Process and apparatus for preparing diethyl carbonate

A technology of diethyl carbonate and a process method is applied in the field of technology and equipment for producing diethyl carbonate, and can solve problems such as a large amount of ethanol circulating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

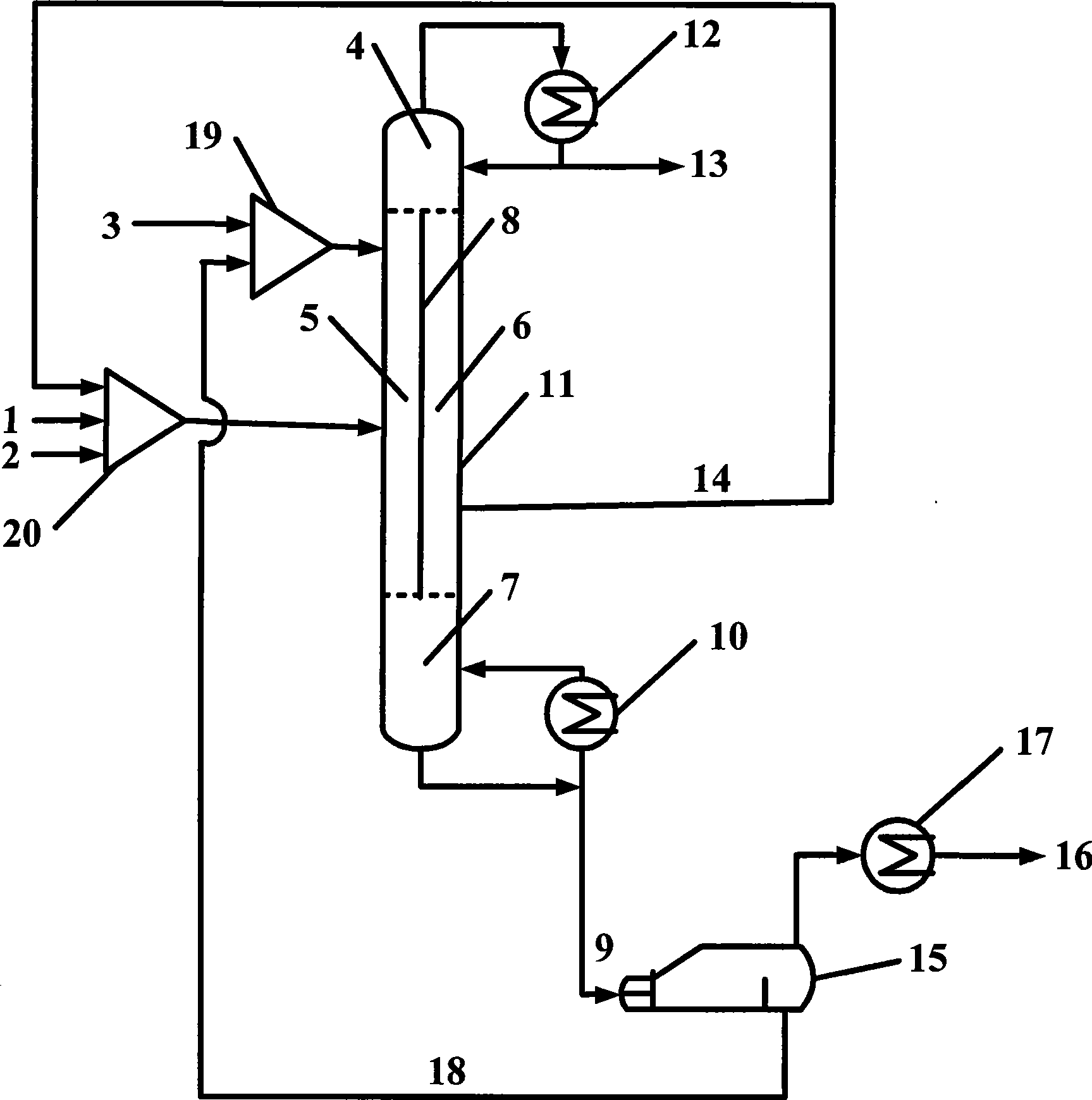

[0025] Embodiment 1: as figure 1 process shown.

[0026] In a process equipment mainly composed of reactive distillation dividing wall column (11), condenser (12,17), reboiler (10), evaporator (15), mixer (19,20), raw material carbonic acid Diethyl carbonate is prepared from dimethyl ester and ethanol under the action of catalyst potassium carbonate.

[0027] The reactive distillation dividing wall column (11) is a tray column with a diameter of 2000 mm and a height of 22000 mm. The internal actual tray arrangement: 9 public rectification sections (4), 16 reaction sections (5), and 16 side line sections (6) , 15 pieces of public stripping section (7).

[0028] Reactive distillation dividing wall column (11) operating conditions:

[0029]Fresh feed dimethyl carbonate enters the middle part of the reaction section (4) of reactive distillation dividing wall column (11) with the mass flow rate of 1414.8kg / h, ethanol with the mass flow rate of 1447.1kg / h, and catalyst salt of wo...

Embodiment 2

[0030] Embodiment 2: as figure 1 process shown.

[0031] In a process equipment mainly composed of reactive distillation dividing wall column (11), condenser (12,17), reboiler (10), evaporator (15), mixer (19,20), raw material carbonic acid Diethyl carbonate is prepared from dimethyl ester and ethanol under the action of catalyst sodium hydroxide.

[0032] The reactive distillation dividing wall tower (11) is a packed tower with a diameter of 1600mm and a height of 18000mm. The height of the packing layer is: public rectification section (4) 2600mm, reaction section (5) 4600mm, side line section (6) 4600mm, public stripping section (7) 4300mm.

[0033] Reactive distillation dividing wall column (11) operating conditions:

[0034] The feeding position, raw material and catalyst feeding amount are the same as in Example 1, the tower top reflux ratio is 6, the tower top temperature is 64.5°C, the tower bottom temperature is 126.8°C, the reaction zone temperature is 76.1~100.9°...

Embodiment 3

[0035] Embodiment 3: as figure 1 process shown.

[0036] In a process equipment mainly composed of reactive distillation dividing wall column (11), condenser (12,17), reboiler (10), evaporator (15), mixer (19,20), raw material carbonic acid Diethyl carbonate is prepared from dimethyl ester and ethanol under the action of catalyst potassium hydroxide.

[0037] The reactive distillation dividing wall column (11) is a tray column with a diameter of 2400 mm and a height of 23500 mm. The internal actual tray arrangement: 10 public rectification sections (4), 17 reaction sections (5), and 17 side line sections (6) , 16 blocks of common stripping section (7).

[0038] Reactive distillation dividing wall column (11) operating conditions:

[0039] The feeding position, raw material and catalyst feeding amount are the same as in Example 1, the top reflux ratio is 15, the tower top temperature is 64.5°C, the tower bottom temperature is 126.8°C, the reaction section temperature is 84.7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com