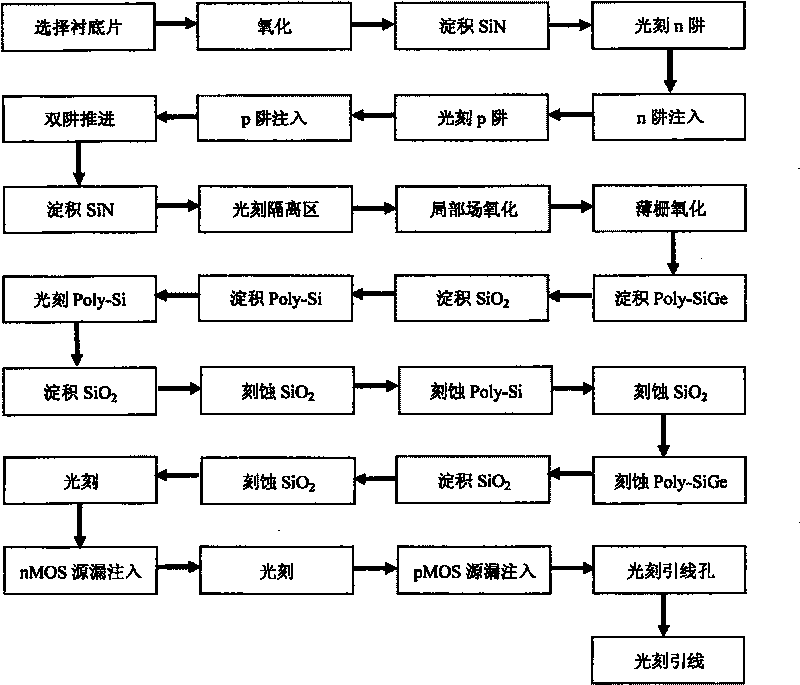

[0032] Embodiment 1: the CMOS integrated circuit with the polycrystalline SiGe gate that the conductive channel is prepared on the Si substrate is 75nm, and concrete steps are as follows:

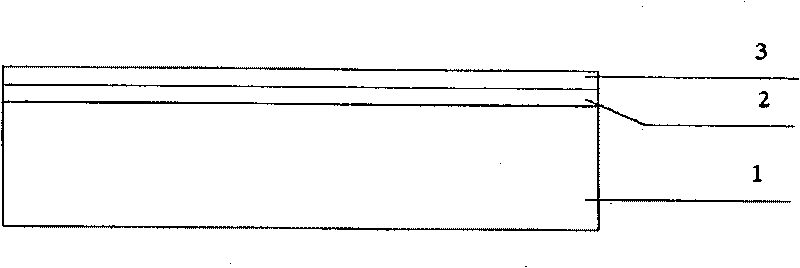

[0033] Step 1, deposit a masking layer, such as figure 2 (a) shown.

[0034] (1a) Select the crystal orientation as and the doping concentration as 10 15 cm -3 Left and right p-type Si substrate sheets 1;

[0035] (1b) Thermally oxidize a layer of SiO with a thickness of 40 nm on the substrate 2 buffer layer 2;

[0036] (1c) on SiO 2A 140nm-thick SiN layer 3 is deposited on the buffer layer by plasma-enhanced chemical vapor deposition (PECVD) for the masking of well implantation.

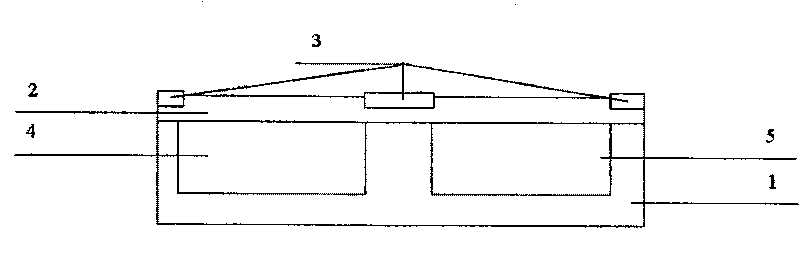

[0037] Step 2, forming a well region, such as figure 2 (b) shown.

[0038] (2a) Photoetching the P well region 4 and the N well region 5 on the SiN layer 3 according to the phase sequence;

[0039] (2b) Boron is implanted in the P well region to form a p-type region, and SiO is thermally oxidized on t...

Embodiment 2

[0067] Embodiment 2: on the SOI substrate, the CMOS integrated circuit with the polycrystalline SiGe gate with a 65nm conductive channel is prepared, and the specific steps are as follows:

[0068] Step 1, deposit a masking layer, such as figure 2 (a) shown.

[0069] (1a) Select the crystal orientation as and the doping concentration as 10 15 cm -3 left and right p-type SOI substrates 1;

[0070] (1b) Thermally oxidize a layer of SiO with a thickness of 30 nm on the substrate 2 buffer layer 2;

[0071] (1c) on SiO 2 A 120nm-thick SiN layer 3 is deposited on the buffer layer by atmospheric pressure chemical vapor deposition (APCVD) for masking the implantation in the well region.

[0072] Step 2, forming a well region, such as figure 2 (b) shown.

[0073] (2a) Photoetching the P well region 4 and the N well region 5 on the SiN layer 3 according to the phase sequence;

[0074] (2b) Boron is implanted in the P well region to form a p-type region, and SiO is thermally ...

Embodiment 3

[0102] Embodiment 3: the CMOS integrated circuit with the polycrystalline SiGe gate that the conductive channel is 90nm is prepared on the Si substrate, the specific steps are as follows:

[0103] Step 1, deposit a masking layer, such as figure 2 (a) shown.

[0104] (1a) Select the crystal orientation as and the doping concentration as 10 15 cm -3 Left and right p-type Si substrate sheets 1;

[0105] (1b) Thermally oxidize a layer of SiO with a thickness of 50 nm on the substrate 2 buffer layer 2;

[0106] (1c) on SiO 2 A 160nm-thick SiN layer 3 is deposited on the buffer layer by low-pressure chemical vapor deposition LPCVD method, which is used for the masking of well implantation.

[0107] Step 2, forming a well region, such as figure 2 (b) shown.

[0108] (2a) Photoetching the P well region 4 and the N well region 5 on the SiN layer 3 according to the phase sequence;

[0109] (2b) Boron is implanted in the P well region to form a p-type region, and SiO is therm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com