Visible light nano bismuth magnesium composite oxides photocatalyst and preparation method thereof

A composite oxide, photocatalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of limited types of photocatalysts and achieve good applications Prospects, Promotion of Practicalization, Efficient Photocatalytic Degradation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

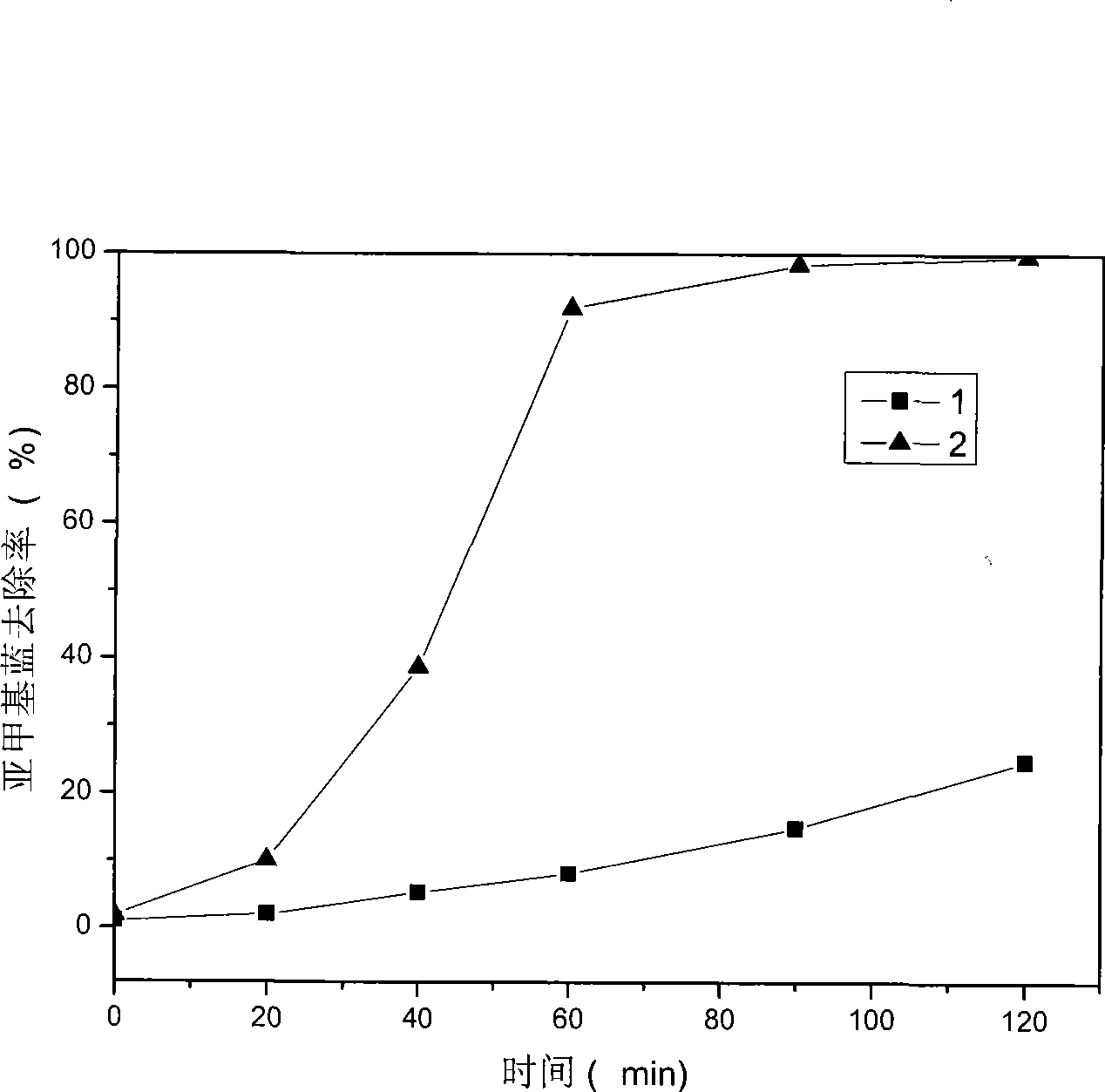

Examples

Embodiment 1

[0022] Visible light nano bismuth magnesium composite oxide photocatalyst, it comprises the steps:

[0023] 1) Take by weighing 0.1264 gram of sodium bismuthate, according to the mol ratio of magnesium chloride and sodium bismuthate is 5:1, choose magnesium chloride and sodium bismuthate, standby; Make 0.05 mol / L magnesium chloride solution with deionized water; Bismuth acid Add sodium into the prepared magnesium chloride solution in the form of solid powder, stir the mixed solution for 20 minutes, and mix well to obtain a suspension;

[0024] 2) Transfer the above suspension into a 100ml stainless steel reaction kettle lined with polytetrafluoroethylene, add deionized water to 70ml, the filling degree is 70%, do not add hydrochloric acid, at the natural pH value (8-9) Put it in a constant temperature oven after closing the lid tightly, and keep it at 130°C for 6 hours;

[0025] 3) After cooling to room temperature, the reacted product was taken out, washed with deionized wat...

Embodiment 2

[0030] Visible light nano bismuth magnesium composite oxide photocatalyst, it comprises the steps:

[0031] 1) Take by weighing 0.1264 gram of sodium bismuthate, according to the mol ratio of magnesium chloride and sodium bismuthate is 5:1, choose magnesium chloride and sodium bismuthate, standby; Make 0.05 mol / L magnesium chloride solution with deionized water, mix bismuthate Sodium was added into the magnesium chloride solution in the form of solid powder and fully mixed (stirred for 20 minutes) to obtain a suspension;

[0032] 2) Transfer the above suspension into a stainless steel reaction kettle lined with polytetrafluoroethylene, the volume of the reaction kettle is 100 ml, add water to 70 ml, the filling degree is 70%, adjust the pH value to 4 with hydrochloric acid, and cover tightly Put the kettle cover into a constant temperature oven and keep it at 130°C for 6 hours;

[0033] 3) After cooling to room temperature, the reacted product was taken out, washed twice by c...

Embodiment 3

[0036] Visible light nano bismuth magnesium composite oxide photocatalyst, it comprises the steps:

[0037] 1) Take by weighing 0.1264 gram of sodium bismuthate, according to the mol ratio of magnesium chloride and sodium bismuthate is 5:1, choose magnesium chloride and sodium bismuthate, standby; Make 0.05 mol / L magnesium chloride solution with deionized water, mix bismuthate Sodium was added into the magnesium chloride solution in the form of solid powder and fully mixed (stirred for 20 minutes) to obtain a suspension;

[0038] 2) Move the above-mentioned suspension into a stainless steel reaction kettle lined with polytetrafluoroethylene, the volume of the reaction kettle is 100 milliliters, add deionized water according to the hydrothermal reaction filling degree of 70%, without adding hydrochloric acid, at natural pH value (8-9); put the kettle lid tightly and put it in a constant temperature oven, and keep it at 140°C for 4 hours;

[0039] 3) After cooling to room tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com