Ignition control carburetor of internal combustion engine

An ignition control and carburetor technology, which is applied in spark ignition controllers, carburetors, engine ignition, etc., can solve the problems of complex structure, mutual interference of magnetic sensors, high manufacturing cost, etc., achieve simple and compact structure, improve the overall The effect of low performance and manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

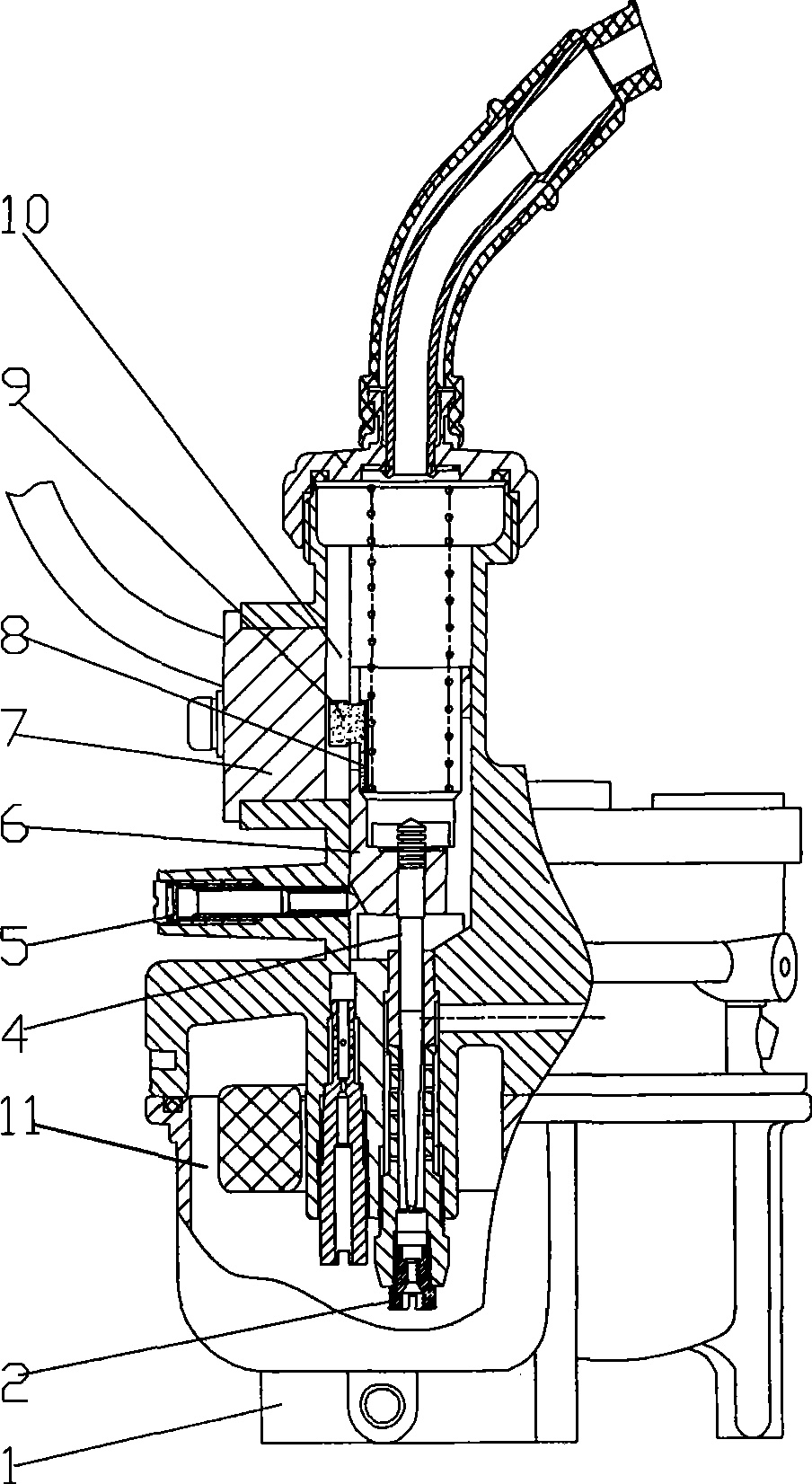

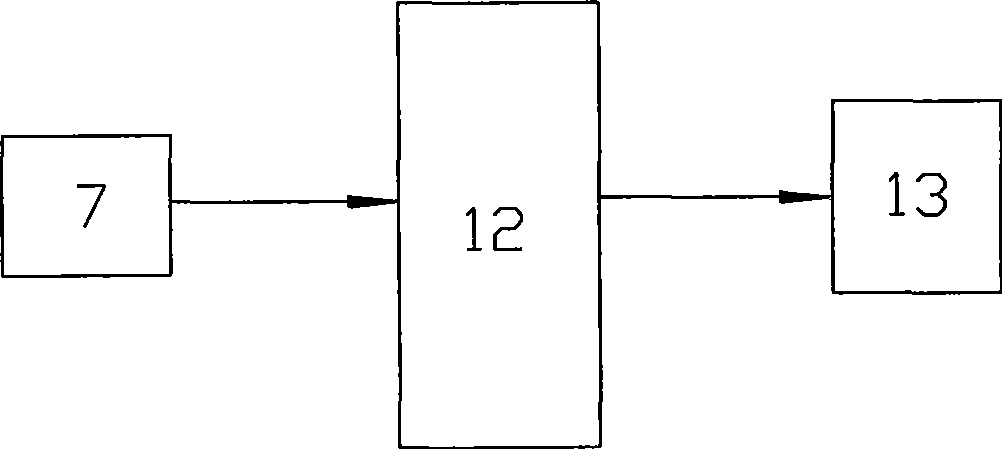

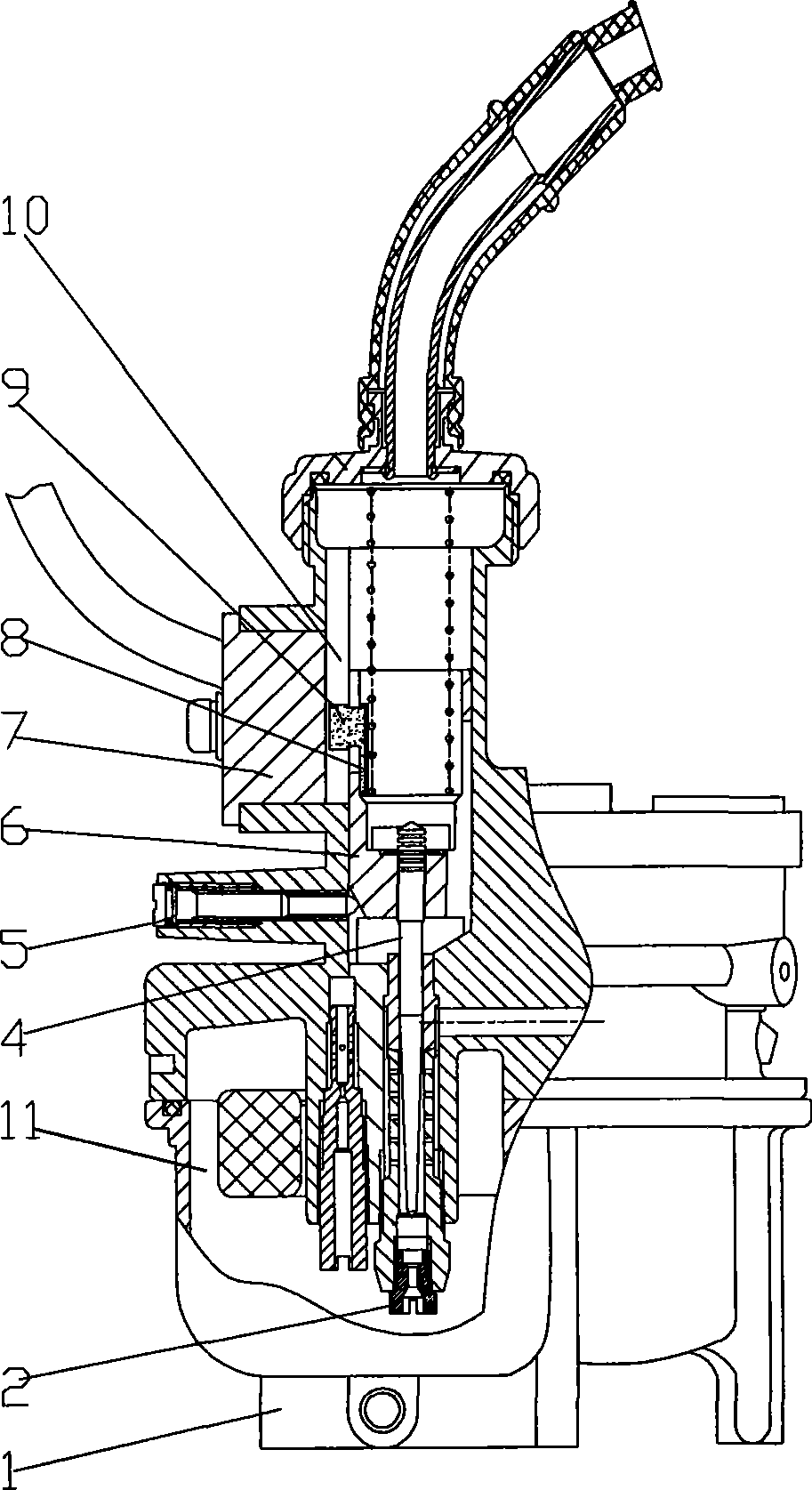

[0013] figure 1 It is a structural schematic diagram of the present invention, as shown in the figure: the internal combustion engine ignition control carburetor of this embodiment is an internal combustion engine carburetor for motorcycles, including a carburetor body 1, an air intake system, an oil intake system and an idle speed adjustment system 5 , the oil inlet system includes a float chamber 11, a main nozzle 2, an oil needle 4 and a plunger 6 axially fixedly connected to the oil needle 4, and the plunger 6 is arranged in the plunger chamber 10 in an axially movable manner, It also includes a Hall position sensor 7 and a permanent magnet 9, the Hall position sensor 7 is arranged on the wall of the plunger cavity 10, the permanent magnet 9 is arranged on the plunger 6 opposite to the Hall position sensor 7 in radial position, the permanent magnet 9 and the The radial gap between the Hall position sensors 7 is 2-3mm. If the gap is too small, the signal acquisition accurac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com