Electric spark micro hole processing control method

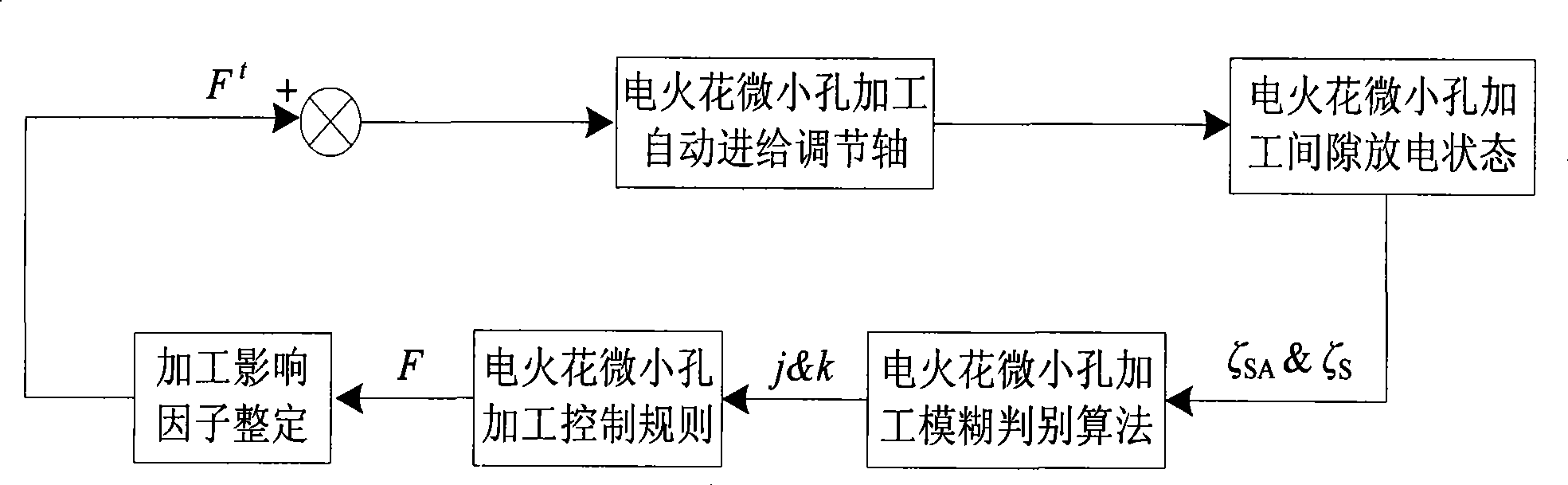

A control method and micro-hole technology, applied in the direction of electric processing equipment, adaptive control, general control system, etc., can solve the problems of serious calculation time-consuming, simplification, servo feed can not track the processing status in real time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0050] The processing experimental conditions are as follows: the electrode material is brass, the electrode diameter is 0.1mm, the workpiece material is 45# steel, the workpiece thickness is 1mm, high and low voltage composite processing (high voltage 255V, low voltage 94V), pulse width 5μs, pulse interval 25μs, processing capacitance 4700pF and 2200pF are connected in parallel, the working fluid is kerosene, positive polarity machining, the spindle speed r=667 rpm; the data sampling frequency of the electric signal of the discharge gap is 2MHz.

