Green light diode with interpenetration interaction structure and method of manufacturing the same

A diode and green light technology, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as changes in luminous intensity and luminous color, increased device manufacturing costs, and short device life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0124] The present invention will be further described below in conjunction with accompanying drawing:

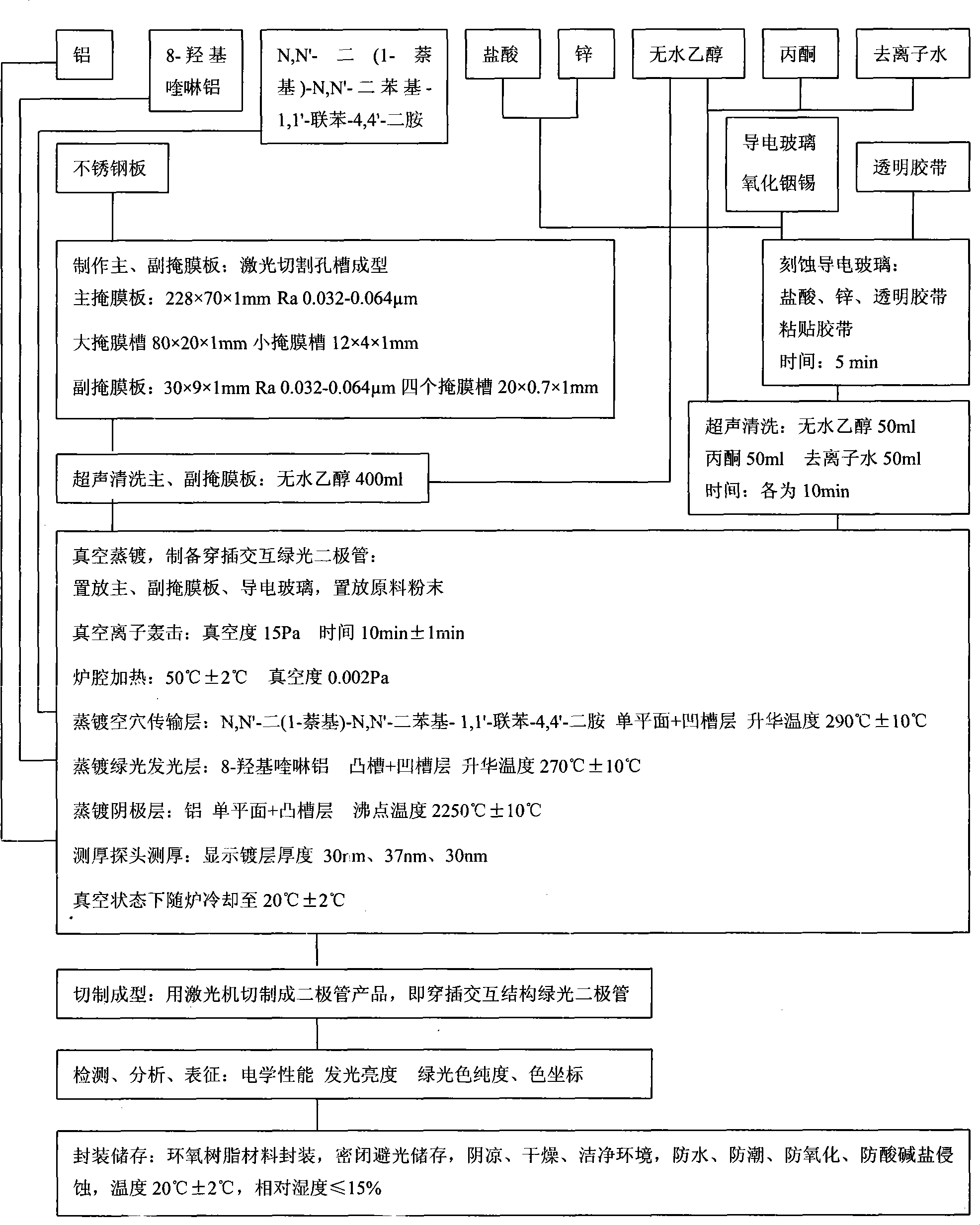

[0125] figure 1 Shown is the flow chart of the preparation process, which must be strictly carried out according to the preparation process parameters and operated step by step.

[0126] The amount of chemical substances required for preparation is determined within a preset range, with grams, milliliters, millimeters, micrometers, and nanometers as measurement units, and for industrial production, kilograms, liters, millimeters, micrometers, and nanometers The unit of measurement, the thickness of the flat layer and convex-concave layer of the green light diode is measured in nanometers.

[0127] Preparation of the desired N,N'-bis(1-naphthyl)-N,N'-diphenyl-1,1'-biphenyl-4,4'-diamine, 8-hydroxyquinoline aluminum, aluminum Strict weighing is required, and the fineness and purity are controlled, and no impurities are allowed to intervene to prevent the formation of by-pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com