Method for detecting whether present layer aligning with anterior layer of chip

A technology for detecting chips and current layers, applied in the direction of semiconductor/solid-state device testing/measurement, etc., can solve the problems of chip waste manpower and material resources, chip deformation, chip performance degradation, etc., to save manpower and material resources, improve production efficiency, improve performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

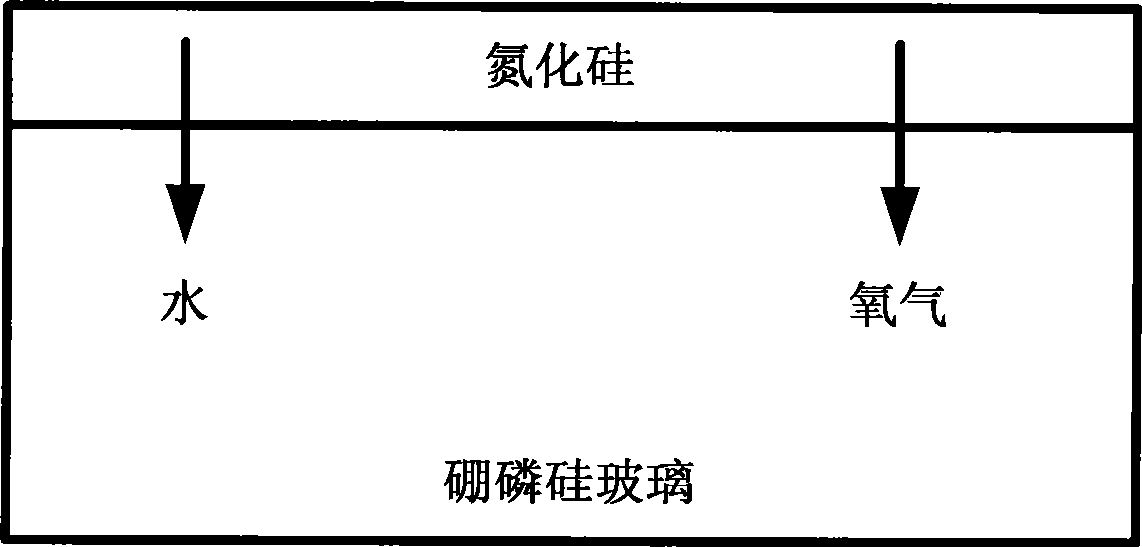

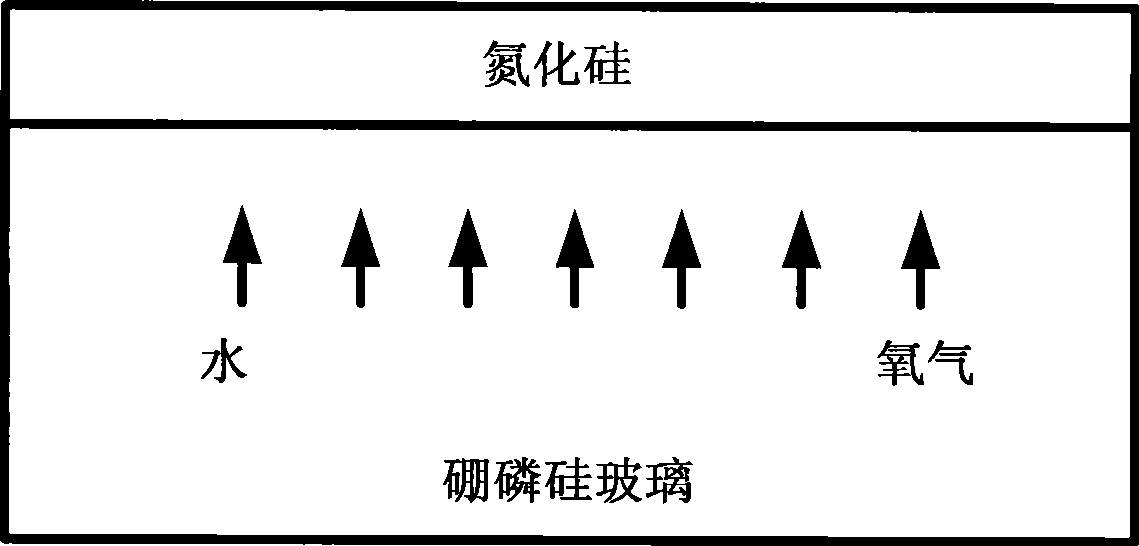

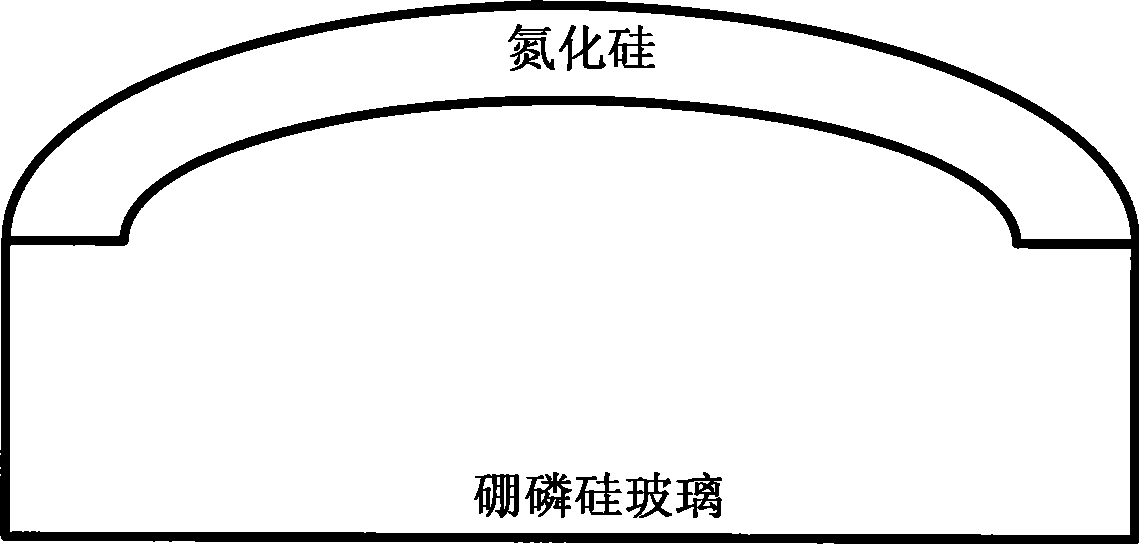

[0017] An embodiment of the present invention is aimed at solving the problem of water and oxygen leakage from the machine caused by chip deformation when growing silicon nitride in the machine.

[0018] Figure 4 It is a flow chart of steps of the present invention. Such as Figure 4 As shown, the present invention comprises the following steps: Step 1, mark on the surface of the wafer to be tested, and expose the wafer to be tested in the lithography area to expose the marks of the current layer and the contrast layer; Step 2, use an overlay measuring instrument to measure the current layer And the marking of the control layer, and use the analysis software of the overlay measuring instrument to perform simulation calculations, and judge whether there is deformation through the measurement results.

[0019] The present invention needs to use an overlay m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com