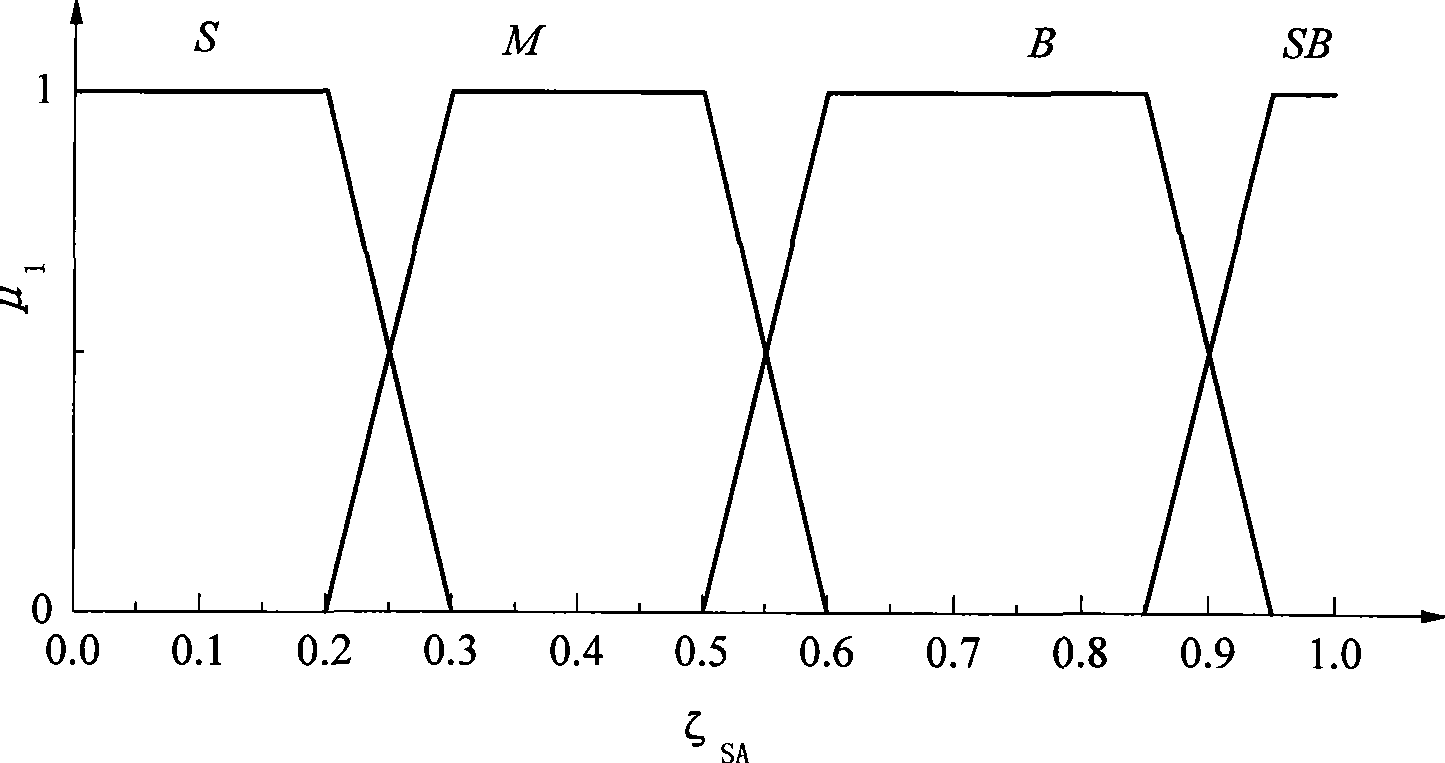

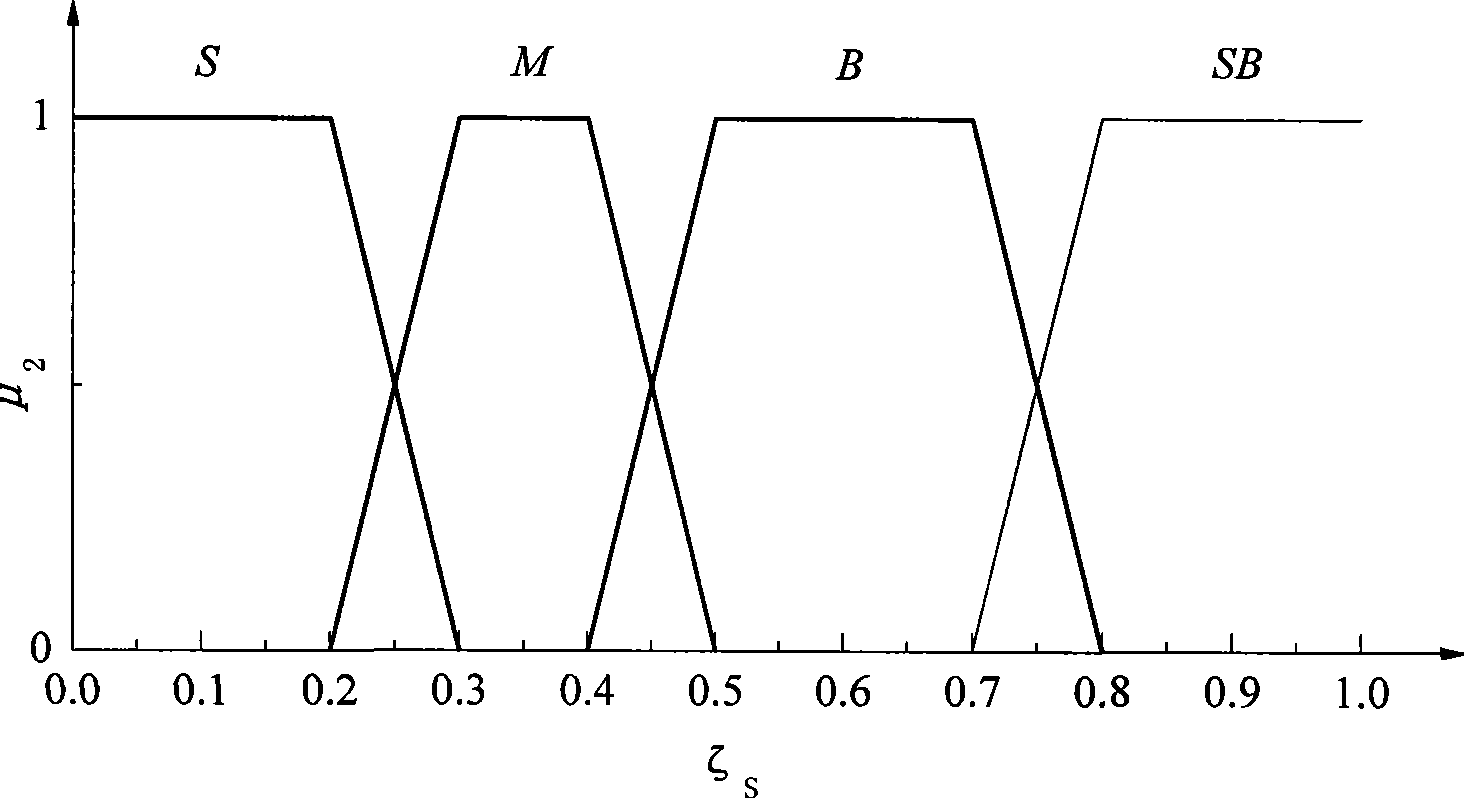

[0051] First, take ζ in any analysis cycle under the processing conditions shown above SA and ζ S As an input quantity, its membership function is as follows: figure 2 and image 3 shown. Assume that at this time in the analysis period ζ SA and ζ S The degree of membership is:

[0052] μ A S ( ζ SA ...

Embodiment approach 1

[0061] Embodiment 1 In the EDM micro-hole machining system with the machining conditions as shown above, the 250Ω current-limiting resistor of the pulse power supply is turned on, the machining current is about 0.5A, and the traditional automatic feed control method based on the average voltage method is used to process the hole. The times for 1, 2, and 3 are respectively 1085s, 1130s, and 1201s, with an average time of 1138s; using the processing control method proposed by the present invention, the processing times for holes 4, 5, and 6 are respectively 1054s, 996s, and 1020s, with an average time of 1023s. Through the comparison of the results of Embodiment 1, it can be seen that when the machining current is about 0.5A for machining, the difference between the average machining efficiency of the two groups and the percentage of the average machining efficiency of the second group are calculated. The processing time of the traditional automatic feed control method of the ave...

Embodiment approach 2

[0062] Embodiment 2 Turn on the 125Ω current-limiting resistor of the pulse power supply, the processing current is about 0.88A, adopt the traditional automatic feed control method based on the average voltage method, and the processing time of holes 7, 8, and 9 is 894s, 865s, and 907s respectively. The time spent is 889s; using the processing control method proposed by the present invention, the time for processing holes 10, 11, and 12 is 689s, 715s, and 667s respectively, and the average time is 690s. Through comparison of the results of Embodiment 2, it can be seen that when the processing current is about 0.88A for processing, the difference between the average processing efficiency of the two groups and the percentage of the average processing efficiency of the second group are calculated. The processing time of the traditional automatic feed control method of the average voltage method is shortened by 199s, and the processing efficiency is increased by 28.8%.

[0063] Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com