Downhole linear electric motor oil-well pump

A technology of linear motors and linear motors, applied in the field of oil well pumps and downhole linear motor oil pumps, can solve the problems of short service life, unreasonable structure, stuck mover, etc., and achieve the goal of eliminating large deflection, reasonable structure and improving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

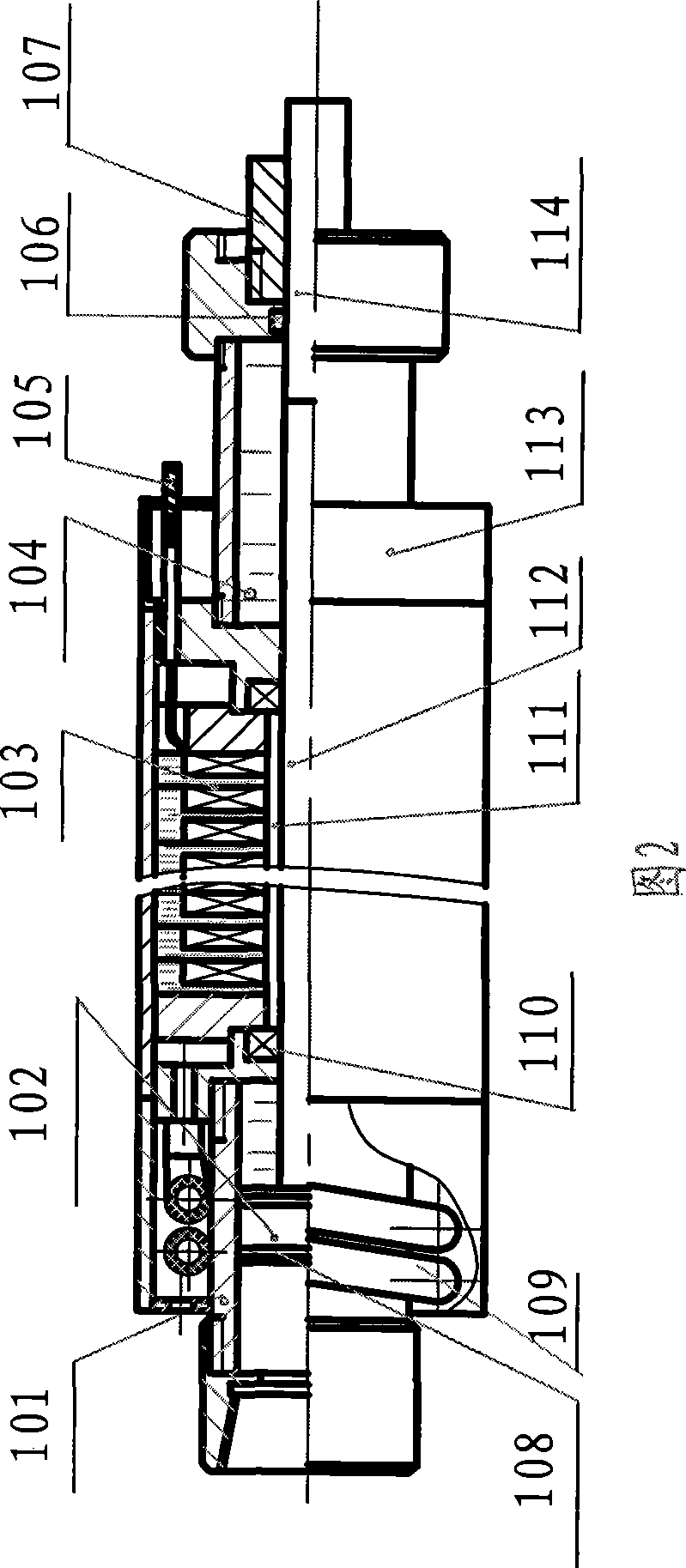

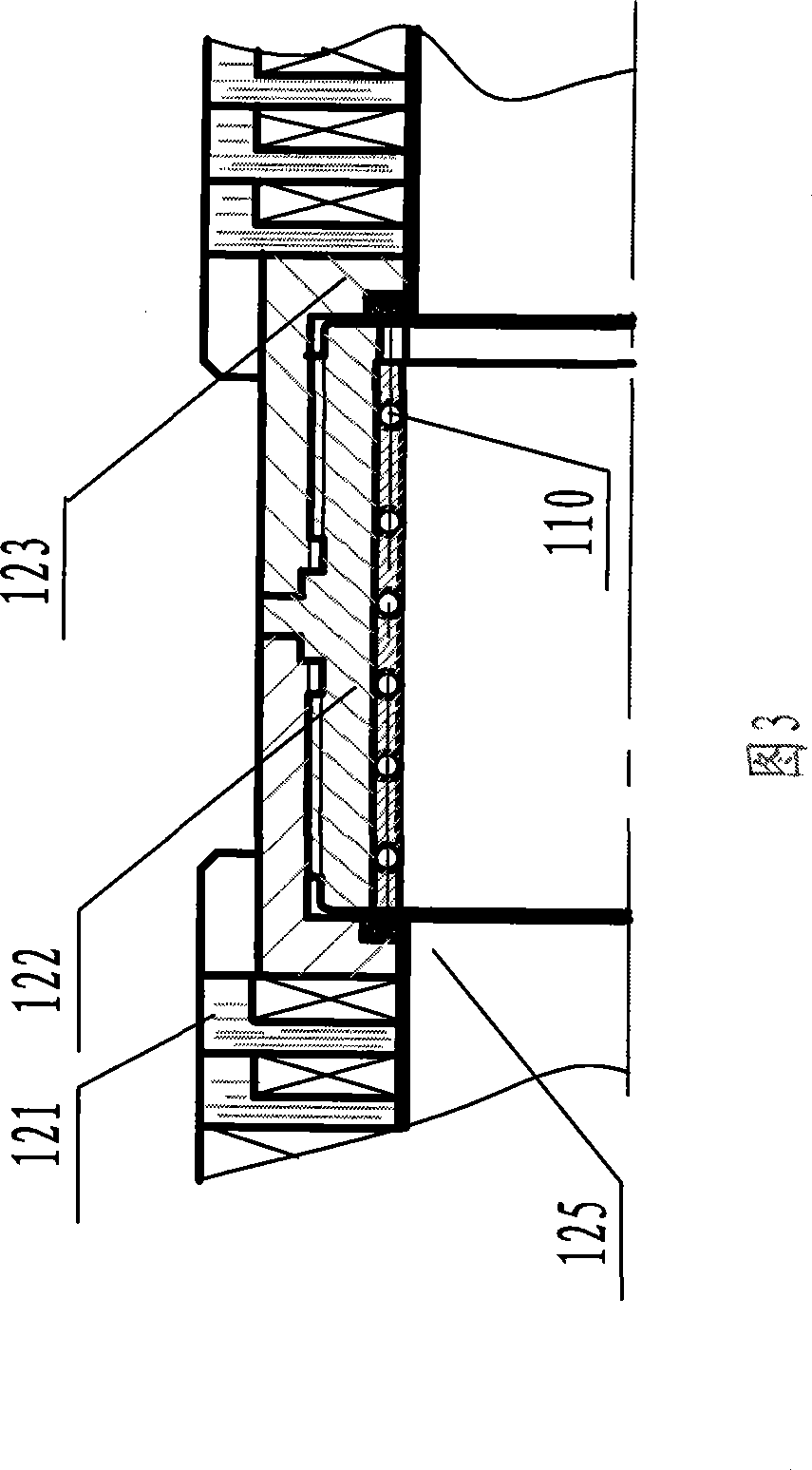

[0035]Referring to Fig. 9, Fig. 10 and Fig. 11, the currently used linear motor oil pump has the following defects: the linear motor air gap 305 has no protection measures, crude oil enters the air gap 305, and the silt mixed in the crude oil is deposited in the air gap, and the The mover 301 moving in a straight line is stuck; the chemical components in the crude oil corrode the permanent magnet on the mover 301, causing the magnet 308 to lose its magnetism and stop the motor. After the corroded magnet 308 expands, because the mover 301 is stuck in the air gap 305, the linear motor stops working; because the winding 303 is sealed with the motor casing 302 and the armature inner sleeve 304, the armature 307 is filled with Transformer oil, after the motor works normally, the temperature rises and the transformer oil expands, and the armature is deformed because there is no pressure relief device, causing the mover to sweep, damage the inner sleeve, crude oil enters the winding, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com