Biological consistent natural polymer hydrogel and preparation method thereof

A natural polymer and biocompatible technology, applied in the field of biocompatible natural polymer hydrogel and its preparation, to achieve the effects of good air permeability and flexibility, superior hydrophilicity, and no side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

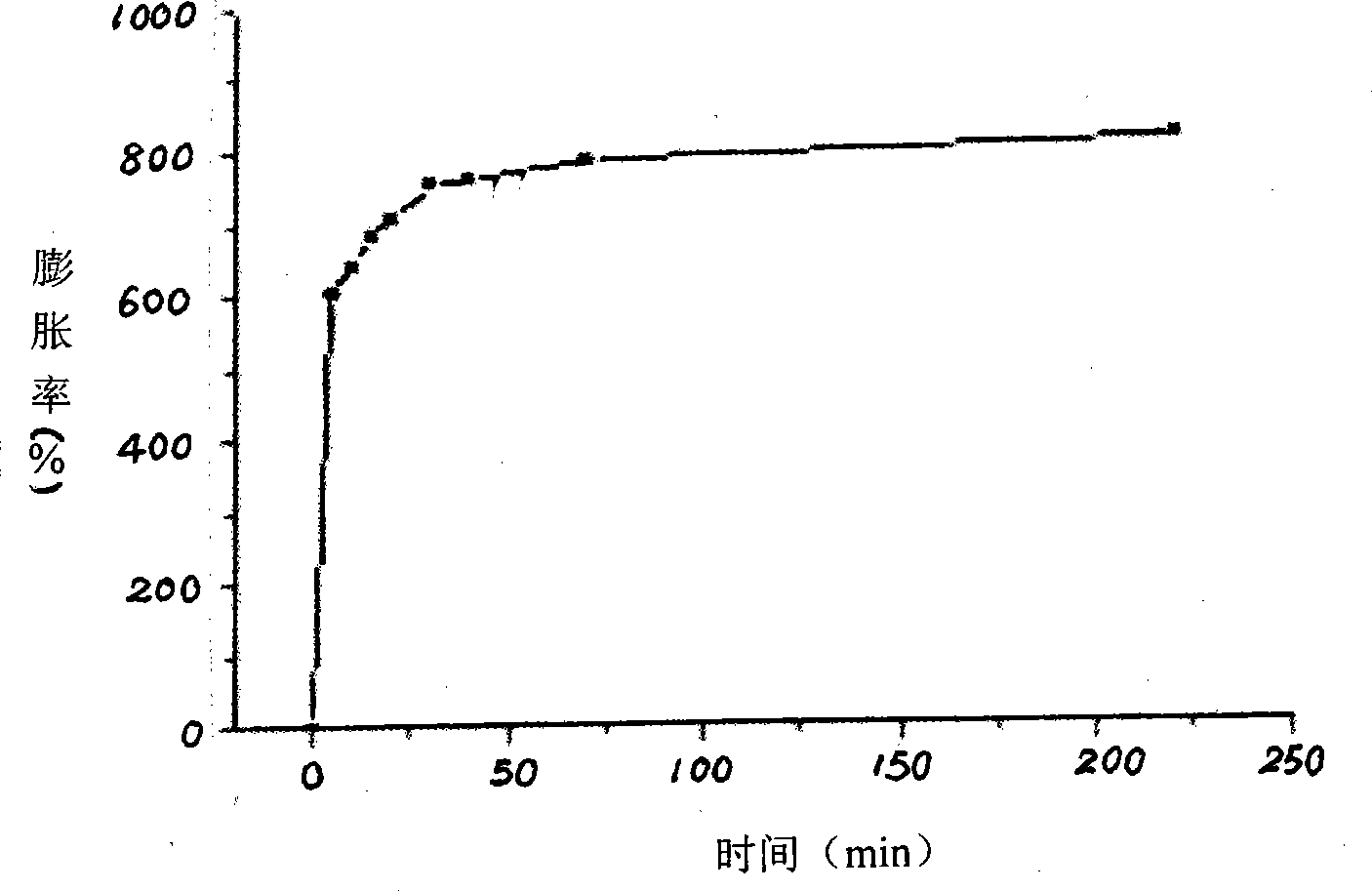

Image

Examples

Embodiment 1

[0032] A method for preparing a biocompatible natural polymer hydrogel, comprising the steps of:

[0033] (1) Disperse chitosan and 1-hydroxybenzotriazole with a molar ratio of 1:4 in water, so that the mass percent concentration of chitosan is 2%, and stir until a transparent solution is formed;

[0034] (2) With chitosan and N-acetyl-L-cysteine at a mass ratio of 1:5, add N-acetyl-L-cysteine to the above solution, and then add the chitosan and shell In an aqueous solution prepared with 1-ethyl-(3-dimethylaminopropyl)carbodiimide equal to the mass of polysaccharide, adjust the pH to 5, and stir at 20°C for 3 hours;

[0035] (3) Take out the reaction solution, and dialyze 3 times with 5mmol / L hydrochloric acid aqueous solution containing 2μmol / L EDTA in 3 days at 12°C in the dark, and then dialyze 3 times with 5mmol / L hydrochloric acid aqueous solution containing 1g / L NaCl, It was then dialyzed three times with 1mmol / L hydrochloric acid aqueous solution.

[0036] The pre...

Embodiment 2

[0040] A method for preparing a biocompatible natural polymer hydrogel, comprising the steps of:

[0041] (1) Disperse dextran and 1-hydroxybenzotriazole in a molar ratio of 1:1 in water so that the mass percent concentration of dextran is 1%, and stir until a transparent solution is formed;

[0042] (2) With dextran and 2,3-dimercaptosuccinic acid in a mass ratio of 1:0.5, add 2,3-dimercaptosuccinic acid to the above solution, and then add it dropwise with dextran In an aqueous solution prepared with an equal mass of 1-ethyl-(3-dimethylaminopropyl)carbodiimide, adjust the pH to 6, and stir at 15°C for 4h;

[0043] (3) Take out the reaction solution, and dialyze twice with 5mmol / L hydrochloric acid aqueous solution containing 2μmol / L EDTA within 4 days at 8°C in the dark, and then dialyze 5 times with 5mmol / L hydrochloric acid aqueous solution containing 1g / L NaCl, It was then dialyzed 5 times with 1mmol / L hydrochloric acid aqueous solution.

Embodiment 3

[0045] A method for preparing a biocompatible natural polymer hydrogel, comprising the steps of:

[0046] (1) Disperse gelatin and 1-hydroxybenzotriazole in a molar ratio of 1:8 in water so that the mass percent concentration of gelatin is 3%, and stir until a transparent solution is formed;

[0047] (2) With gelatin and N-acetyl-L-cysteine at a mass ratio of 1:10, add N-acetyl-L-cysteine to the above solution, and then add gelatin equal mass In the aqueous solution prepared with 1-ethyl-(3-dimethylaminopropyl)carbodiimide, adjust the pH to 4, and stir at 25°C for 2h;

[0048] (3) Take out the reaction solution, and dialyze it 4 times with 5mmol / L hydrochloric acid aqueous solution containing 2μmol / L EDTA within 2 days at 15°C in the dark, and then dialyze it twice with 5mmol / L hydrochloric acid aqueous solution containing 1g / L NaCl, Then dialyze twice with 1mmol / L hydrochloric acid aqueous solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com